Tamping wagon photoelectric measurement system and method

A photoelectric measurement and tamping vehicle technology, which is applied in the direction of measuring instruments, measuring devices, and optical devices, can solve the problems of measuring position deviation, reducing measurement accuracy, and poor anti-vibration environment, so as to avoid low measurement accuracy and improve Measurement accuracy, reducing the effect of power wave

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described below in conjunction with the accompanying drawings.

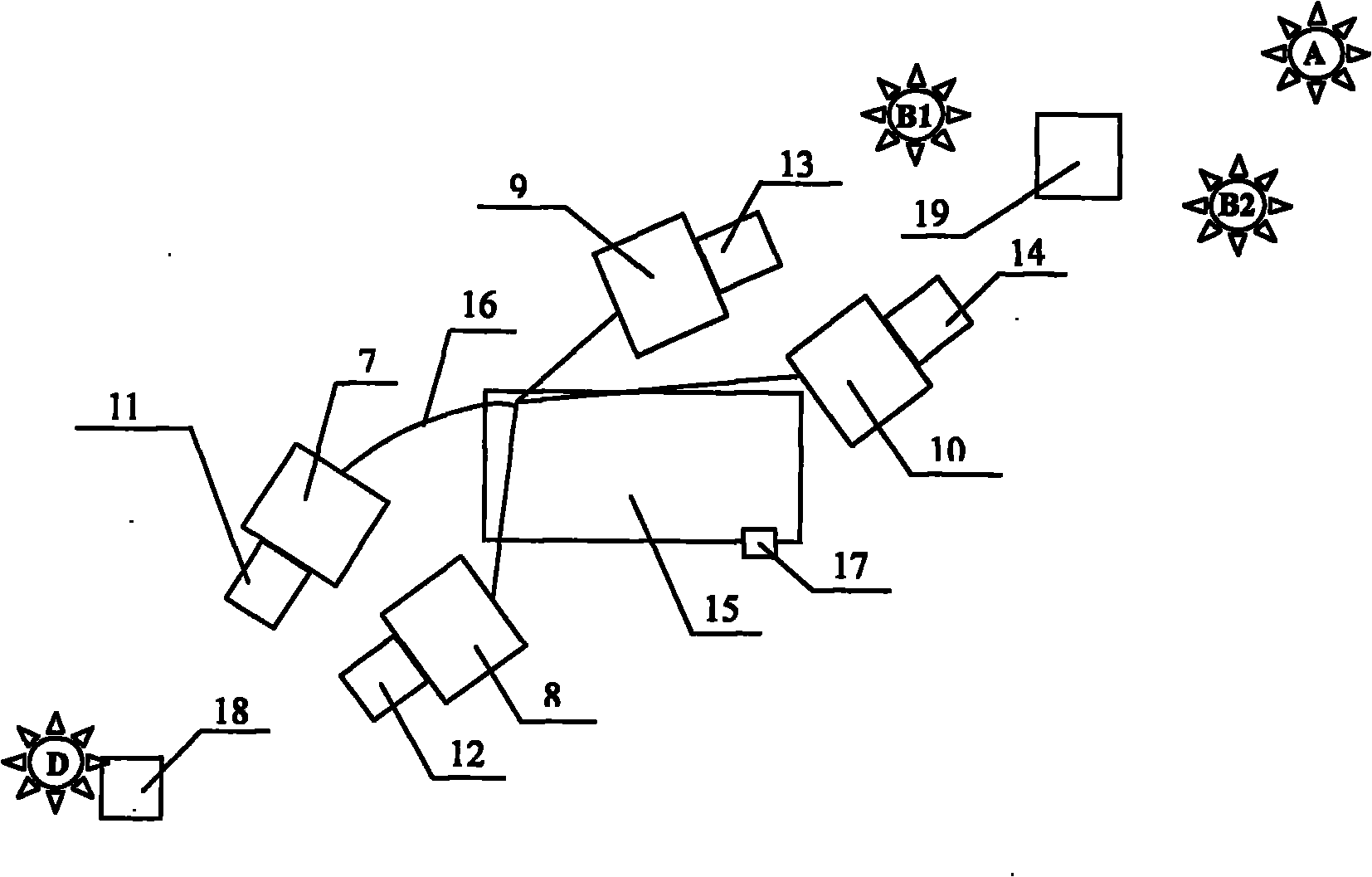

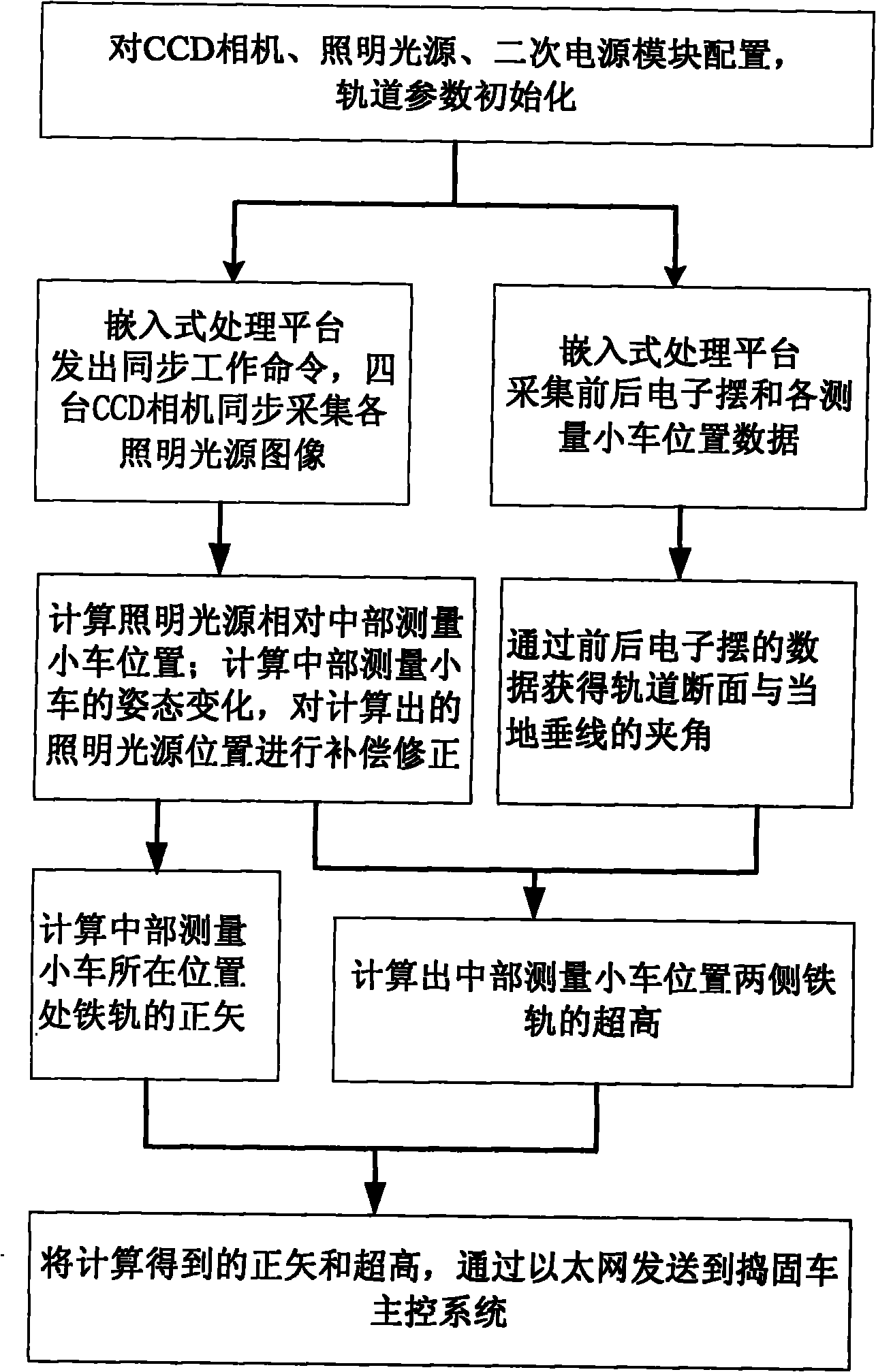

[0033] figure 1 It is a top-view structural schematic diagram of an embodiment of the tamping vehicle photoelectric measurement system of the present invention, including four measuring trolleys that move together with the tamping vehicle on the rail 1, that is, the terminal measuring trolley 2, the rear measuring trolley 3, and the middle measuring trolley 4 And the front measuring trolley 5, four measuring points A, B1, B2, D are set in turn on the measuring trolleys 2, 3, 5, and lighting sources are respectively set at the measuring points, the light source is a remote point light source, and the lighting source provides The high-brightness controllable light source used for measurement is the reference point for measurement. Laser light sources with small light spots and high brightness can be used. The lighting sources A and D are located on the center line of the rail se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com