Cutting machine in underwater pipeline

An underwater pipeline and cutting machine technology, applied in the direction of pipe shearing device, shearing device, attachment device of shearing machine, etc. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing, the present invention is described in more detail:

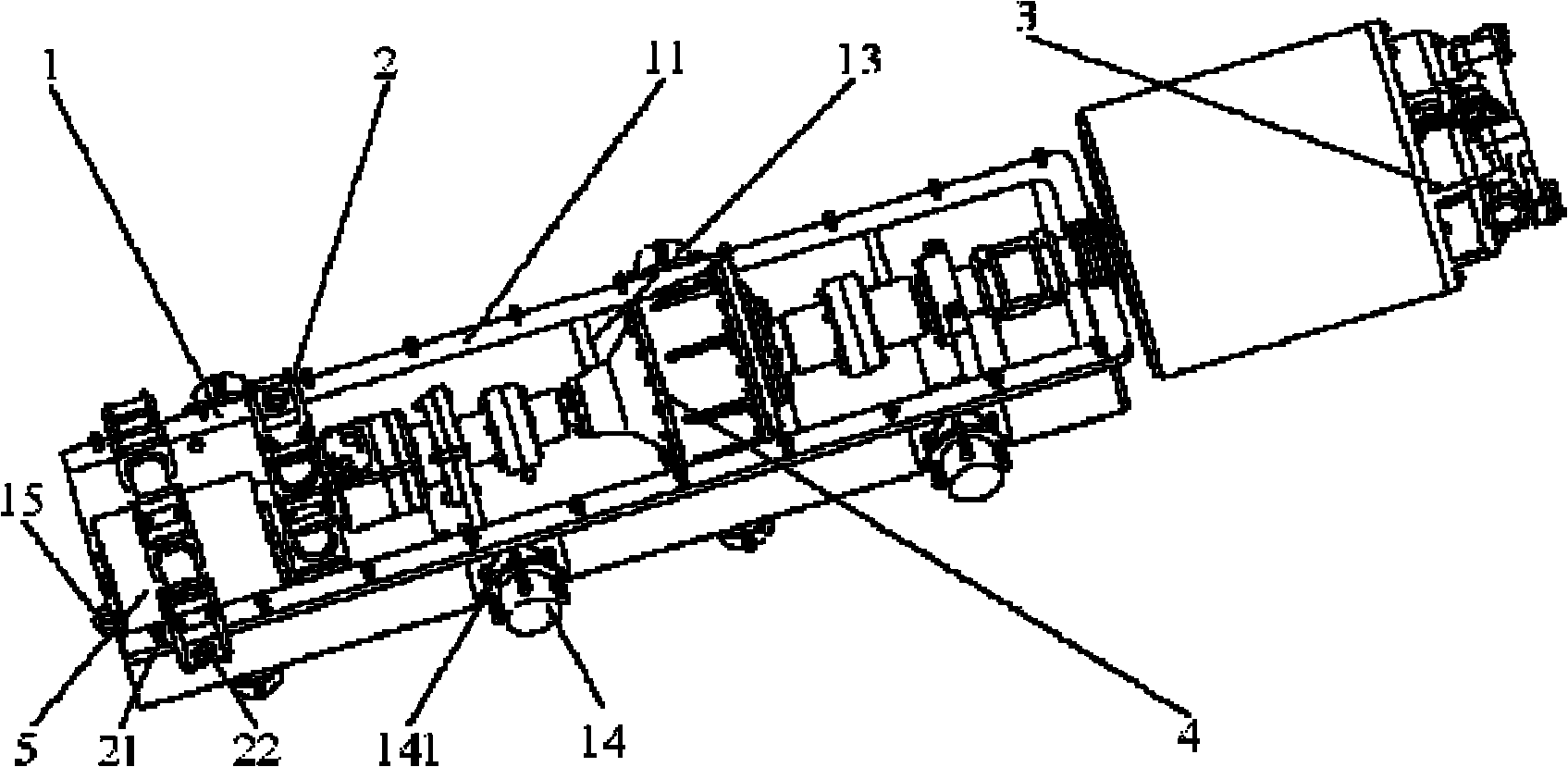

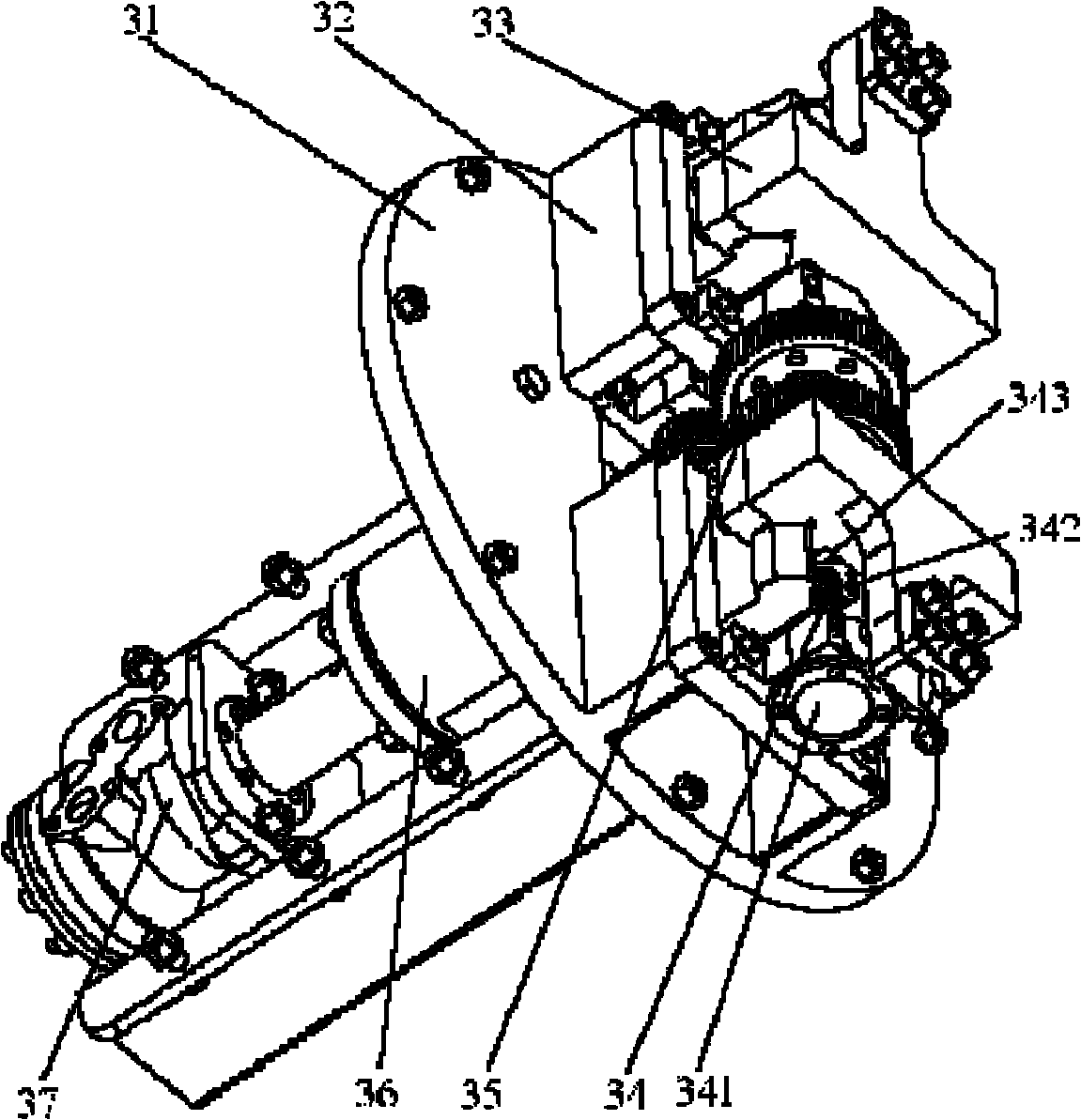

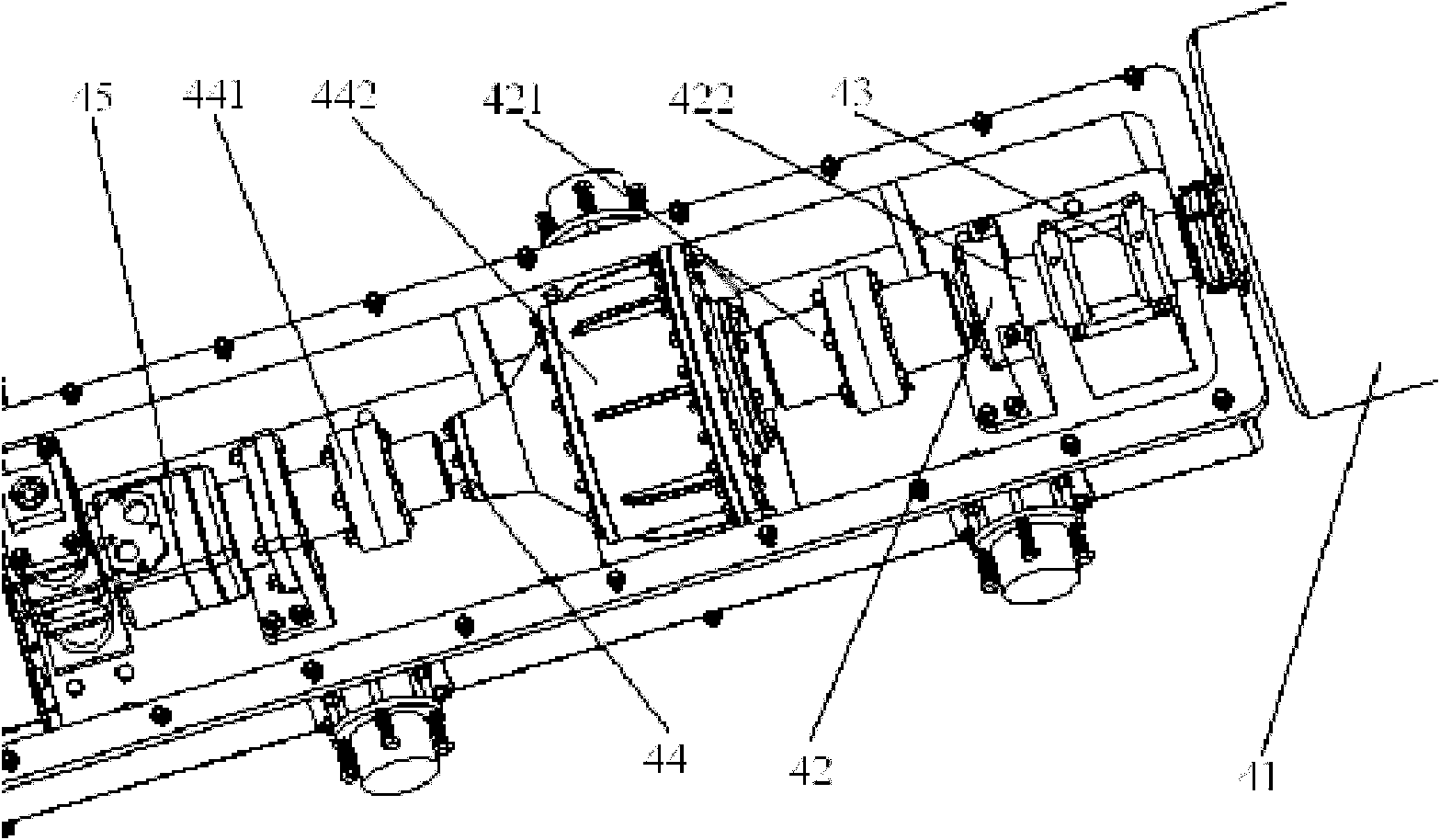

[0026] combine figure 1 and image 3 . The underwater pipeline internal cutting machine of the present invention mainly includes a box-type frame 1, a support device 2, a radial feed device 3, a cutting device 4, an underwater hydraulic control valve box and a detection system 5, and the like. It is placed in the pipe to be cut by the release device, and it is not limited by the position of the pipe during work. The support device 2, the drive part of the cutting device 4, the underwater hydraulic control valve box and the detection system 5 are installed in the box-type frame 1, and the radial feeding device 3 is driven by the cutting device 4. Part is connected with the box body.

[0027] Part 1 of the box-type frame is square in shape and adopts a split structure up and down, which is convenient for the assembly and maintenance of the whole machine. This part com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com