Conveyer belt water cleaning system of belt type conveyer

A belt conveyor and conveyor belt technology, applied in the field of water cleaning systems, can solve the problems of increasing equipment maintenance and cleaning environment costs, being unable to be cleaned and sticking, reducing the operating efficiency of conveyors, etc., to improve operating efficiency and Long service life, simple structure, good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

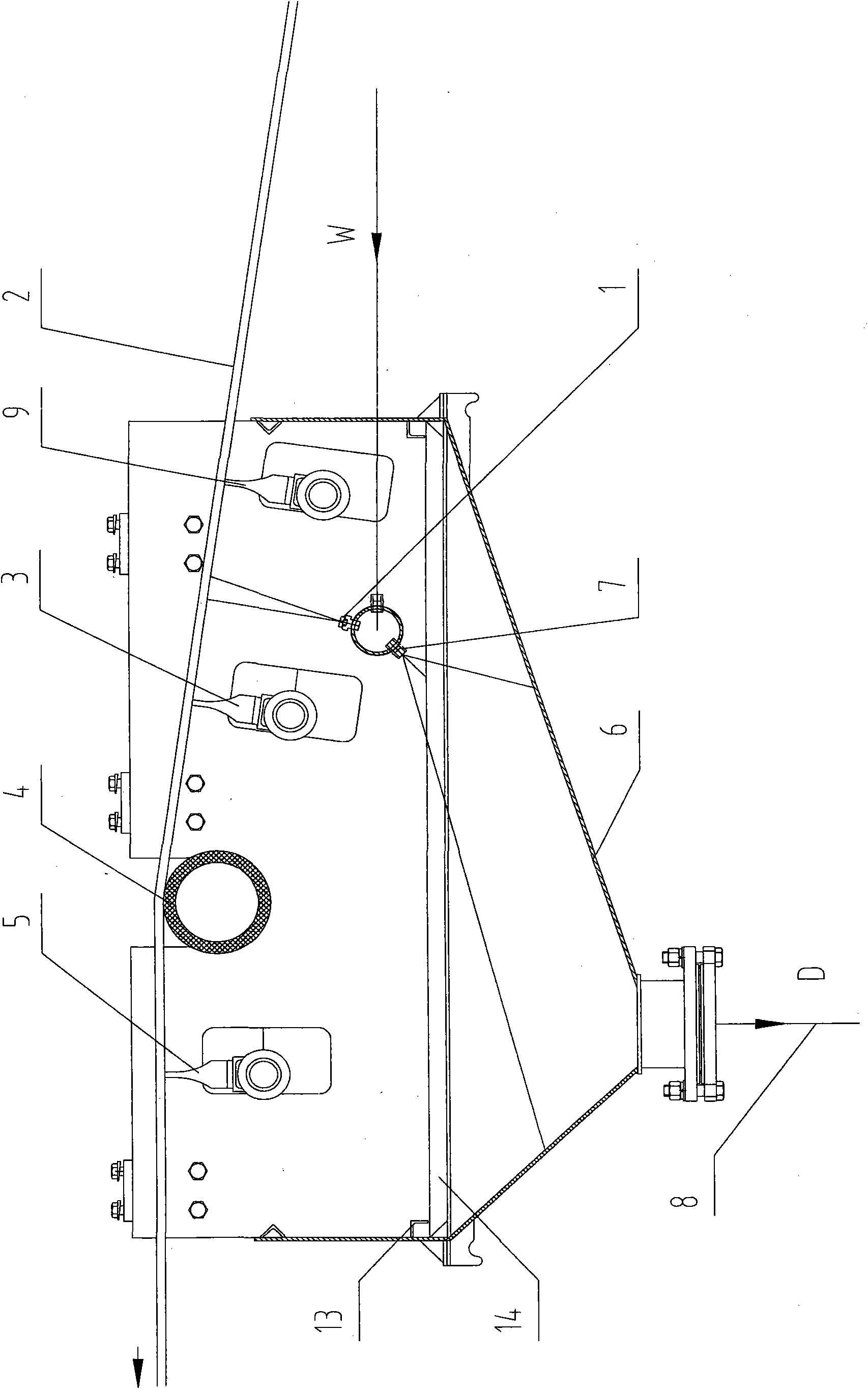

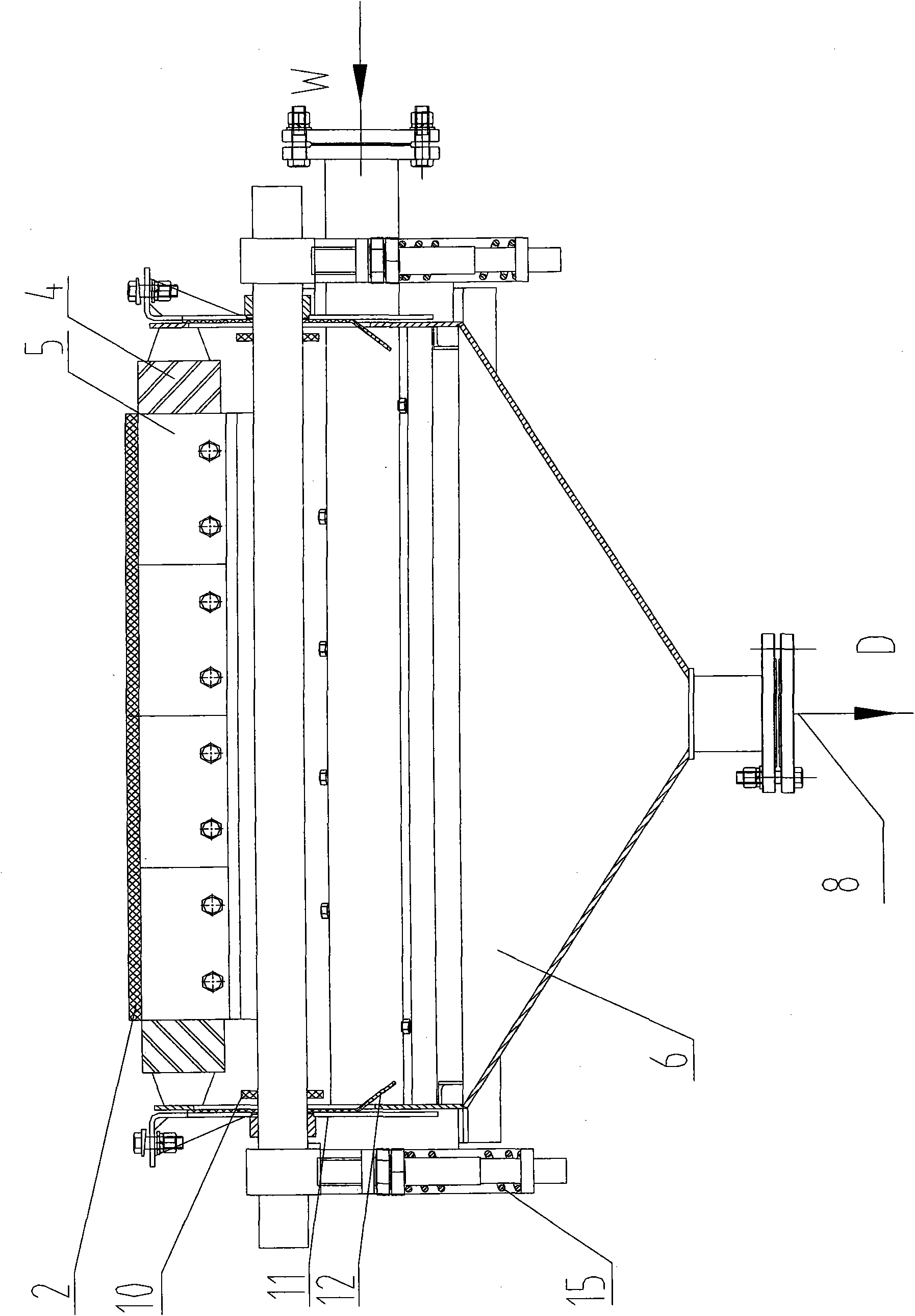

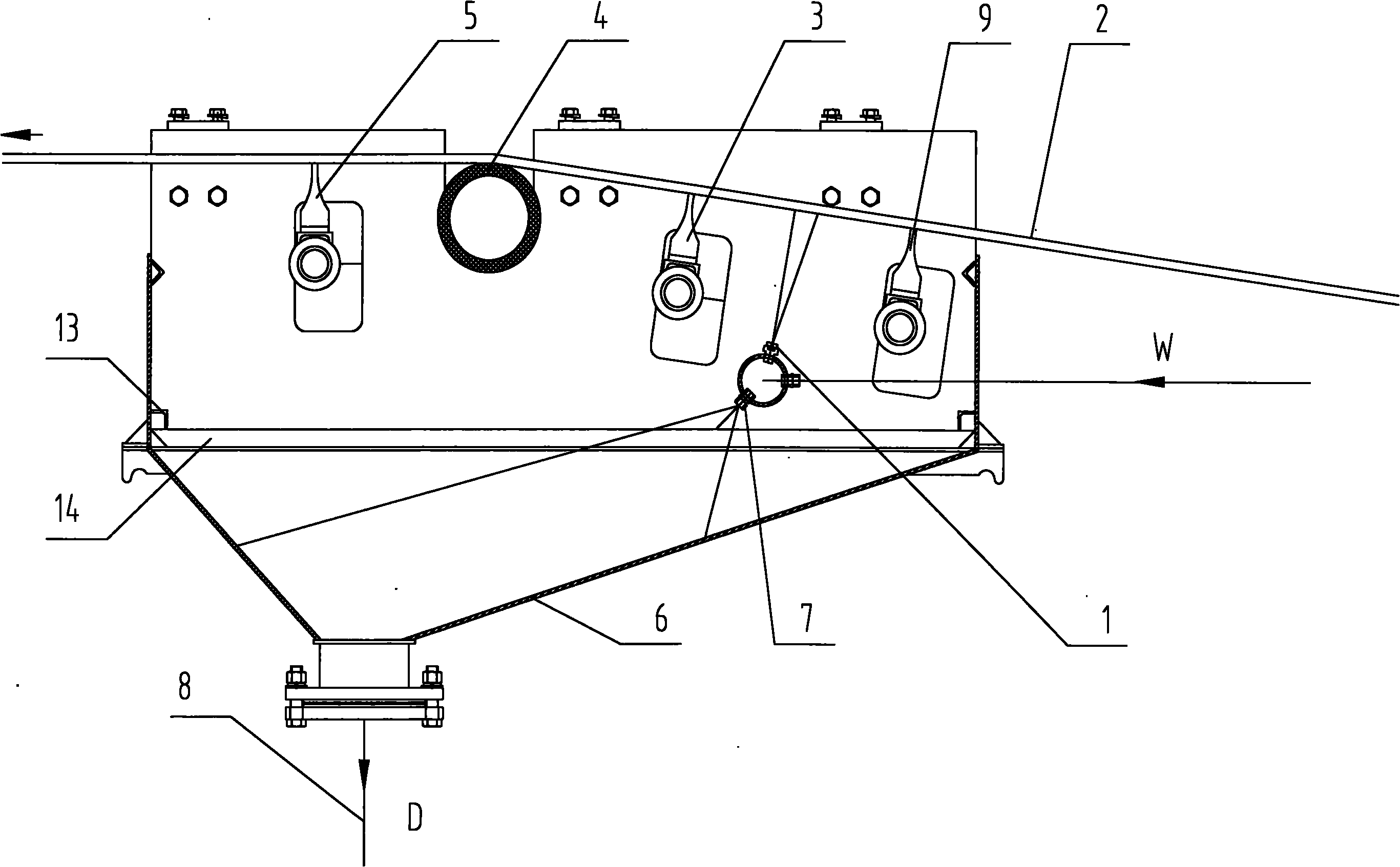

[0010] Referring to the accompanying drawings, a conveyor belt water cleaning system for a belt conveyor, the whole device consists of a fan nozzle 1, a conveyor belt surface 2, a first cleaner 3, a roller 4, a second cleaner 5, a collector 6, and a rectangular nozzle 7 , the sewer pipe 8, the third cleaning device 9, the water retaining rubber ring 10, the water retaining plate 11, the water retaining rubber plate 12, the parts 13 welded on the side wall plate, the chamfered ends welded on the horizontal pull plate Component 14 and spring structure 15, the water entering the upper water pipe is sprayed on the conveyor belt surface 2 at a fixed angle, fixed flow rate, and fixed pressure from the fan-shaped nozzle 1 to dissolve the adhesive on the conveyor belt surface , stripping, clearing, the spring structure 15 makes the first cleaning device 3 contact the conveyor belt surface 2 with a certain pressure, scrape off the remaining dissolved adhesives and water, and the redirec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com