Energy-conserving drying device

A drying device, energy-saving technology, applied in drying, dryer, drying gas layout and other directions, can solve the problems of not more accurate utilization, differentiated treatment, energy waste, etc., to save energy, reduce heat loss, The effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

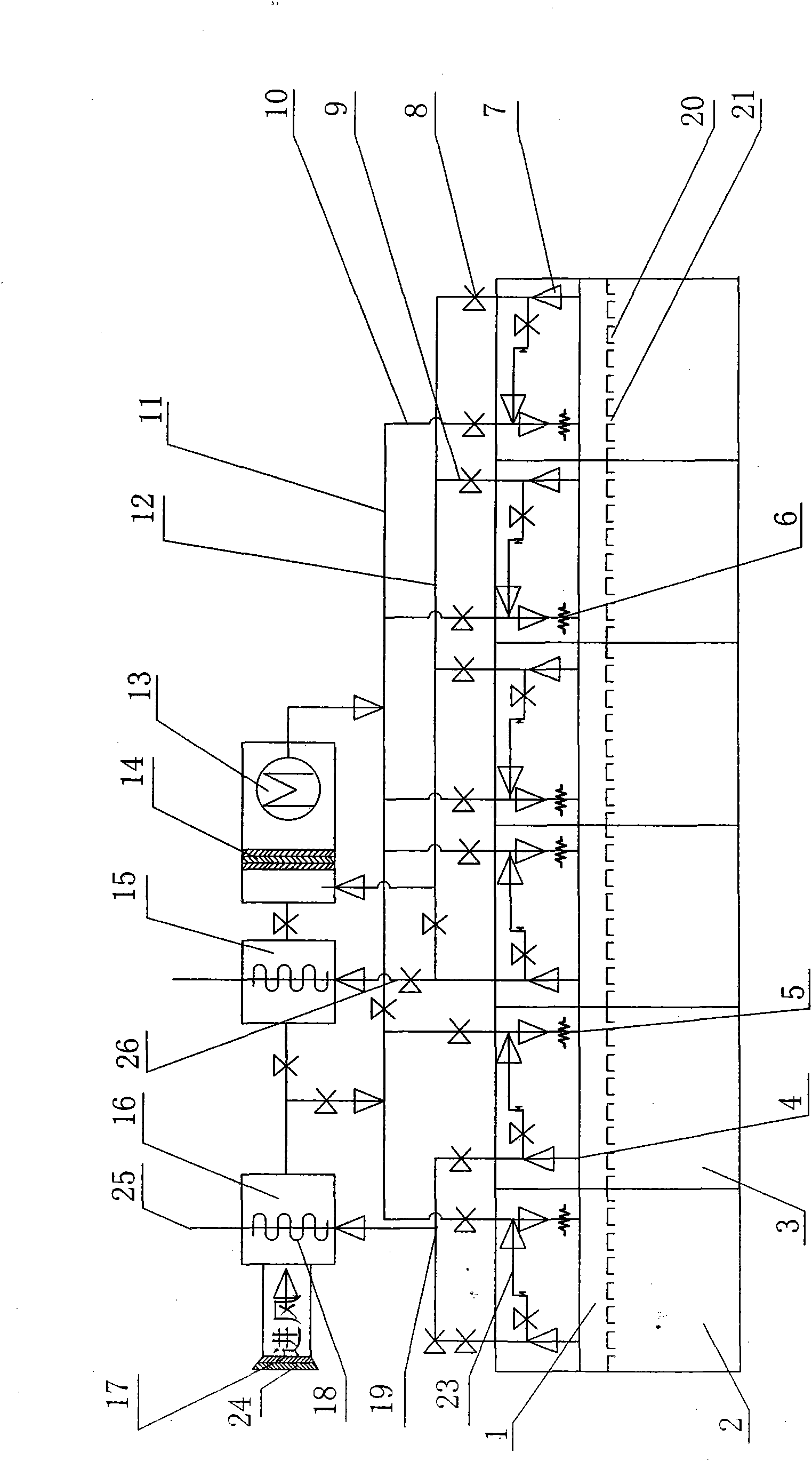

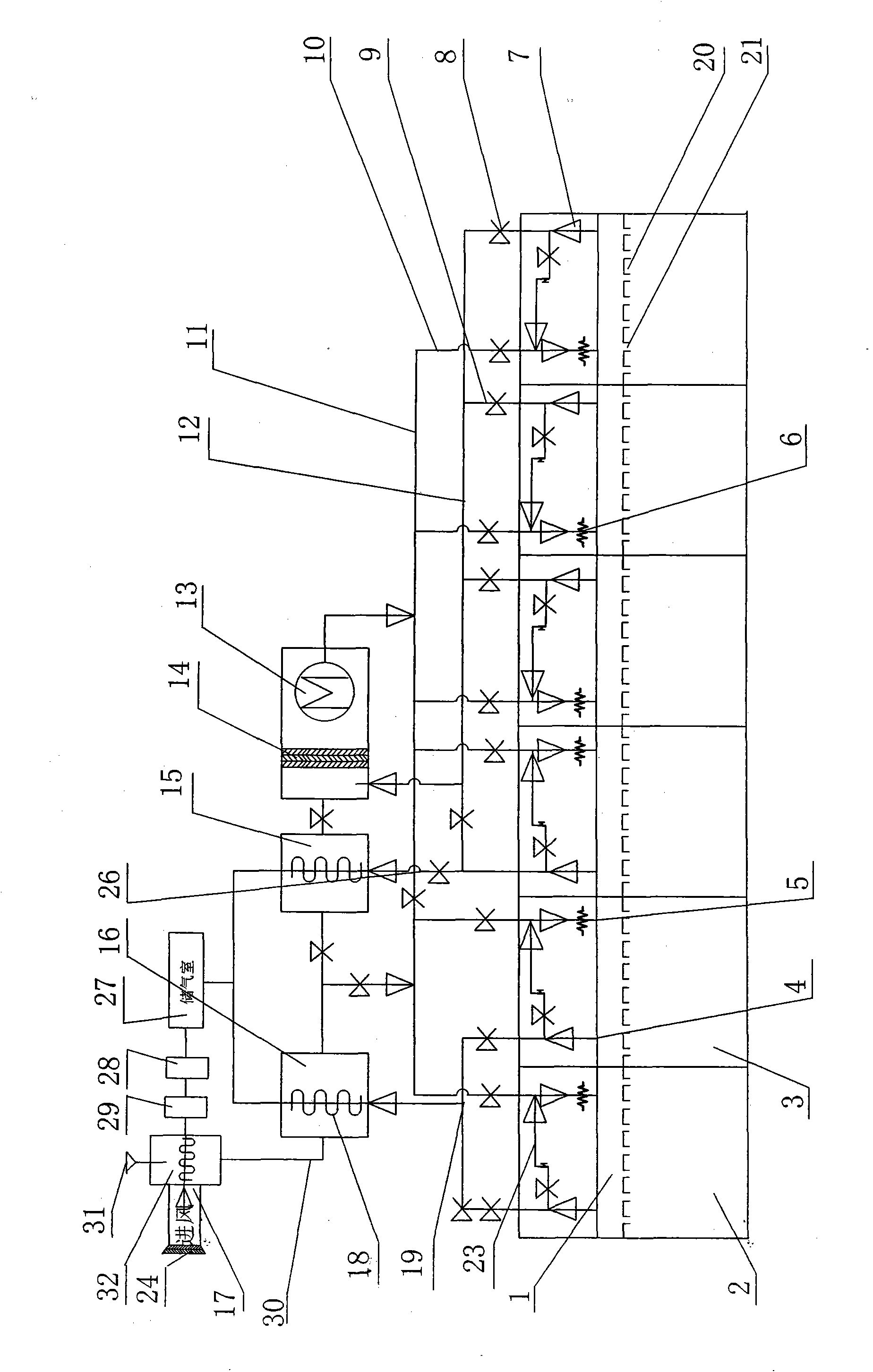

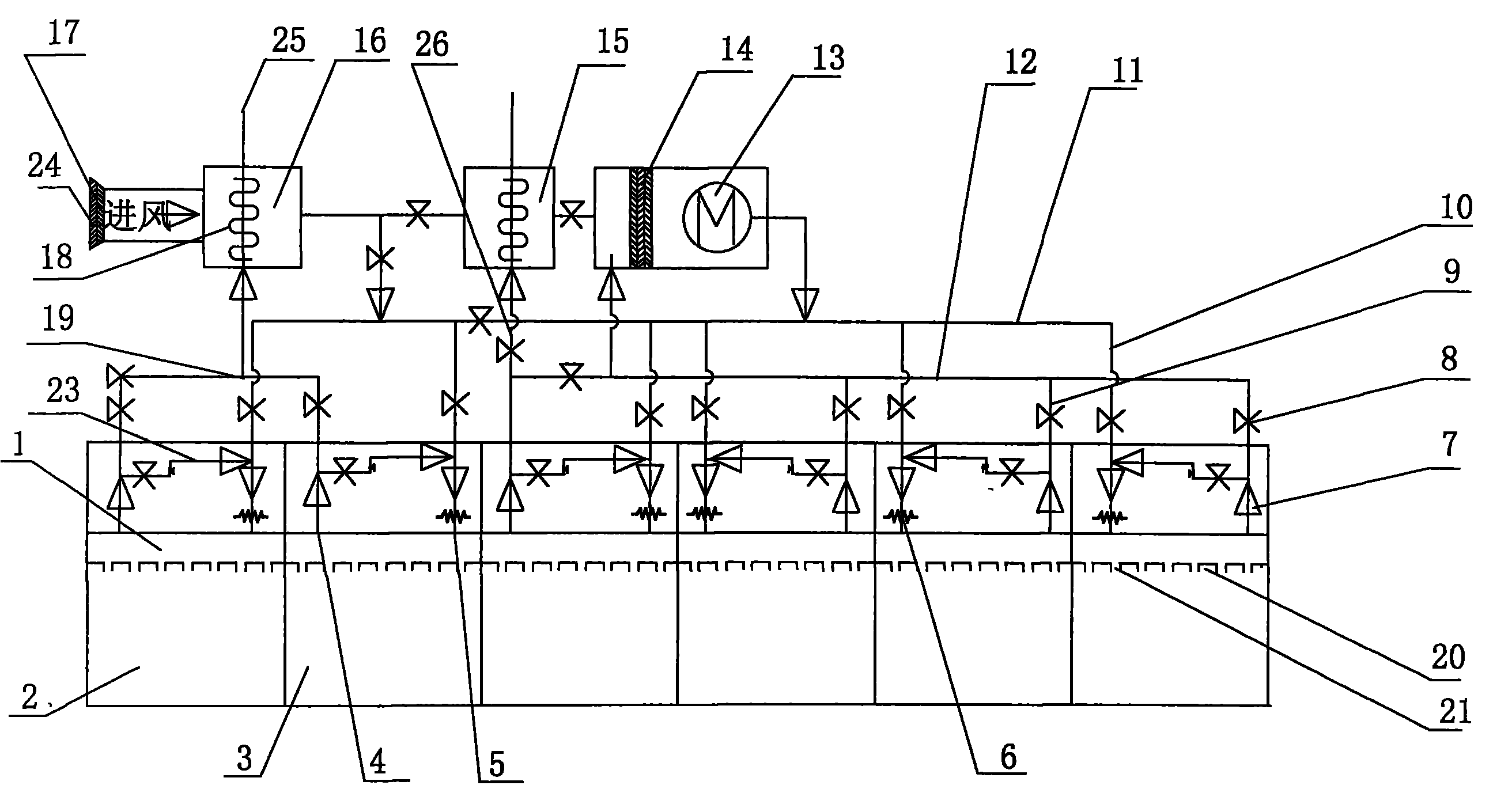

[0036] Such as figure 1 As shown, an embodiment of an energy-saving drying device of the present invention, in figure 1Among them, an energy-saving drying device, including: drying chamber 2, drying products is an important and indispensable process, and the various coatings used in these products usually contain volatile substances, which are sent into the drying chamber. The products in the drying chamber 2 are sequentially entered into each oven 3 by a conveyor (not shown in the figure) for drying and then flow into the next process. 17 After the air is taken, the fresh air is heated to a high-temperature gas through a heat exchanger. If the temperature does not meet the requirements, there is an electric heater 6 at the air inlet for supplementary heating. The heated hot air divides the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com