Electromobile energy feedback braking and ABS (Anti-skid Brake System) integration hydraulic pressure unit

A technology of energy feedback and electric vehicles, applied in the direction of hydraulic brake transmission, etc., can solve the problems of low braking energy recovery rate, large braking torque fluctuation, high machining accuracy, etc., and achieve simple structure, prolong service life, and easy batch production The effect of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

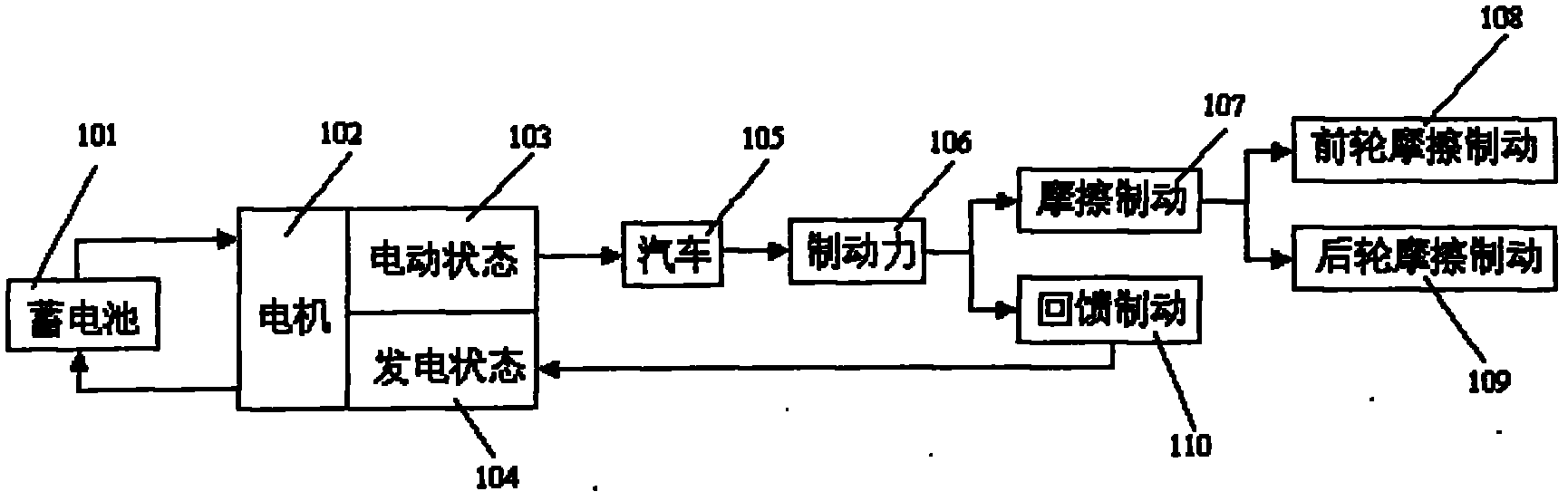

[0019] Such as figure 1 Shown is a schematic diagram of the energy transmission of the electric vehicle of the present invention. The energy of the storage battery 101 drives the car 105 through the electric state 103 of the motor 102. When the car needs to slow down or stop, a braking force 106 is required to act. The braking force 106 is generated by friction braking 107, regenerative braking 110 or both , wherein, the friction brake 107 is dissipated in the form of brake friction heat by the front wheel friction brake 108 and the rear wheel friction brake 109, and the braking energy cannot be utilized; the regenerative brake 110 is driven by the car to rotate the motor 102 to work in the power generation state 104 , the motor 102 generates electric energy and stores it in the storage battery 101 . figure 1 Friction braking 107 and regenera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com