Imaging module

A camera module and camera element technology, applied in image communication, TV, color TV, etc., can solve the problems of lightweight limit, easy deformation of through-hole shape, unstable external structure and bracket, etc. The effect of reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

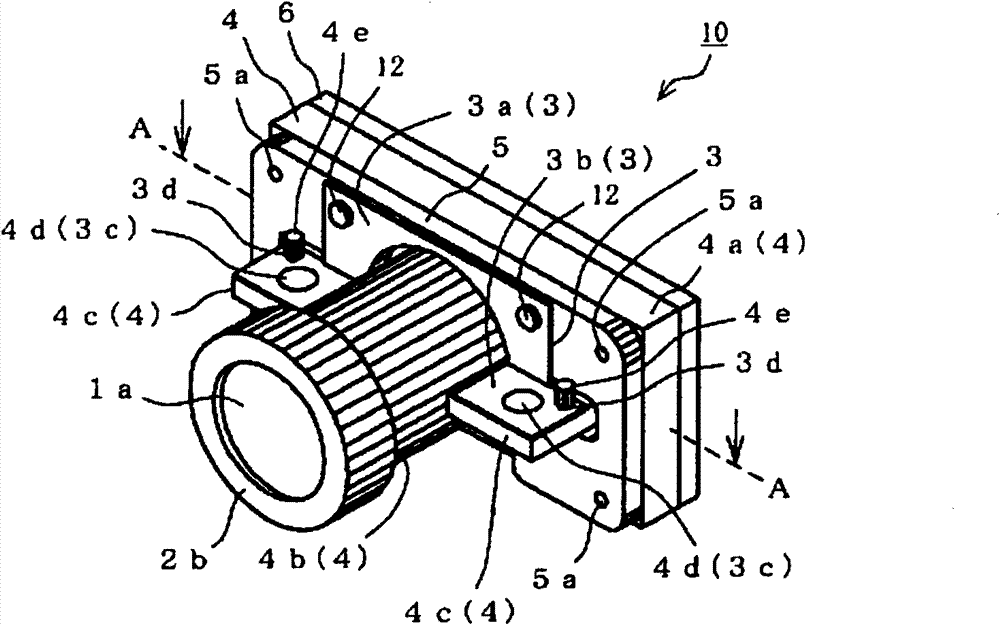

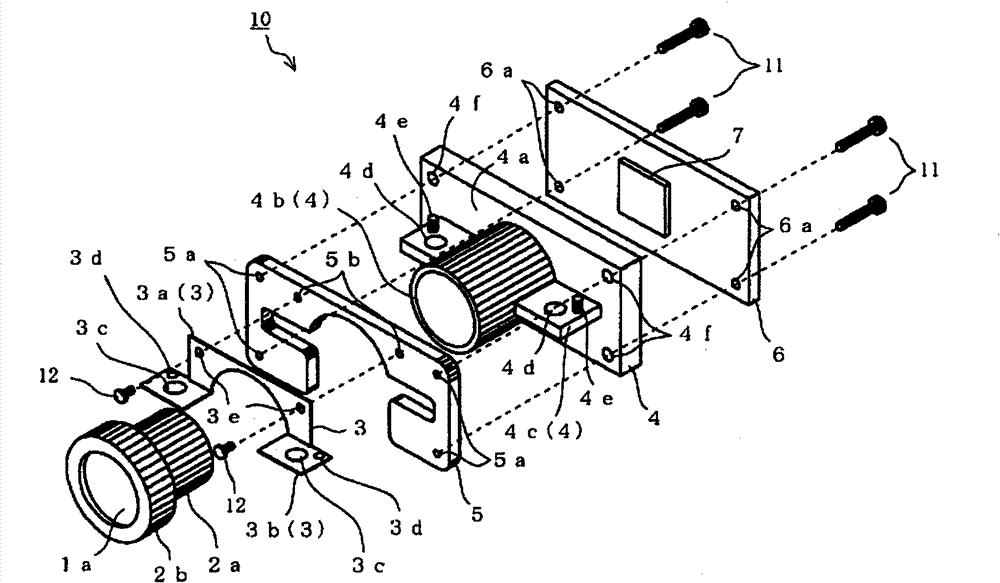

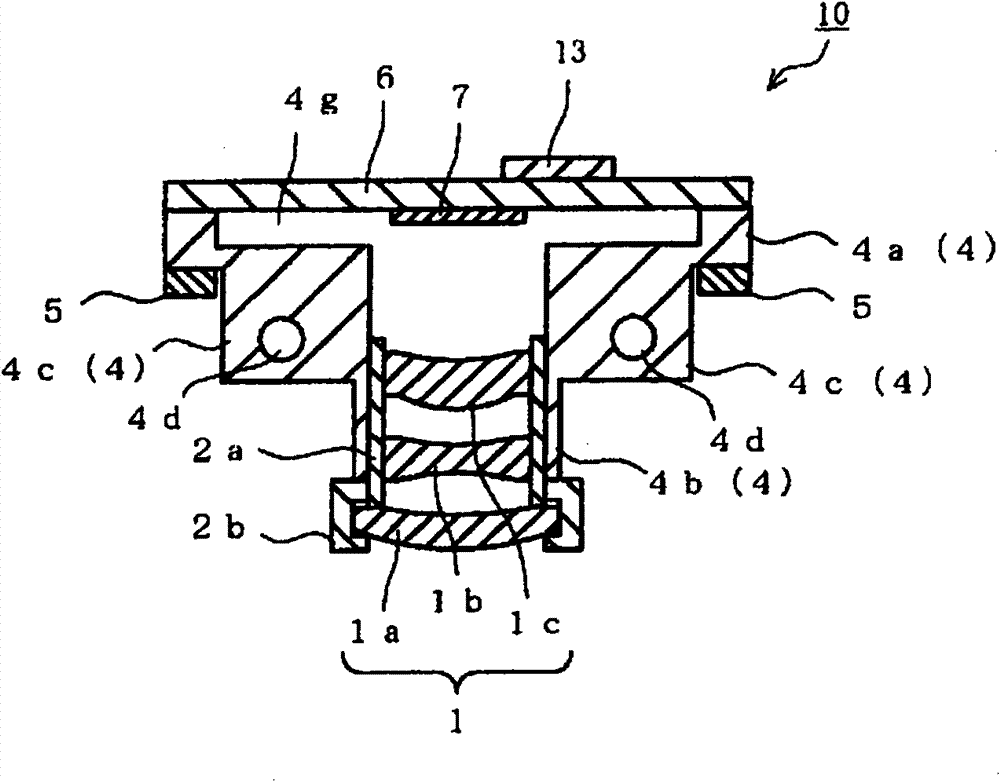

[0090] The camera module of the present invention was produced as follows.

[0091] First, a rectangular imaging substrate 6 is prepared. The imaging substrate 6 is provided with through holes 6a at four corners, has a longitudinal length of 20 mm, a lateral length of 40 mm, and a thickness of 1.6 mm. The imaging element 7 is mounted on the principal surface on the imaging body side, and the connector 13 and IC are mounted on the principal surface on the rear side.

[0092] Next, a resin material made of polyphthalamide is processed to produce a bracket 4 having a rectangular shape with through holes 4 f formed at four corners, a vertical length of 20 mm, a horizontal length of 40 mm, and a thickness of 4.0 mm. The substrate fixing portion 4a, the lens support cylindrical portion 4b with a diameter of 15mm formed with screw grooves on the inner wall, and the holding portion 4c provided with a through hole 4d with a diameter of 3.5mm.

[0093] Next, a stainless steel plate wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com