Method for preparing novel fluorescent silica nanospheres

A technology of silicon dioxide and nanospheres, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of environmental damage, limited biological application of semiconductor quantum dots, and large cell damage, and achieves easy operation, wide range of luminescent wavelengths. Tuning and fluorescence stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

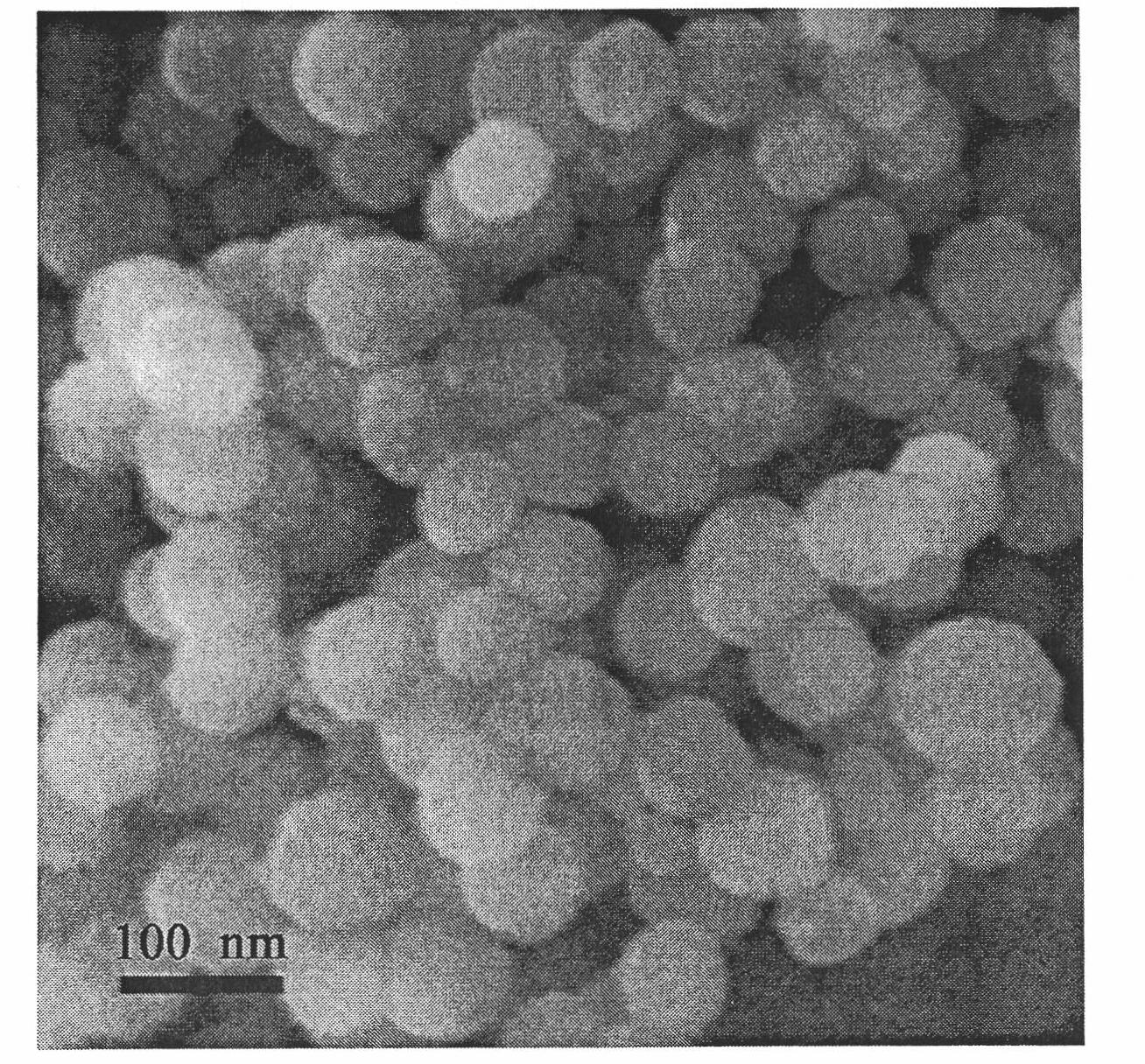

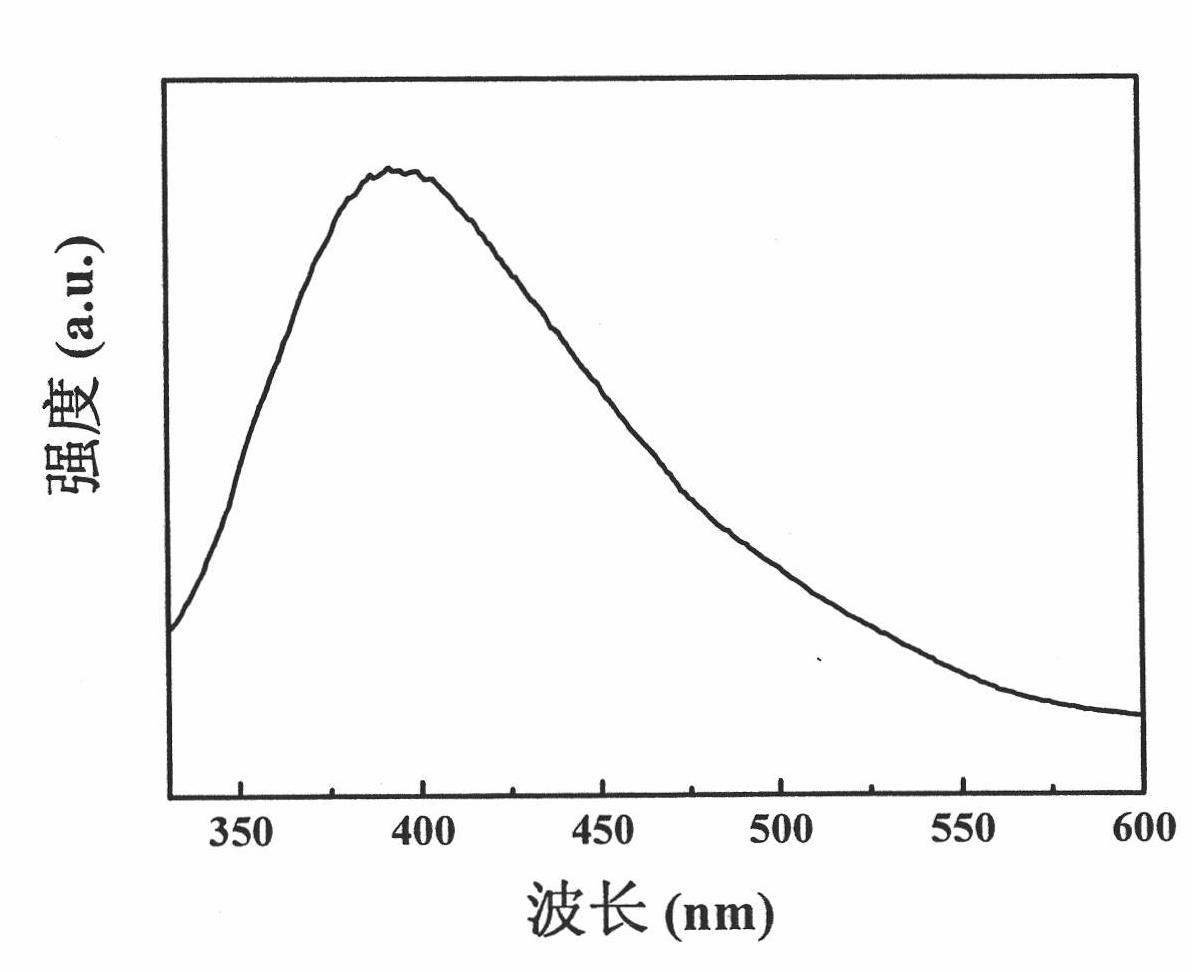

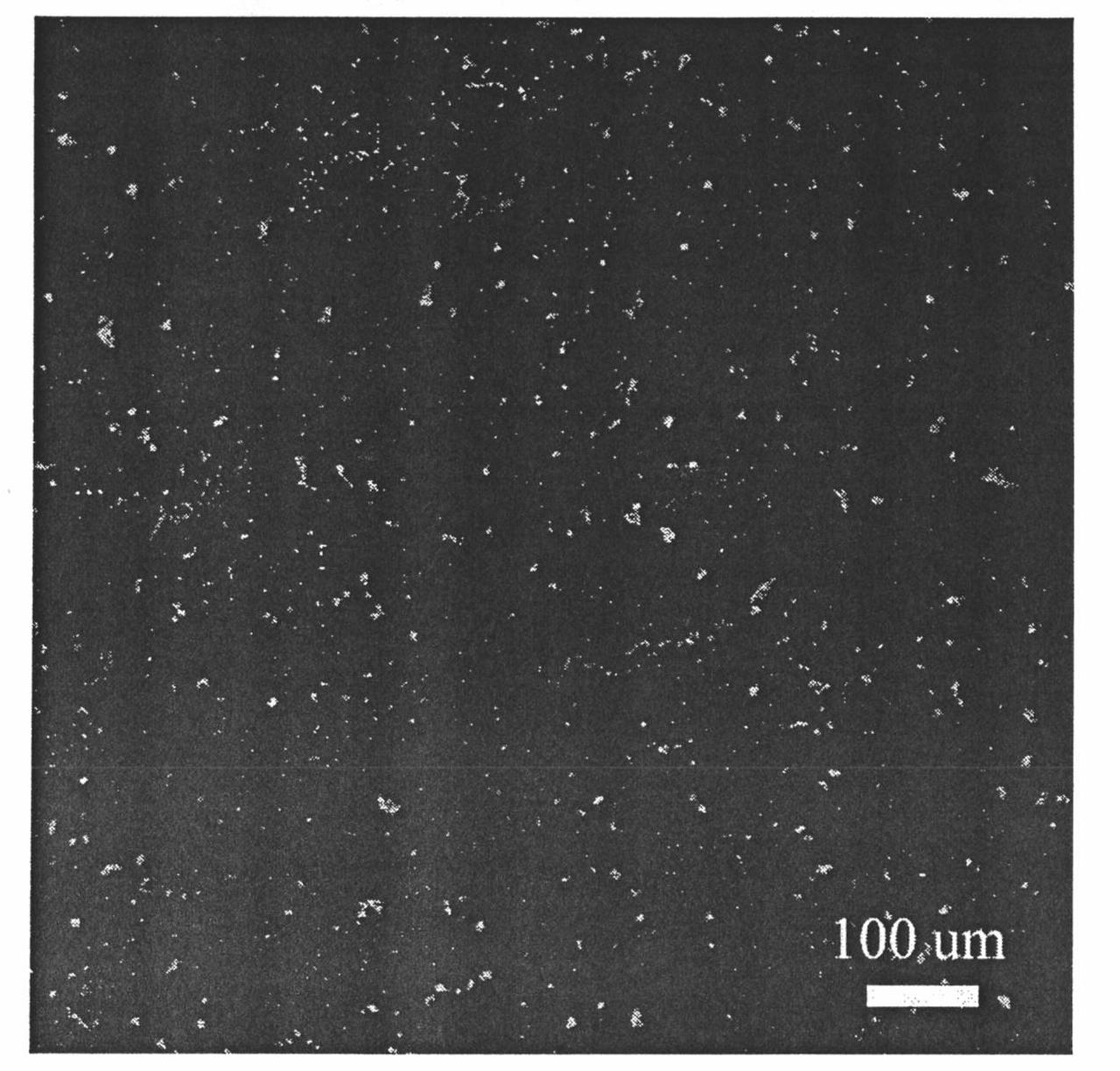

[0028] In this embodiment, the preparation steps of fluorescent silica nanospheres are as follows:

[0029] 1. Preparation of octadecylamine-modified fluorescent carbon quantum dots

[0030] (1) Preparation of fluorescent carbon quantum dots

[0031] Prepared according to the disclosed prior art, adopt 1.0g disodium ethylenediaminetetraacetic acid (EDTA-2Na), put it in a quartz boat, put it into a tube furnace and calcinate it at 380°C for 2 hours under the protection of nitrogen to obtain Fluorescent carbon quantum dots;

[0032] (2) Modification of fluorescent carbon quantum dots with octadecylamine

[0033] Dissolve 0.5g of fluorescent carbon quantum dots in 30mL of water, ultrasonically disperse, and then centrifuge, take 20mL of its supernatant, adjust the pH value of the solution to 5.5 with acetic acid; then add 0.5g of octadecylamine and 20mL of supernatant to the supernatant Toluene, mixed evenly; then pour the above mixed solution into the reaction kettle, and rea...

Embodiment 2

[0042] The implementation process steps are all the same as in Example 1 except for the following differences.

[0043] Measure 40mL of ethanol (CH 3 CH 2 OH) into the solution and mix well, then slowly add 1mL ammonia water (NH4 OH), 1 mL tetraethyl orthosilicate (TEOS), and stirred at 40°C for 1 hour.

[0044] In step (3), 1 mL of TEOS and 0.5 g of cetyltrimethylammonium bromide (CTAB) were gradually and slowly added to the solution, and after slow stirring for 1 hour, the lower layer was centrifuged with a high-speed centrifuge to remove the precipitate.

[0045] The result is basically similar to Example 1, the difference is that fluorescent SiO 2 The shell portion of the nanospheres is slightly thinner than Example 1 in thickness.

Embodiment 3

[0047] The implementation process steps are all the same as in Example 1 except for the following differences.

[0048] In step (2), measure 40 mL of ethanol (CH 3 CH 2 OH) into the solution and mix well, then slowly add 1mL ammonia water (NH 4 OH), 4 mL tetraethyl orthosilicate (TEOS), and stirred at 40°C for 12 h.

[0049] In step (3), 4 mL of TEOS and 1.5 g of cetyltrimethylammonium bromide (CTAB) were gradually and slowly added to the solution, and after the reaction was stirred slowly for 12 hours, the lower layer was centrifuged with a high-speed centrifuge to remove the precipitate.

[0050] The result is similar to Example 1, the difference is that fluorescent SiO 2 Both the core part and the shell part of the nanosphere are slightly thicker than that of Example 1, and the fluorescence performance is slightly weakened.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com