Method for follow-up testing of temperature of steel billet in furnace

A billet and temperature recording technology, applied to thermometers, thermometers with directly heat-sensitive electric/magnetic elements, measuring devices, etc., can solve problems affecting temperature measurement accuracy, thermal stress deformation, shedding, etc., to improve accuracy and reliability, accurate and reliable measurement, small dynamic error effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

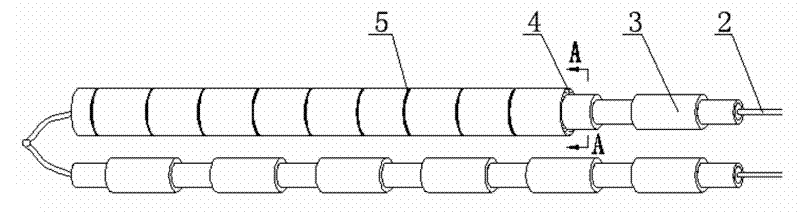

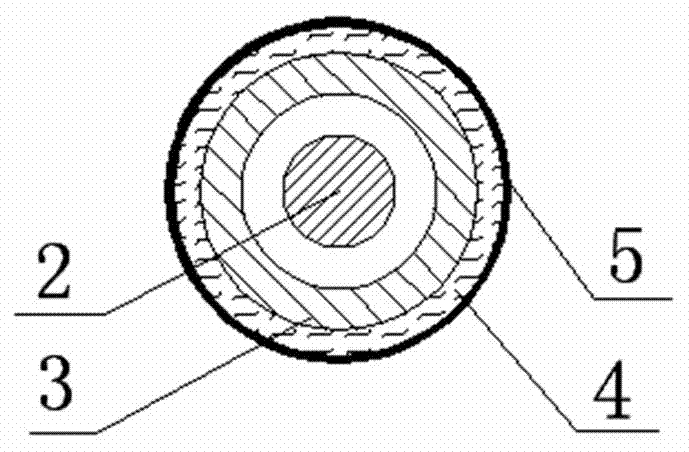

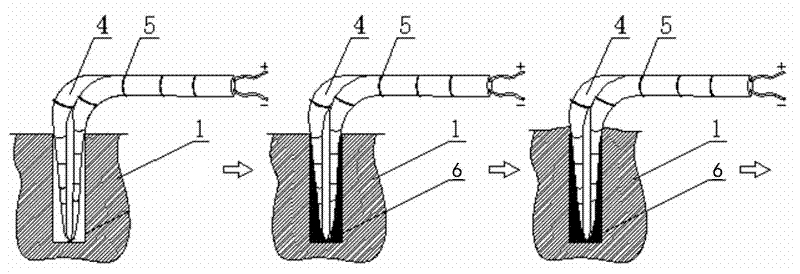

[0027] The embodiment of the method for tracking the temperature of steel slabs in the furnace according to the present invention includes the steps of preliminary preparation and the steps of tracking and testing in the furnace.

[0028] The pre-preparation steps are as follows:

[0029] Step (1), the step of drilling a hole on the billet to be tested; the size of the hole is 0.5-1 mm larger than the diameter of the thermocouple.

[0030] Step (2), insert the hot end of the thermocouple into the hole drilled in step (1), such as image 3 As shown, and make the hot end of the thermocouple contact with the bottom of the hole; use iron powder 6 of the same material as the billet to be tested to fill and compact the empty space in the hole.

[0031] Step (3), hammering the top edge of the hole with a steel chisel to deform the top edge of the hole toward the center of the hole so as to wrap the iron powder 6 outside the thermocouple and inside the hole.

[0032] The thermocoupl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com