Electric wire slack-absorbing appratus and electric wire slack-absorbing method

A technology for absorbing equipment and electric wires, which is applied in the direction of circuits, manufacturing wiring harnesses, electrical components, etc., can solve the problems of confusing coloring patterns, difficulty in distinguishing wires, and different coloring patterns, and achieve the effects of eliminating rotation, reducing ablation, and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

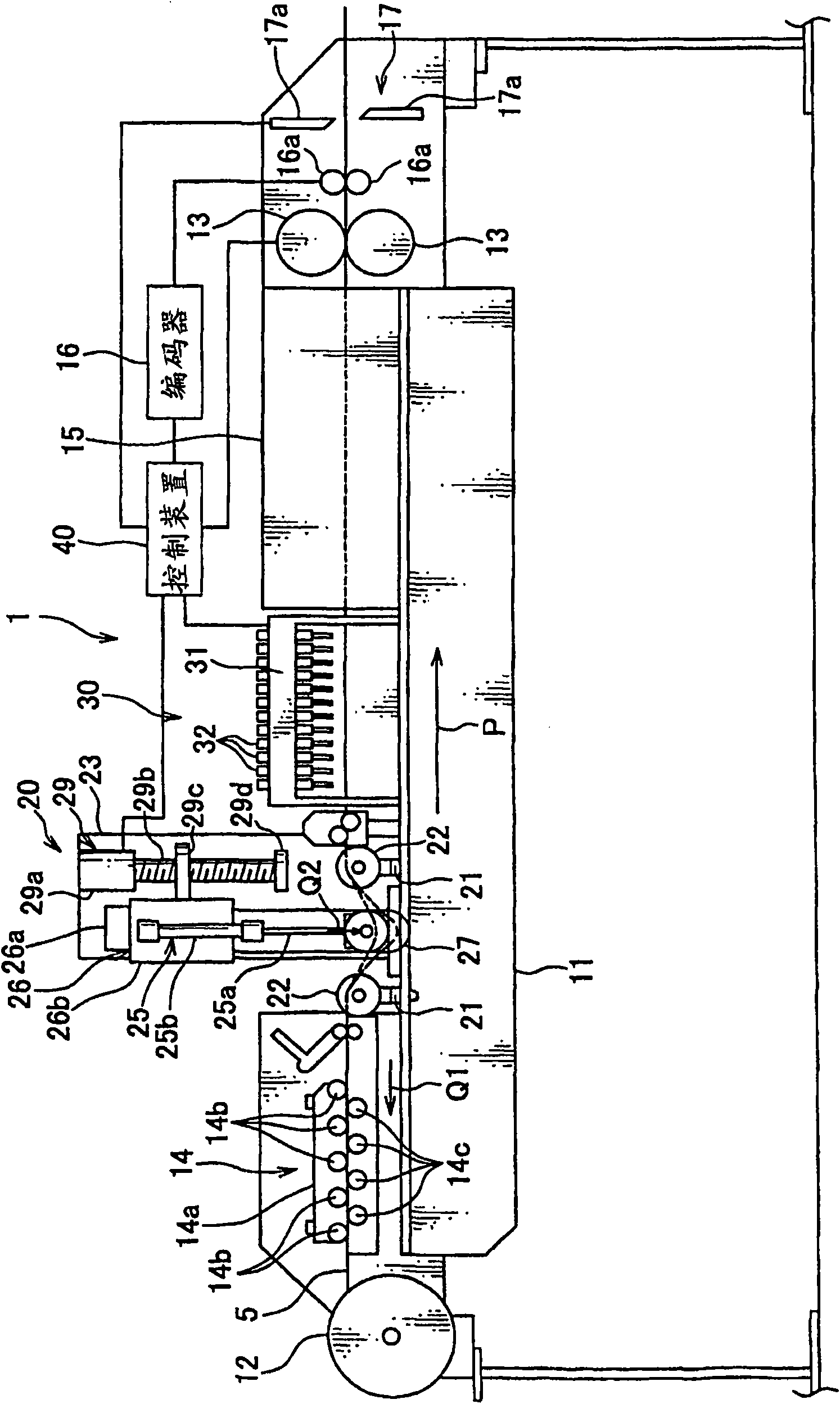

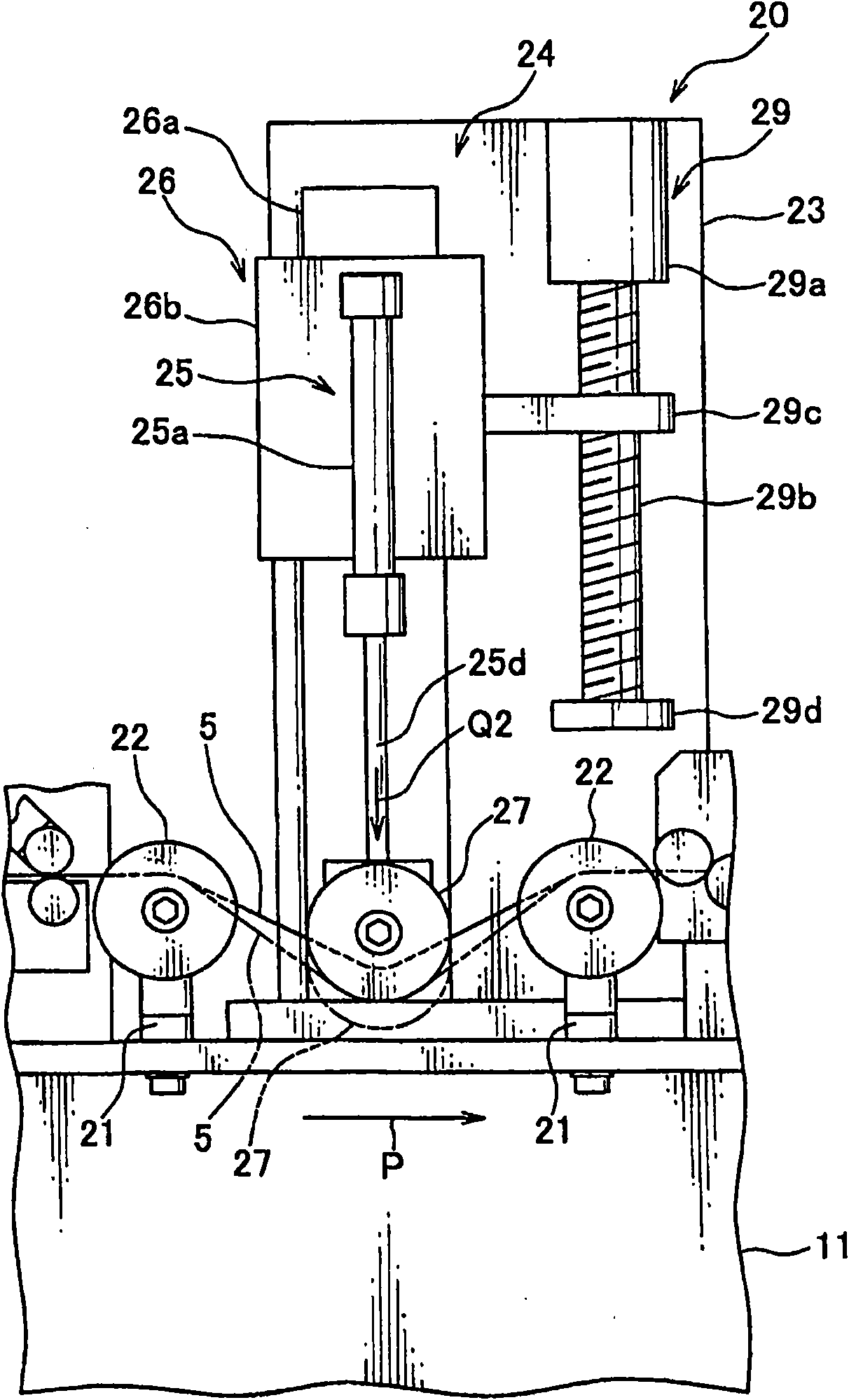

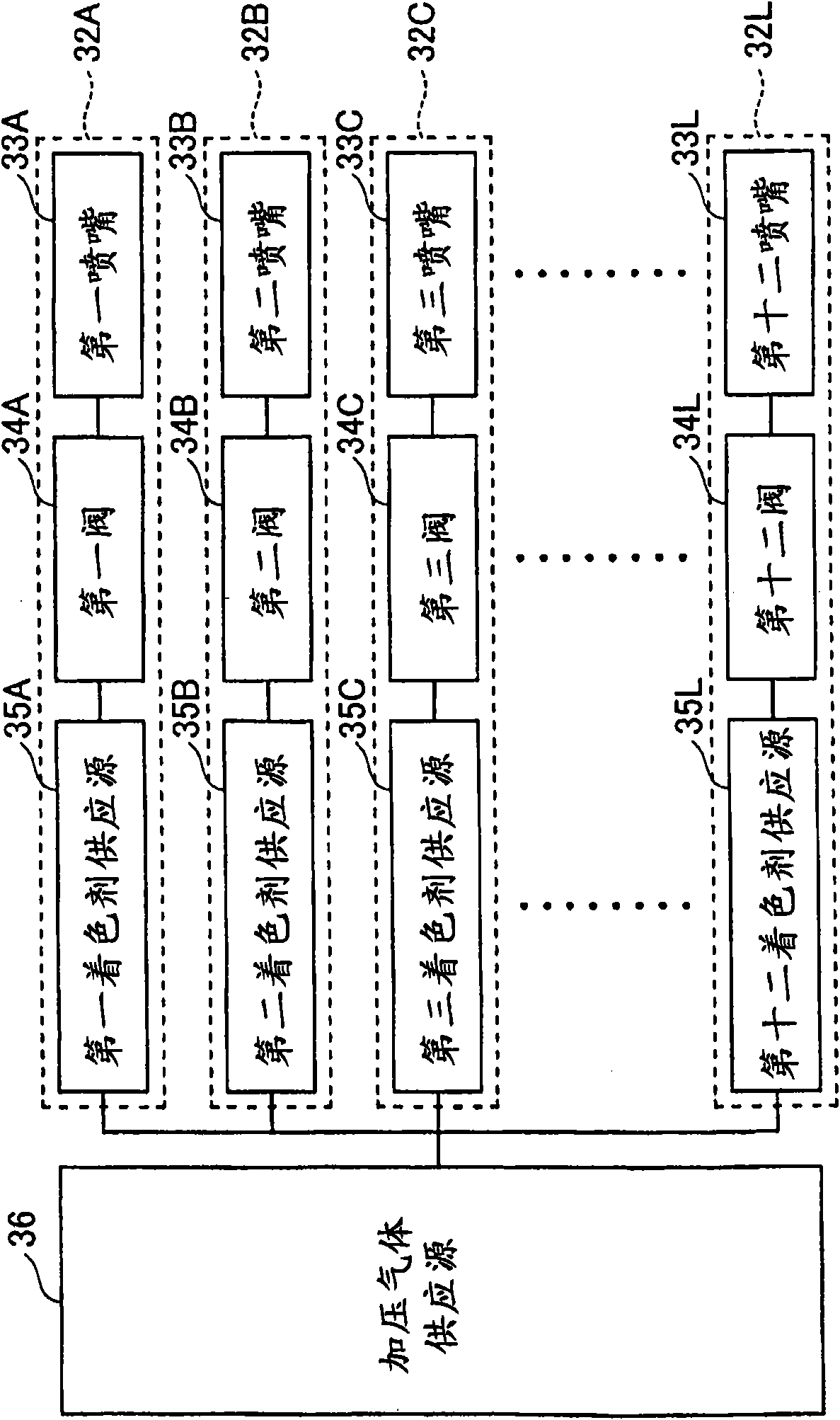

[0064] In the following, reference will be made to Figures 1 to 7 An electric wire slack absorbing device (hereinafter, slack absorbing device) according to a preferred embodiment of the present invention is explained. The slack absorbing device 1 according to a preferred embodiment of the present invention is a device that, for example, when the outer surface of a long electric wire 5 is colored and cut to a predetermined length, the electric wire 5 is drawn along the electric wire 5 The slack of the electric wire 5 is absorbed when intermittently conveyed in the longitudinal direction.

[0065] like Figure 7 As shown in , the electric wire 5 includes a conductive core wire 51 and an electrically insulating coating 52 . The core wire 51 is formed by twisting together a plurality of constituent electric wires 51a. Each constituent wire 51a is made of metal. The core wire 51 may be formed of a single constituent wire. The coating layer 52 is made of synthetic resin such ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com