Air insulating structure of vacuum insulation panel and packaging method thereof

A technology of vacuum insulation board and air insulation, which is applied in heat exchange equipment, pipeline protection through heat insulation, heat preservation, etc., can solve the problems of easy generation of wrinkles in the production process, edge folding wrinkles, and influence of heat insulation performance, so as to reduce thermal bridges effect, saving packaging costs, and reducing the number of strips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

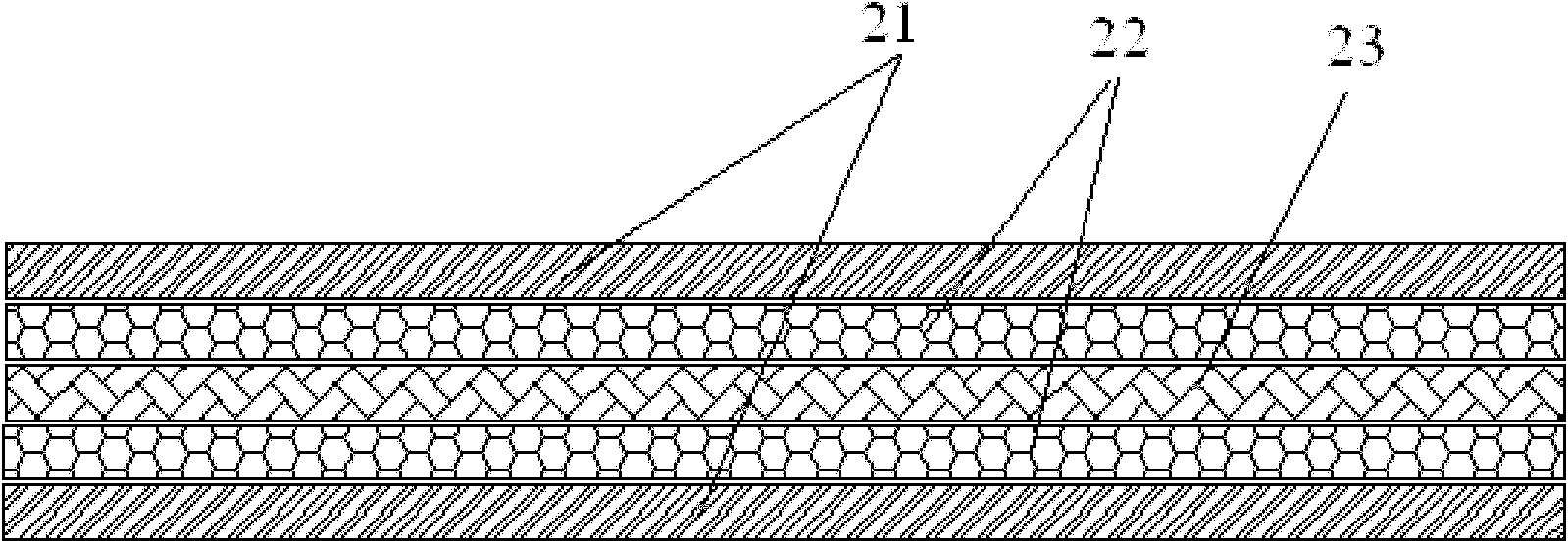

[0024] figure 2 It is a sectional view of the composite material used in the air barrier structure of the present invention. The composite material used comprises two heat-sealing layers 21 , two gas barrier layers 22 and one heat barrier layer 23 .

[0025] The heat-sealing layer is made of high-density polyethylene or polybutylene or vinyl ethyl acetate, and the gas-barrier layer is made of polyvinyl alcohol. If necessary, it can be coated with gas-barrier paint. Generally, acrylic varnish is used, and the heat-barrier layer is made of polyolefin. Layers, such as polyethylene, polypropylene or polyethylene copolymer, each layer is bonded with a polyurethane adhesive; generally the thickness of the gas barrier structure is 200-500 microns, pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com