Continuous oxidation reaction kettle for trimethyl benzene

A technology of oxidation reaction and metatrimethylbenzene, which is applied in chemical/physical/physical chemical fixed reactors, organic chemistry, chemical instruments and methods, etc., can solve problems such as short service life, large material loss, and long process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

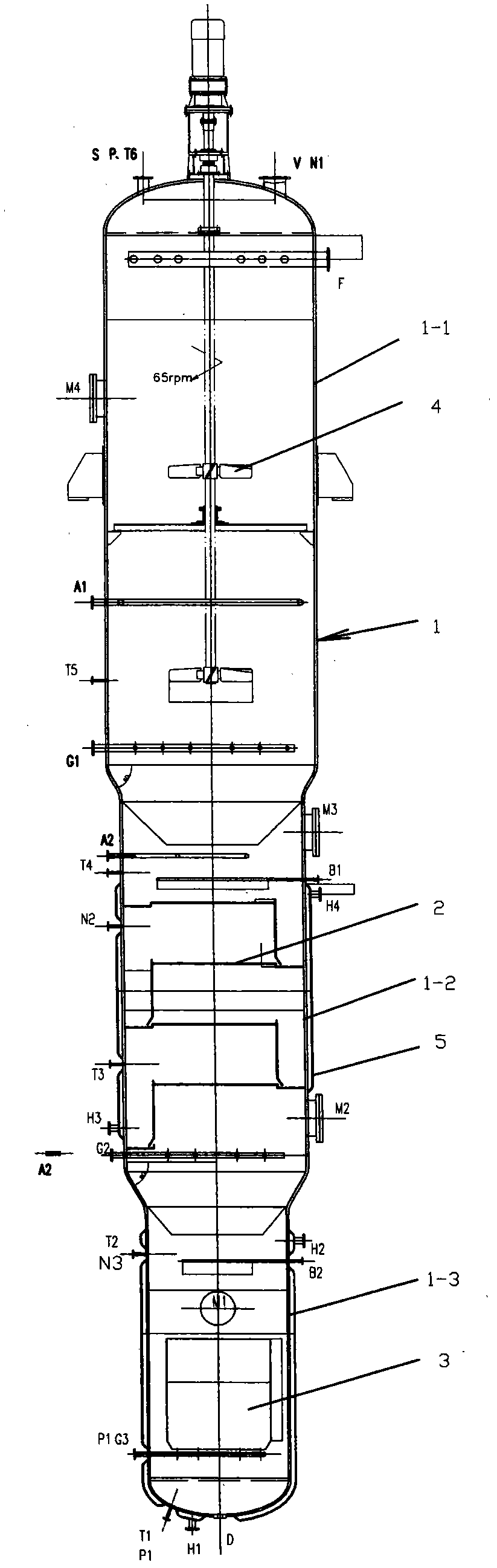

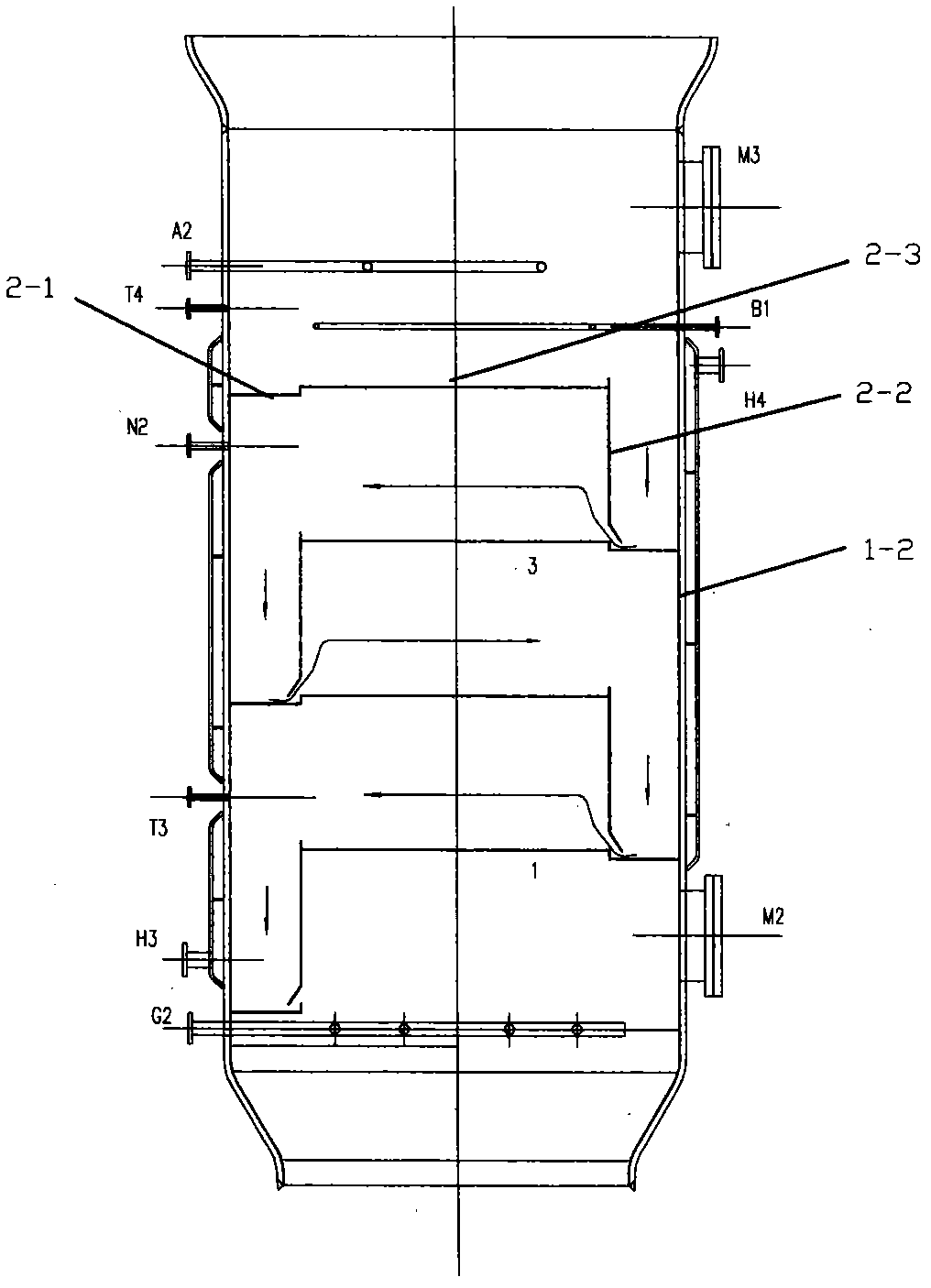

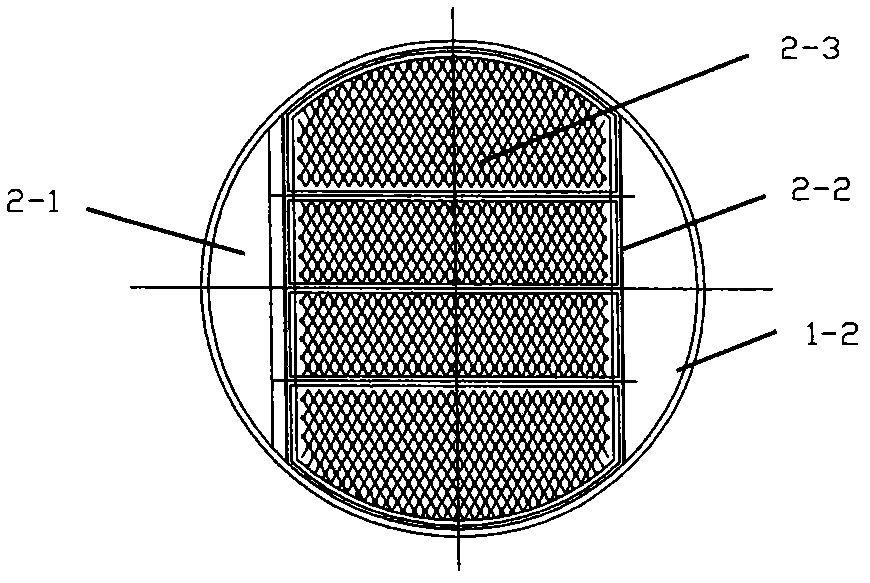

[0018] The continuous oxidation reaction kettle of trimethylbenzene of the present embodiment is as figure 1 and Figure 4 As shown, the tank-shaped reactor body 1 is divided into upper, middle and lower sections 1-1, 1-2, and 1-3, which are reduced from top to bottom, and each section is connected by a transition cone. The upper part of the kettle body is equipped with a stirring device 4 driven by an external vertical motor, and the top has a gas phase outlet V, and a measurement and explosion-proof port. The lower section 1-3 and the middle section 1-2 of the kettle body have a sandwich-type heat conduction oil heating device 5 (the specific structure of which is combined below Figure 6 Detail), the bottom has a discharge port D, and a heat transfer oil inlet H1 and a temperature measuring port T1. The kettle body has secondary feed pipes distributed up and down. The first-stage feed pipe is located on the upper section of the kettle body and is input from the feed inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com