Anode aluminum alloy nut cap for cylindrical lithium ion battery

A lithium-ion battery, cylindrical technology, applied to battery pack parts, circuits, electrical components, etc., can solve problems such as increased internal resistance of welding points, low bonding strength of spot welding, and affecting battery pack service life, etc., to achieve easy mechanical Improvement of sealing, series and parallel reliability, and effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

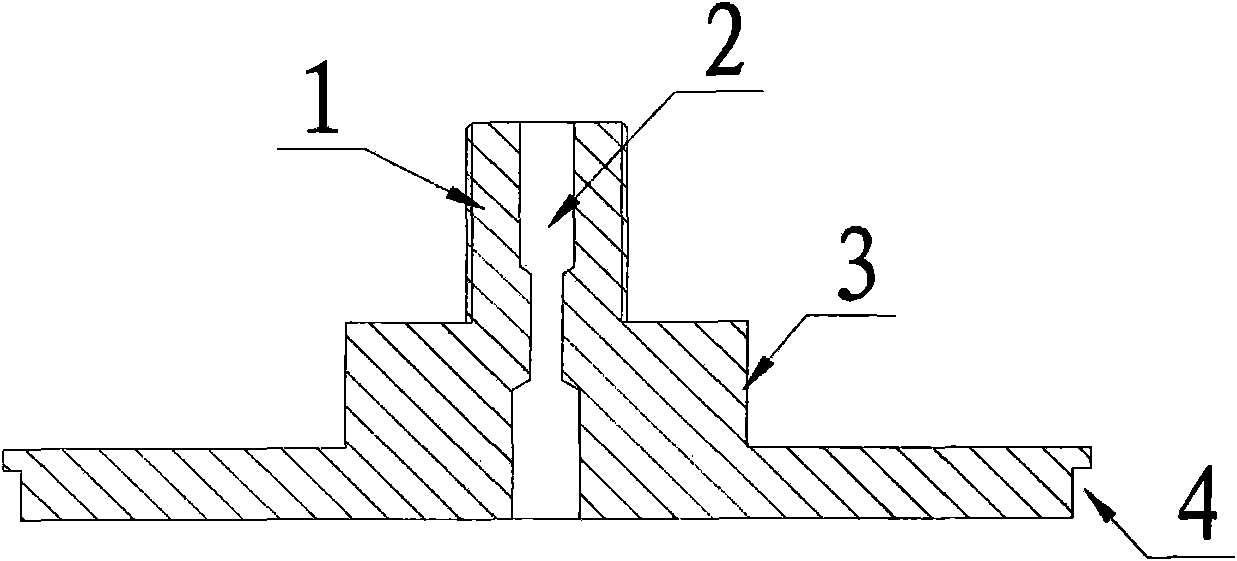

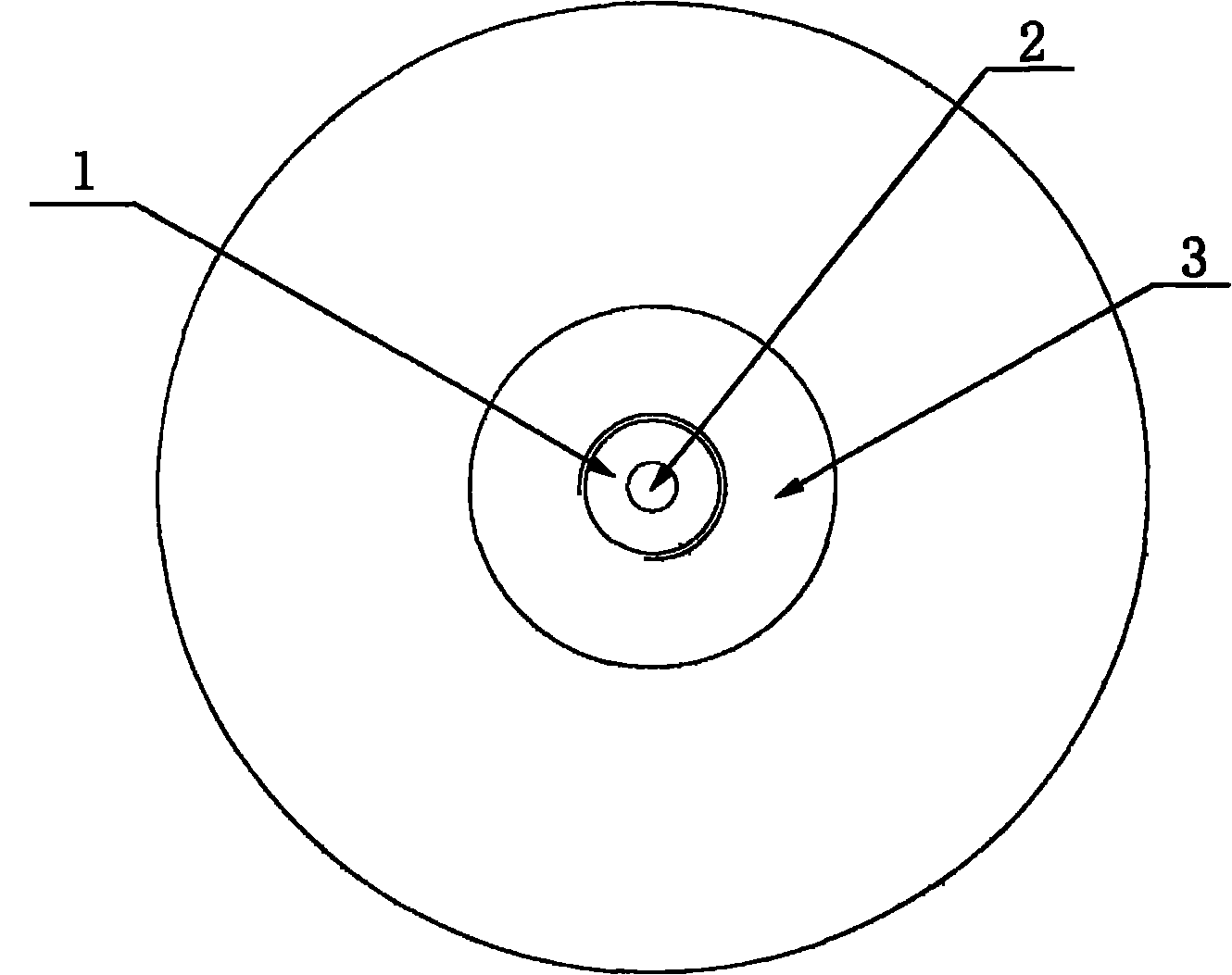

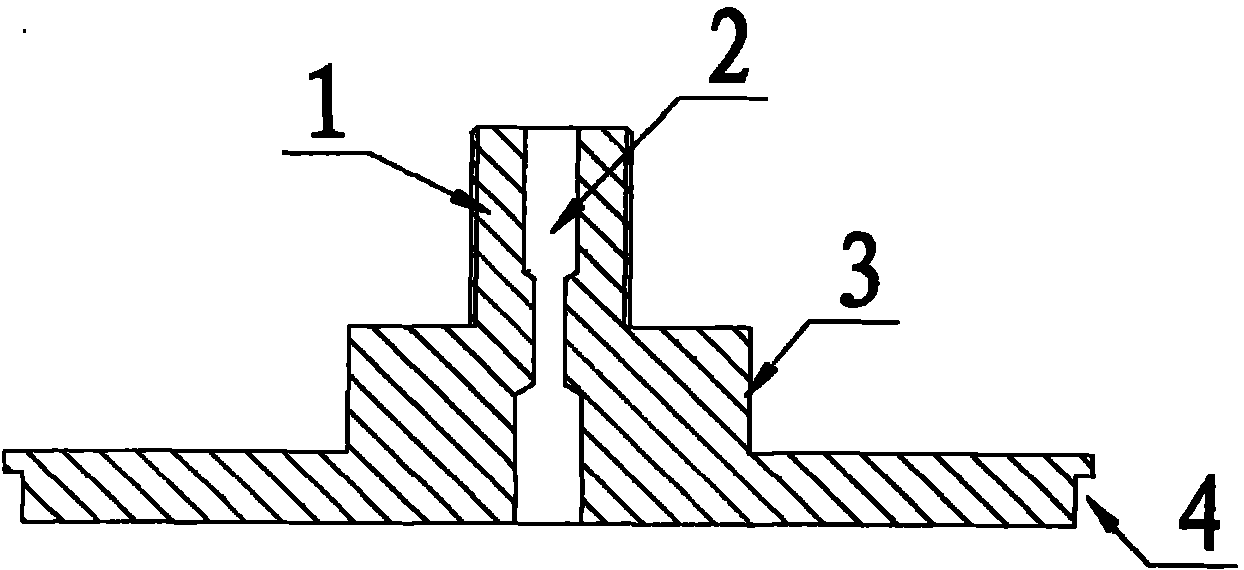

[0012] The positive electrode of the cylindrical lithium-ion battery is a cold-rolled 3003 aluminum alloy cap, the height of the top of the stud from the upper surface of the cover is 12 mm, and the outer diameter of the stud is 5 mm. The diameter of the upper and lower ends of the central hole of the stepped cylinder is 2mm, and the diameter of the central hole is 1mm. The upper diameter of the circumferential cover is 32 mm, the thickness is 0.5 mm, and the lower diameter of the circumferential cover is 31 mm.

Embodiment 2

[0014] The positive electrode of the cylindrical lithium-ion battery is a cold-rolled 3003 aluminum alloy cap, the height of the top of the stud from the upper surface of the cover is 15 mm, and the outer diameter of the stud is 8 mm. The diameter of the upper and lower ends of the central hole of the stepped cylinder is 3mm, and the diameter of the central hole is 1.5mm. The upper diameter of the circumferential cover is 40 mm, the thickness is 0.8 mm, and the lower diameter of the circumferential cover is 38.4 mm.

Embodiment 3

[0016] The positive electrode of the cylindrical lithium-ion battery is a cold-rolled 3003 aluminum alloy cap, the height of the top of the stud from the upper surface of the cover is 25 mm, and the outer diameter of the stud is 12 mm. The diameter of the upper and lower ends of the central hole of the stepped cylinder is 4mm, and the diameter of the central hole is 2mm. The upper diameter of the circumferential cover is 60 mm, the thickness is 1.0 mm, and the lower diameter of the circumferential cover is 58 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com