Fluorine-containing polymer and water- and oil-repellent agent

A water- and oil-repellent agent and polymer technology, which can be used in fabrics, textiles, papermaking, and liquid-repellent fibers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0156] The following examples further illustrate the present invention in detail, but should not be construed as limiting the scope of the present invention.

[0157] Hereinafter, unless otherwise specified, "parts" or "%" are parts by weight or% by weight.

[0158] The test process is as follows:

[0159] Water spray test:

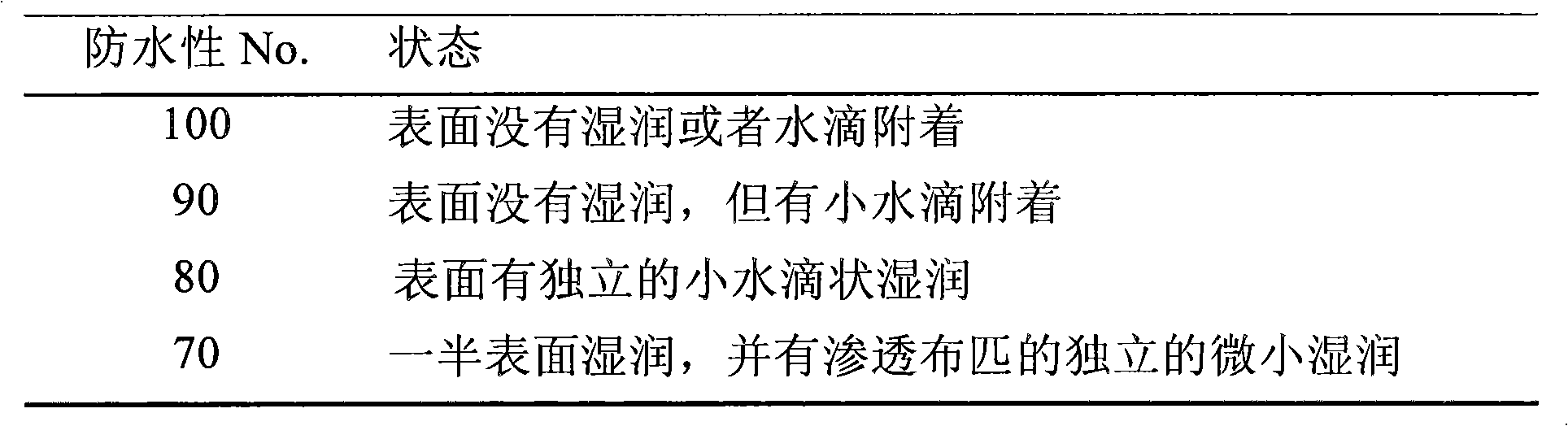

[0160] According to JIS-L-1092, carry out spray water resistance test. The water resistance No. is used to represent the spray water resistance (as shown in Table 1 below). The suffix "+" attached to the numerical value means that the performance is slightly better than the performance indicated by the numerical value.

[0161] Table 1

[0162]

[0163]

[0164] Waterproof test:

[0165] Store the treated cloth in a thermo-hygrostat at a temperature of 21°C and a humidity of 65% for at least 4 hours. The test liquids (isopropanol (IPA), water and their mixtures, as shown in Table 2) also stored at 21°C were used. The test was performed in an air-conditioned roo...

preparation example 1

[0180] CF 3 CF 2 (CF 2 CF 2 ) n CH 2 CH 2 COOCH=CH 2 (Where n is a mixture of compounds of 3, 4 and 5; the average value of n is 3.1) (160g), stearoyl acrylate (26g), cyclohexyl methacrylate (52g), glycidyl methacrylate (2.6g), N-methylolacrylamide (10.9g), 3-chloro-2-hydroxypropyl methacrylate (2.6g), octyl mercaptan (0.1g), (C 16 -C 18 ) Alkyl trimethyl ammonium chloride (20 g), lauryl dimethyl amine oxide (2 g), tripropylene glycol (42 g) and deionized water (480 g) were mixed to obtain a mixture. The mixture was heated to 60°C and emulsified with a high-pressure homogenizer. The obtained milky liquid was placed in a 300 mL flask, and replaced with nitrogen to remove dissolved oxygen. Subsequently, azobisisobutylamidine dihydrochloride (0.5 g) was charged. The polymerization was carried out while stirring at 60°C for 3 hours to produce a copolymer emulsion. The emulsion was diluted with deionized water to produce a fluorine-containing acrylic water and oil repellent (aqueo...

preparation example 2

[0183] CF 3 CF 2 (CF 2 CF 2 ) n CH 2 CH 2 COOCH=CH 2 (Where n is a mixture of compounds of 3, 4 and 5; the average value of n is 3.1) (160g), stearoyl acrylate (26g), cyclohexyl methacrylate (52g), glycidyl methacrylate (2.6g), N-methylol acrylamide (10.9g), 3-chloro-2-hydroxypropyl methacrylate (2.6g), octyl mercaptan (0.05g), (C 16 -C 18 ) Alkyl trimethyl ammonium chloride (20 g), lauryl dimethyl amine oxide (2 g), tripropylene glycol (42 g) and deionized water (480 g) were mixed to obtain a mixture. The mixture was heated to 60°C and emulsified with a high-pressure homogenizer. The obtained milky liquid was placed in a 300 mL flask, and replaced with nitrogen to remove dissolved oxygen. Subsequently, azobisisobutylamidine dihydrochloride (0.5 g) was charged. The polymerization was carried out while stirring at 60°C for 3 hours to produce a copolymer emulsion. The emulsion was diluted with deionized water to produce a fluorine-containing acrylic water and oil repellent (aqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com