A method for fabricating thin films

A technology for thin films and thin film materials, applied in the field of thin film preparation, can solve problems such as low thermal conductivity and low ablation threshold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

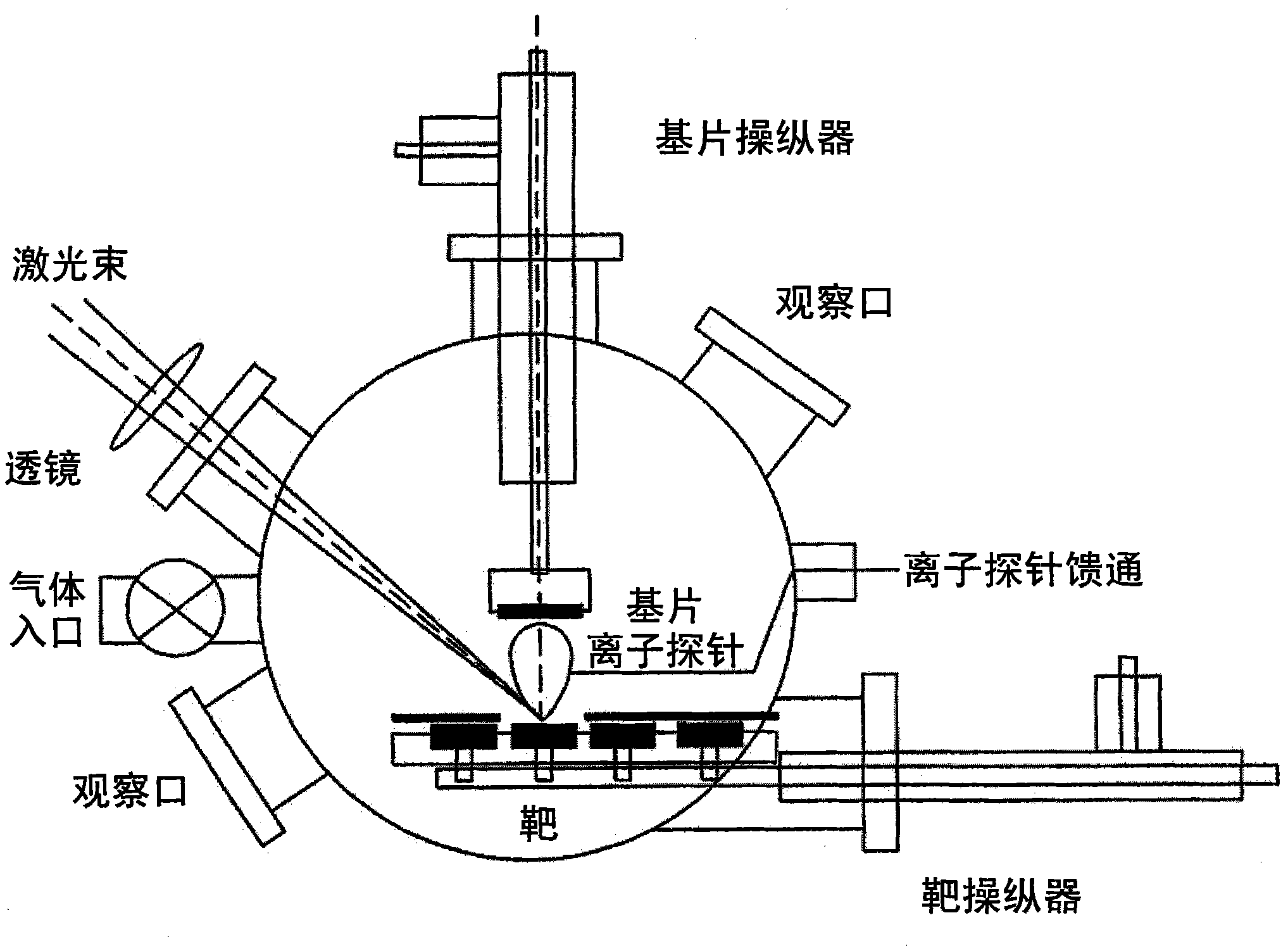

Image

Examples

Embodiment Construction

[0053] Embodiments of the present PLD invention generally use bursts of pulses for material synthesis to tune or otherwise control material morphology. For example, one or more laser pulses can be used to prepare thin films to create a distribution of nanoparticles with a single ultrashort pulse. Bursts of other pulses can be used to produce smooth, nearly grain-free films. The burst parameters, or parameters of the pulses in a burst, can be based on known target emission characteristics. For example, burst widths of tens of nanoseconds, hundreds of nanoseconds, and up to several microseconds in combination with pulse widths in the range of about 50 fs to about 100 ps may be used. Typically, the first pulse at least initiates a laser interaction with the target material, and at least the second pulse interacts with by-products of said interaction. The interaction may be laser ablation and the by-product may include a plume comprising charged and neutral particles.

[0054] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com