Glazing coated with thin layers

A glass, thin layer technology, applied in coating, thin material handling, transportation and packaging, etc., can solve the problems of difficult silica deposition, insufficient scratch resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

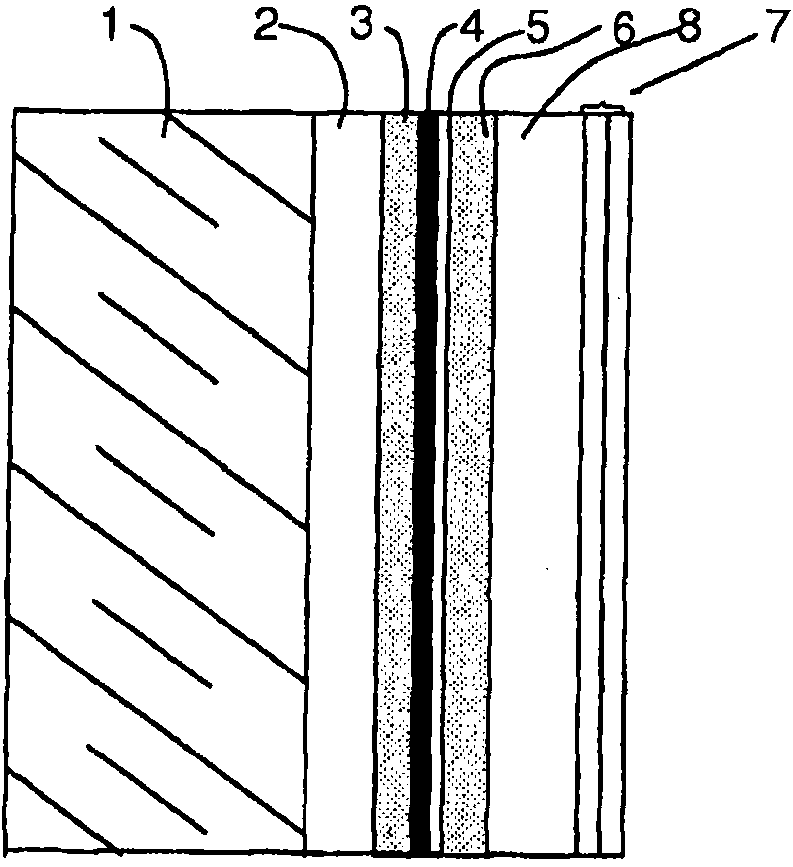

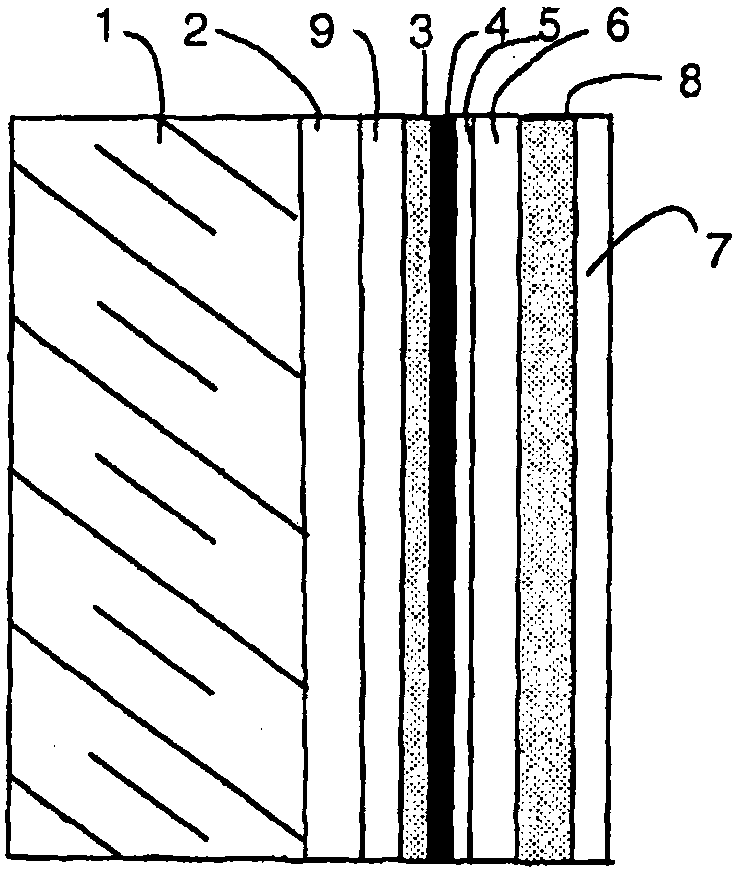

[0035] For the sake of clarity, figure 1 The glass in is presented in section without respecting the proportions of the different components. The glass sheet 1 is covered with a set of layers comprising a layer 4 based on infrared-reflecting silver. This silver layer is arranged between two sets of dielectric layers which protect it and give it good light transmission with good reflection neutrality.

[0036] The silver layer 4 is advantageously deposited on the layer 3 based on zinc oxide. Layers of zinc oxide and layers based on doped zinc oxide are known to contribute to the formation of a good interface with the silver layer without being rough. They improve the performance of the latter overall. For the same amount of silver per unit area, the conduction and thus emissivity of the layers is improved when they are deposited in this way. Only small thicknesses of zinc oxide may be involved, the thickness being no greater than 15 nm.

[0037] When the thickness of the z...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com