Instrument step motor with large rotor and low speed ratio

A technology of instruments and magnet rotors, applied in electrical components, electromechanical devices, etc., can solve the problems of large reduction ratio, difficult assembly, and difficult gear processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

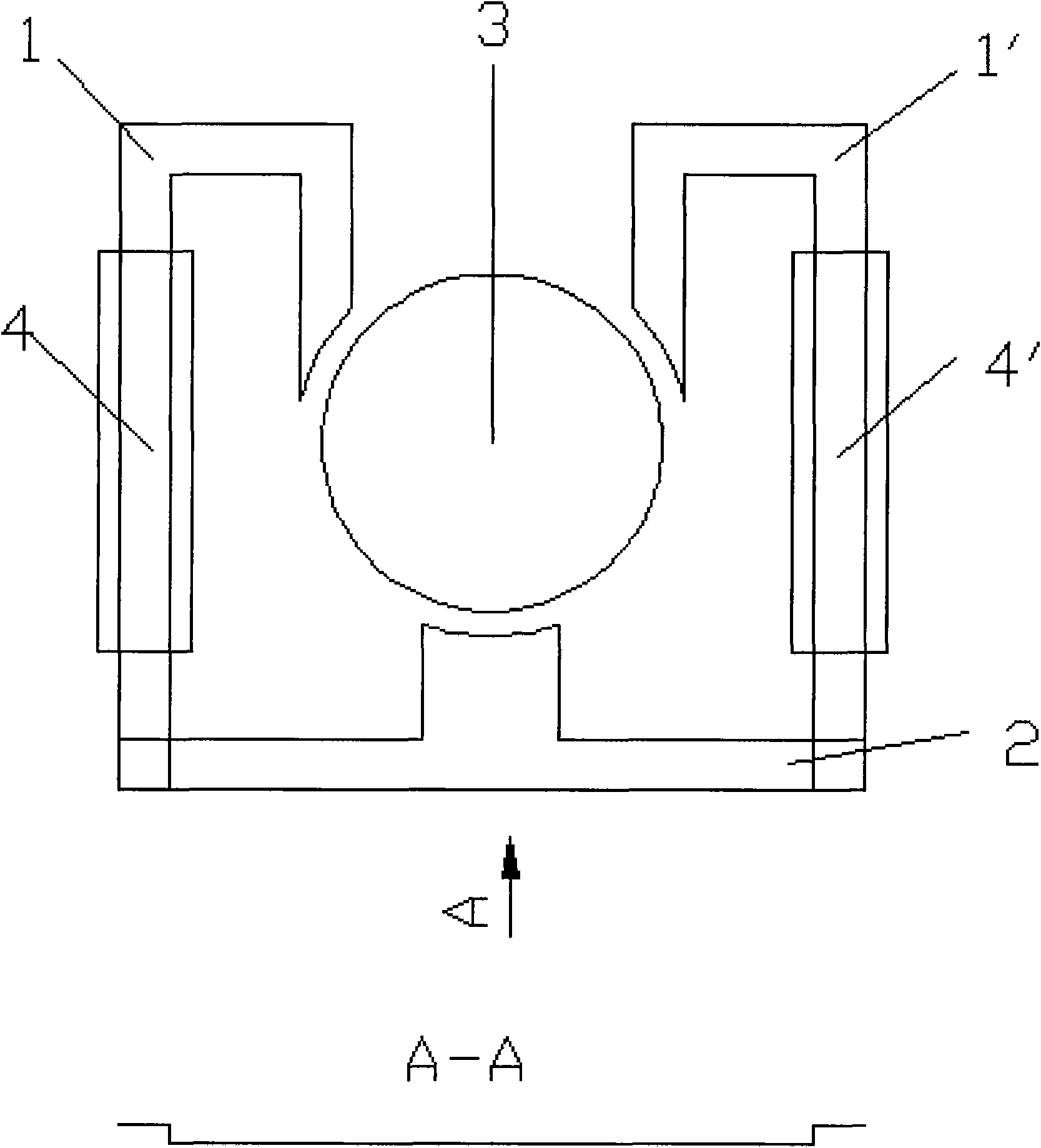

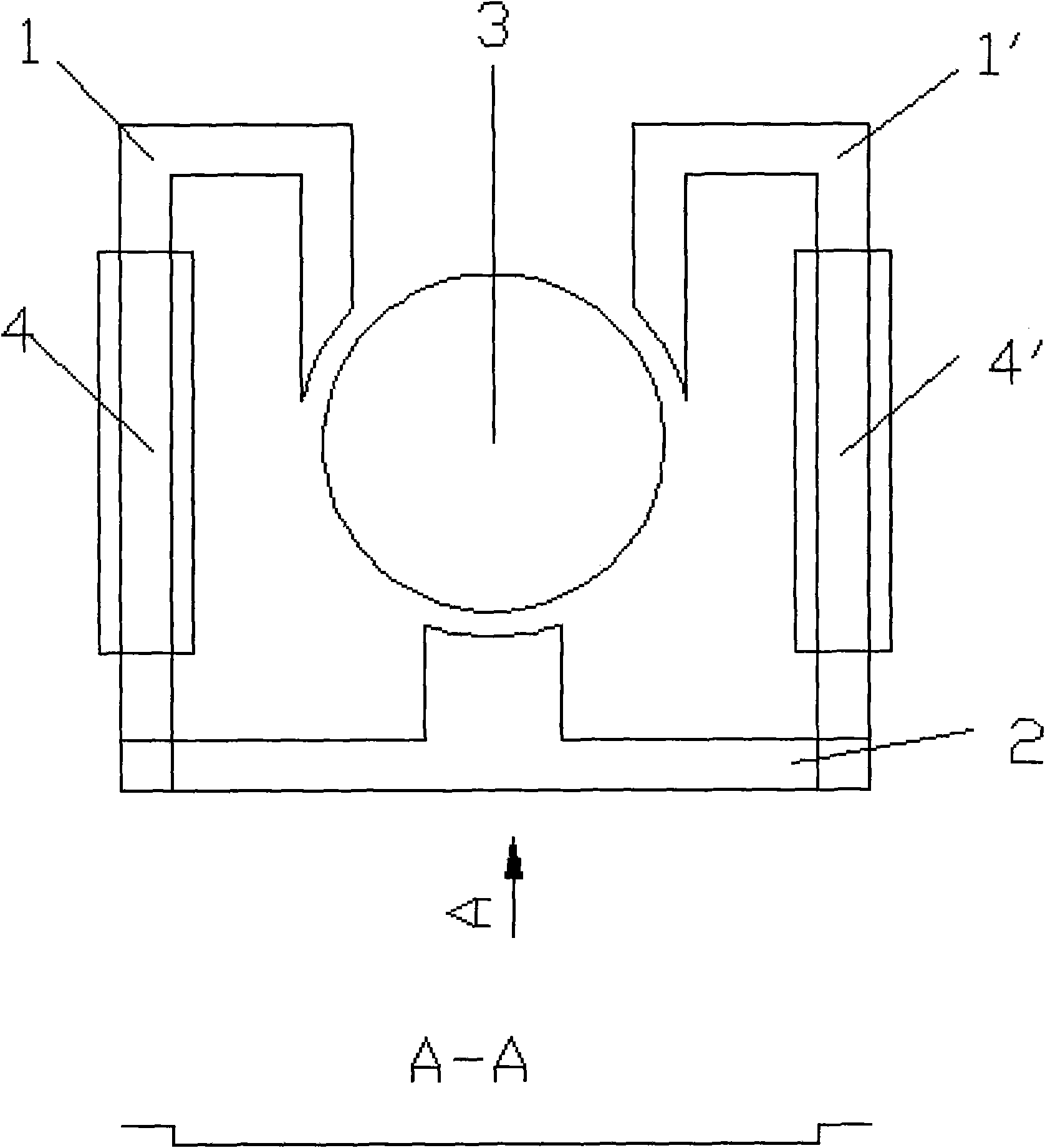

[0009] There are three stator slices: the first stator slice 1, the second stator slice 1`, and the third stator slice 2. One end surface of each stator piece is used as a magnetic pole surface, which is equally divided into 120° and distributed on the circumference. The other end of the first stator piece 1 passes through the stator coil 4 and is pressed against the third stator piece 2; the other end of the second stator piece 1` passes through the stator coil 4` and is pressed against the third stator piece 2, That is, the other end of the third stator piece 2 is separated by 180°, and is pressed against the first and second parts protruding from the stator coil. The third stator lamination is creased at the lap, see A-A. A magnet rotor 3 with a diameter of 5 to 8 mm is installed in the circumference, and the magnet rotor is radially filled with four pairs of magnetic poles.

[0010] When the external driving current enters the coil 4 and the coil 4 ′, the direction of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com