Antifogging agent for glasses and preparation method thereof

An anti-fog agent and glasses technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of inability to achieve anti-fog effect, poor anti-fog effect, etc., and achieve extended anti-fog time, easy portability, and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

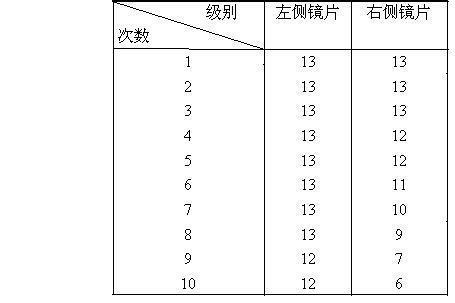

Image

Examples

Embodiment 1

[0021] Prepare 100kg glasses antifogging agent, the consumption of each raw material is as follows:

[0022] Methyl trifluoropropyl silicone oil 2kg,

[0023] Isopropanol 5kg,

[0024] 1,5 pentanediol 2kg,

[0025] Sodium dodecylbenzenesulfonate 2kg,

[0026] The balance is water.

[0027] The preparation method is as follows:

[0028] (1) Add 2kg of sodium dodecylbenzenesulfonate to 89kg of water and stir to obtain a uniform liquid;

[0029] (2) Slowly add 2kg of methyl trifluoropropyl silicone oil to the liquid in step (1), and stir to obtain a uniform liquid;

[0030] (3) Add 5kg of isopropanol and 2kg of 1,5-pentanediol to the liquid obtained in step (2), and stir evenly to obtain an antifogging agent for glasses.

Embodiment 2

[0032] Prepare 100kg glasses antifogging agent, the consumption of each raw material is as follows:

[0033] Methyl trifluoropropyl silicone oil 5kg,

[0034] Isopropanol 8kg,

[0035] 1,5 pentanediol 5kg,

[0036] Sodium dodecylbenzenesulfonate 5kg,

[0037] The balance is water.

[0038] The preparation method is as follows:

[0039] (1) Add 5kg of sodium dodecylbenzenesulfonate to 77kg of water, and stir to obtain a uniform liquid;

[0040] (2) Slowly add 5kg of methyl trifluoropropyl silicone oil to the liquid in step (1), and stir to obtain a uniform liquid;

[0041] (3) Add 8kg of isopropanol and 5kg of 1,5-pentanediol to the liquid obtained in step (2), and stir evenly.

[0042] The anti-fogging agent for glasses of the present invention can be filled in a small watering can and sprayed for use, and then the lens is wiped evenly with a clean cloth, and dried; it can also be used as an anti-fogging agent after soaking a cloth or paper towel with strong adsorpti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com