Valve-free piezoelectric pump of logarithmic spiral combined tube

A valveless piezoelectric pump, logarithmic screw technology, applied in pumps, pump components, variable capacity pump components, etc., can solve the problems of large size of the confluence pipe and shunt pipe, difficult processing and manufacturing, and unfavorable micro-integration. , to achieve the effect of easy flow control, significant energy saving effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

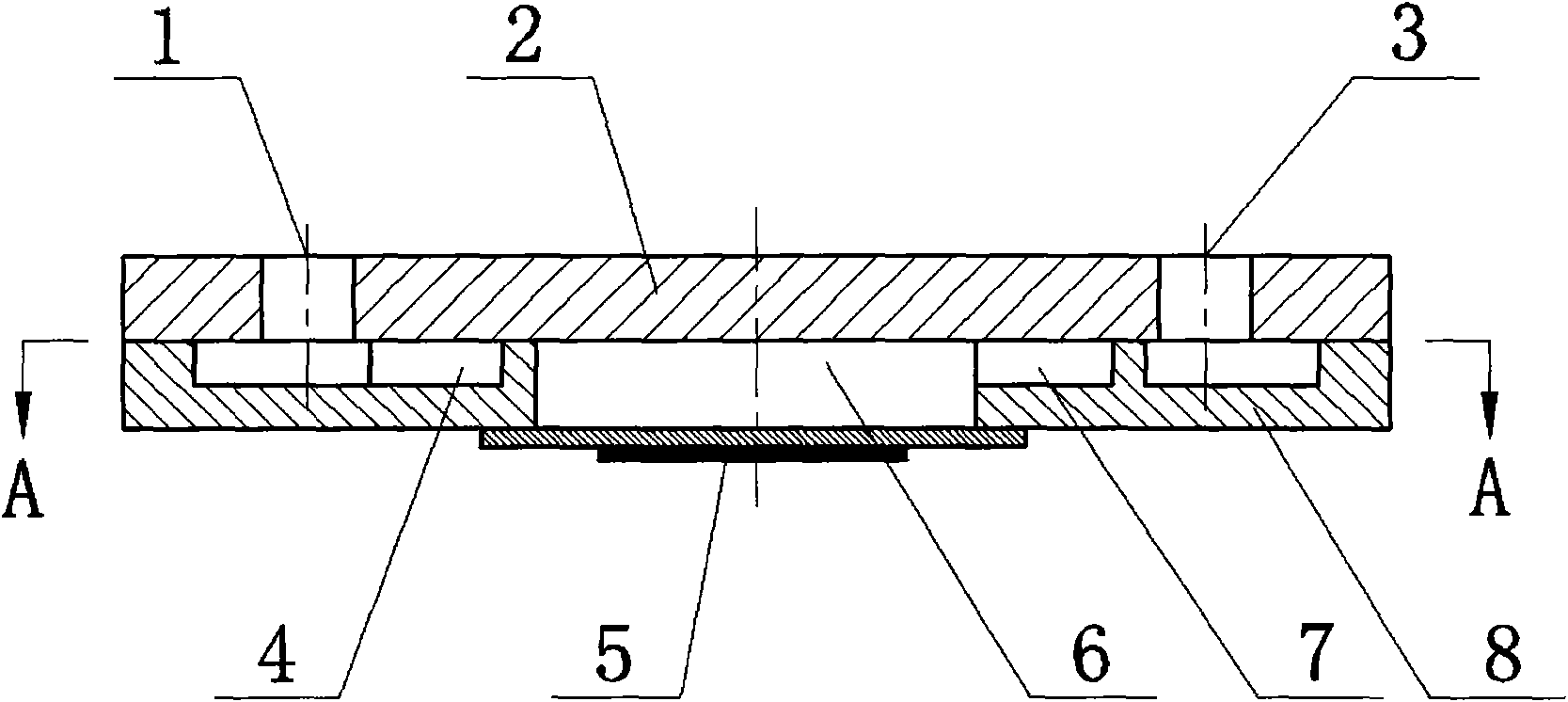

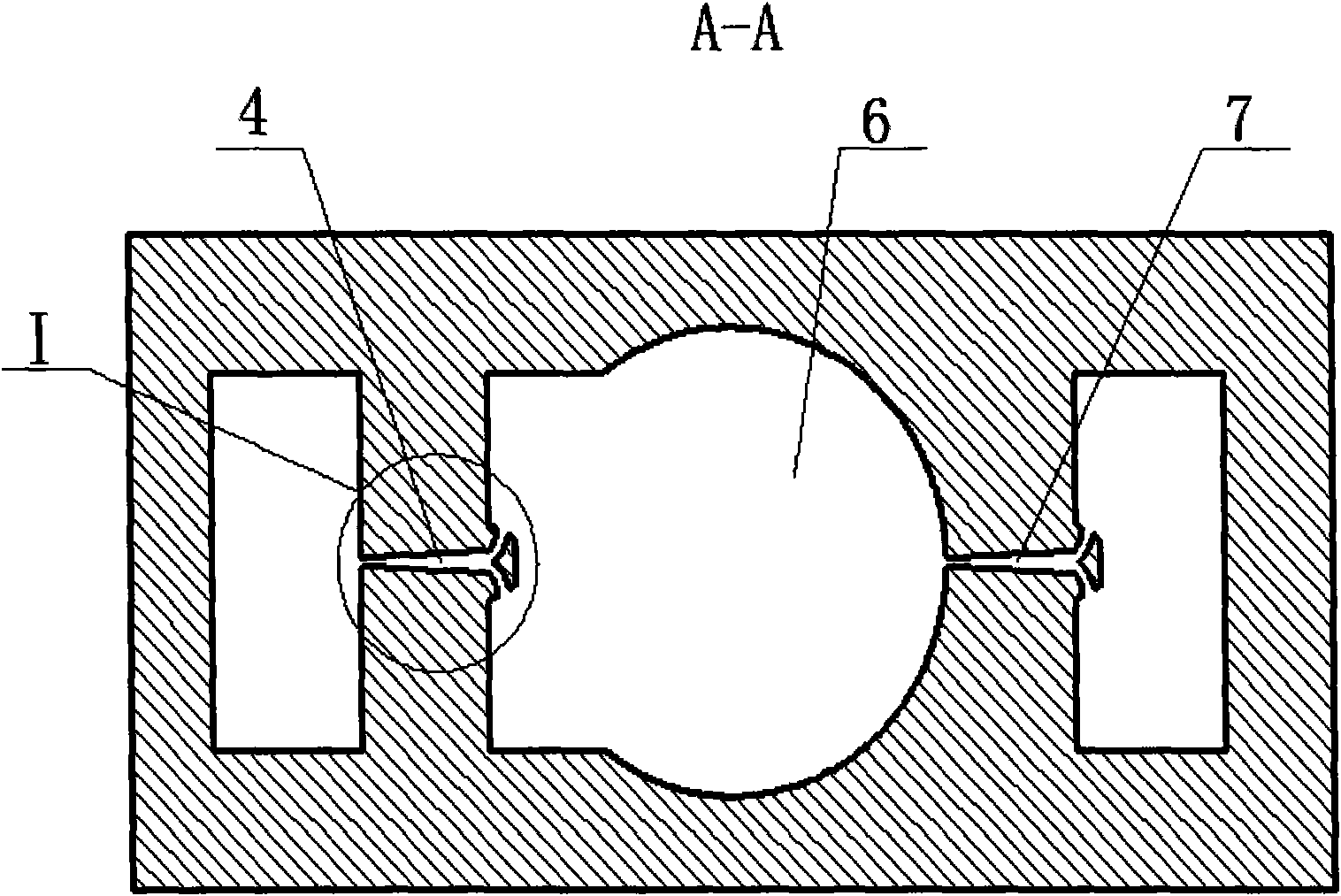

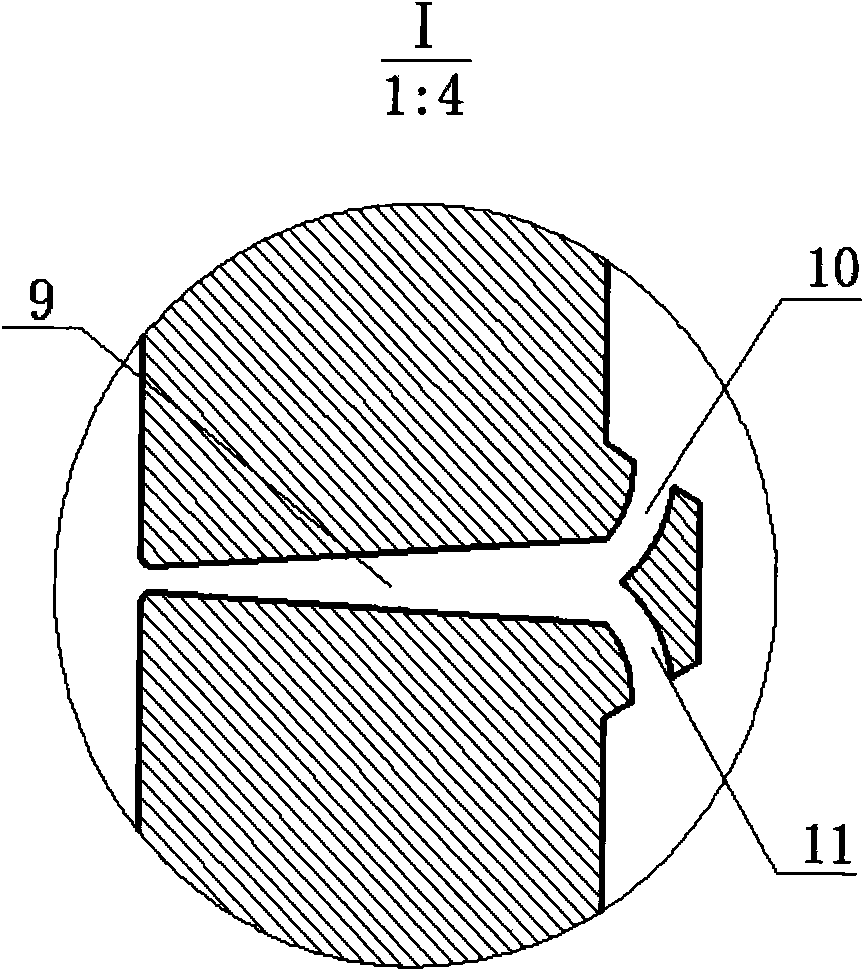

[0013] Such as Figure 1-3 , the present invention includes a pump body 8, a pump cover 2 and a piezoelectric vibrator 5, and the pump body 8 and the pump cover 2 are electrostatically bonded together. The piezoelectric vibrator 5 is fixed at the center of the lower part of the pump body 8 by an adhesive, and the pump inlet 1 and the pump outlet 3 are processed on the pump cover 2, and the pump inlet 1 and the pump outlet 3 are externally connected with an inlet pipe and an outlet pipe respectively. Two inlet flow tubes 4, outlet flow tubes 7 and a pump cavity 6 of the same structure are processed on the pump body 8 by using MEMS processing technology, wherein the pump cavity 6 is located between the inlet flow tube 4 and the outlet flow tube 7, and the inlet flow tube The flow pipe 4 and the outlet flow pipe 7 communicate with the pump chamber 6 respectively, and the three communicate with each other. The two inlet flow tubes 4 and outlet flow tubes 7 of the same structure a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tube chief | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com