Lifting hook with gravity lever type anti-unhooking device

A lifting hook and anti-decoupling technology, which is applied in the field of lifting hooks, can solve the problems of artificial dismantling, anti-decoupling device failure, and insufficient strength, etc., to reduce work labor intensity, good market application prospects, and high device strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

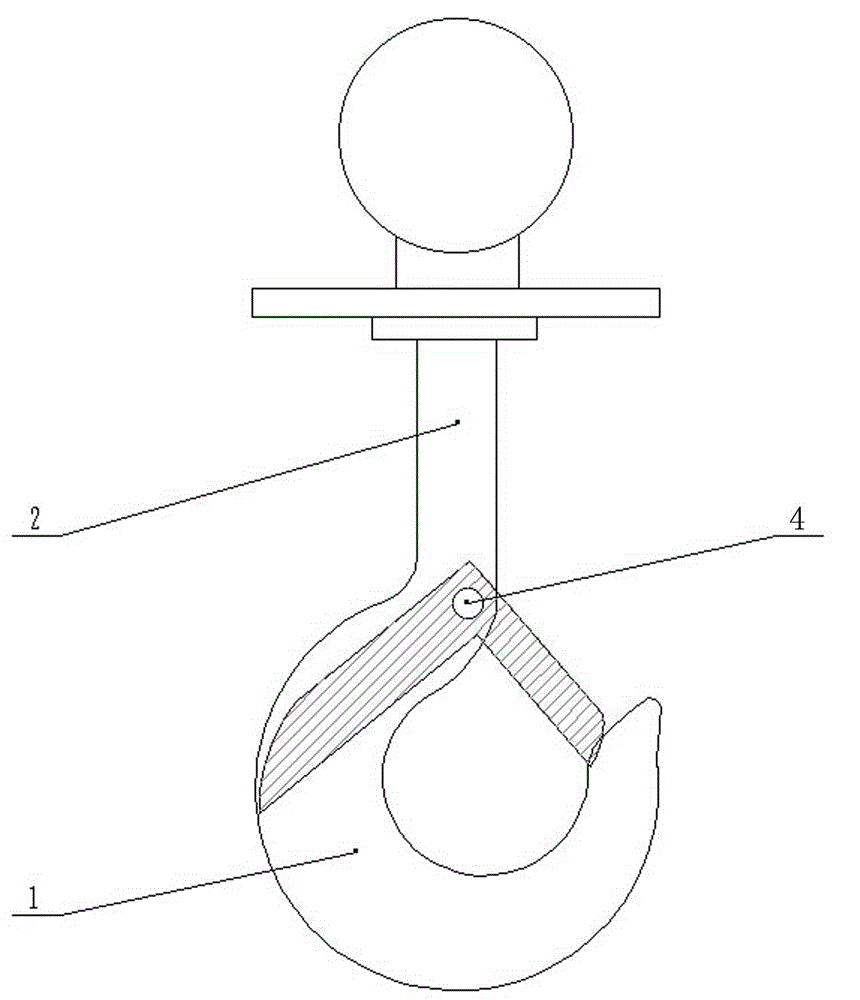

[0032] A lifting hook with a gravity lever type anti-decoupling device, such as figure 1 As shown, it includes a hook body 1 and a hook handle 2, and an anti-unhook device is installed at the junction of the hook body 1 and the hook handle 2; the anti-hook device includes a first short plate 11 and a first long plate 12, the The first short board 11 and the first long board 12 are connected at an acute angle; a second short board 21 and a second long board 22 are also included, and the second short board 21 and the second long board 22 are connected at an acute angle. Wherein, the size of the acute angle is determined by those skilled in the art according to the actual situation, as long as the gravity lever can be realized.

[0033] An anti-off plate 3 is connected between the ends of the first short plate 11 and the second short plate 12; the first short plate 11, the first long plate 21, the second short plate 21, and the second long plate 22 are symmetrical distribution, ...

Embodiment 2

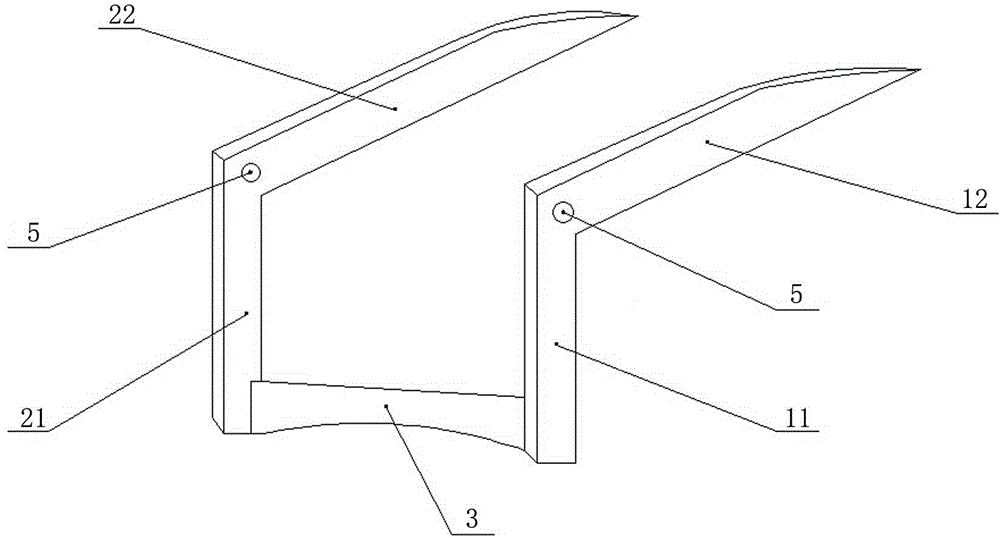

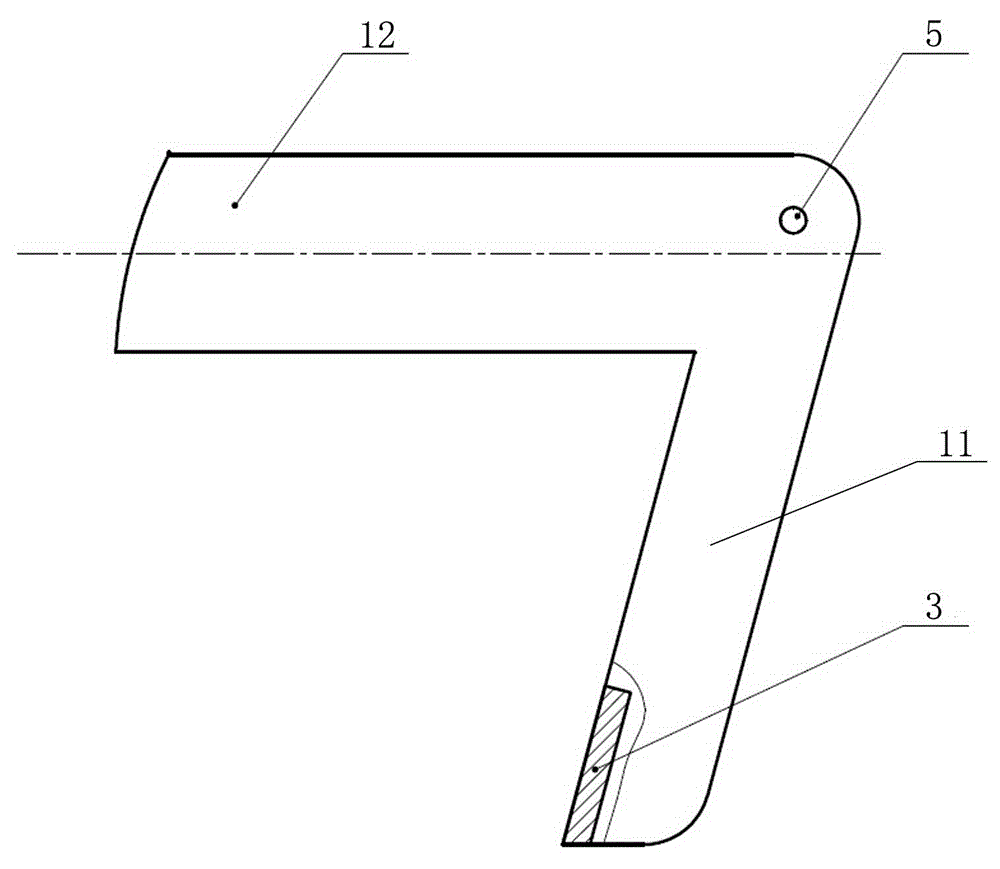

[0036] A gravity lever type lifting hook anti-decoupling device, such as figure 2 , 3 As shown, the first short plate 11 and the first long plate 12 are included, and the first short plate 11 and the first long plate 12 are connected at an acute angle by bolts or welded into an integral connection; it also includes the second short plate 21 and the first The second long plate 22, the second short plate 21 and the second long plate 22 form an acute angle and are fixedly connected by bolts or welded into one body. Wherein, the size of the acute angle is determined by those skilled in the art according to the actual situation, as long as the gravity lever can be realized.

[0037] An anti-off plate 3 is connected between the ends of the first short plate 11 and the second short plate 12; the first short plate 11, the first long plate 21 and the second short plate 21, the second long plate 22 are in the same The shapes are symmetrically distributed, and the joints of the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com