Gas compressor and overpressure controller

A liquid and pressure plate technology, which is applied in the direction of machines/engines, liquid variable displacement machinery, mechanical equipment, etc., can solve the problems that hinder the widespread use of afterburning engine systems, and achieve the effect of low cost, low energy price and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

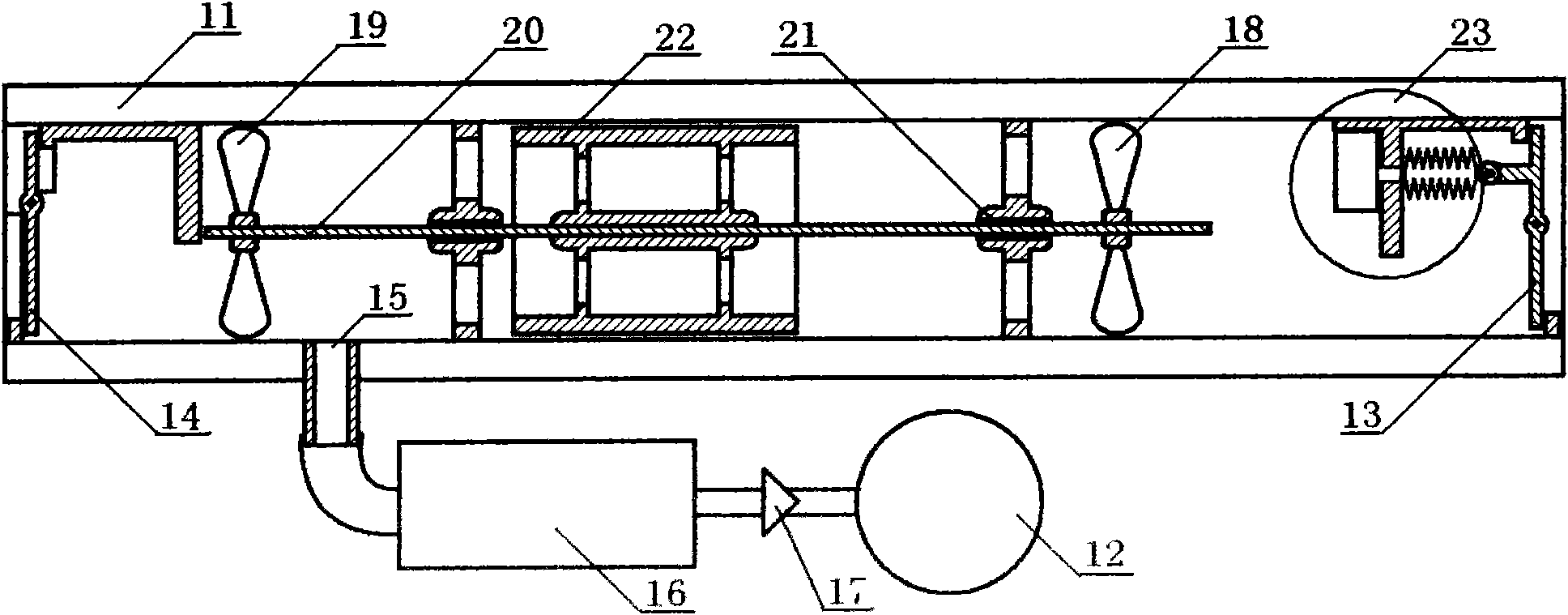

[0027] The real-time mode of the present invention will be described in detail below in conjunction with the accompanying drawings.

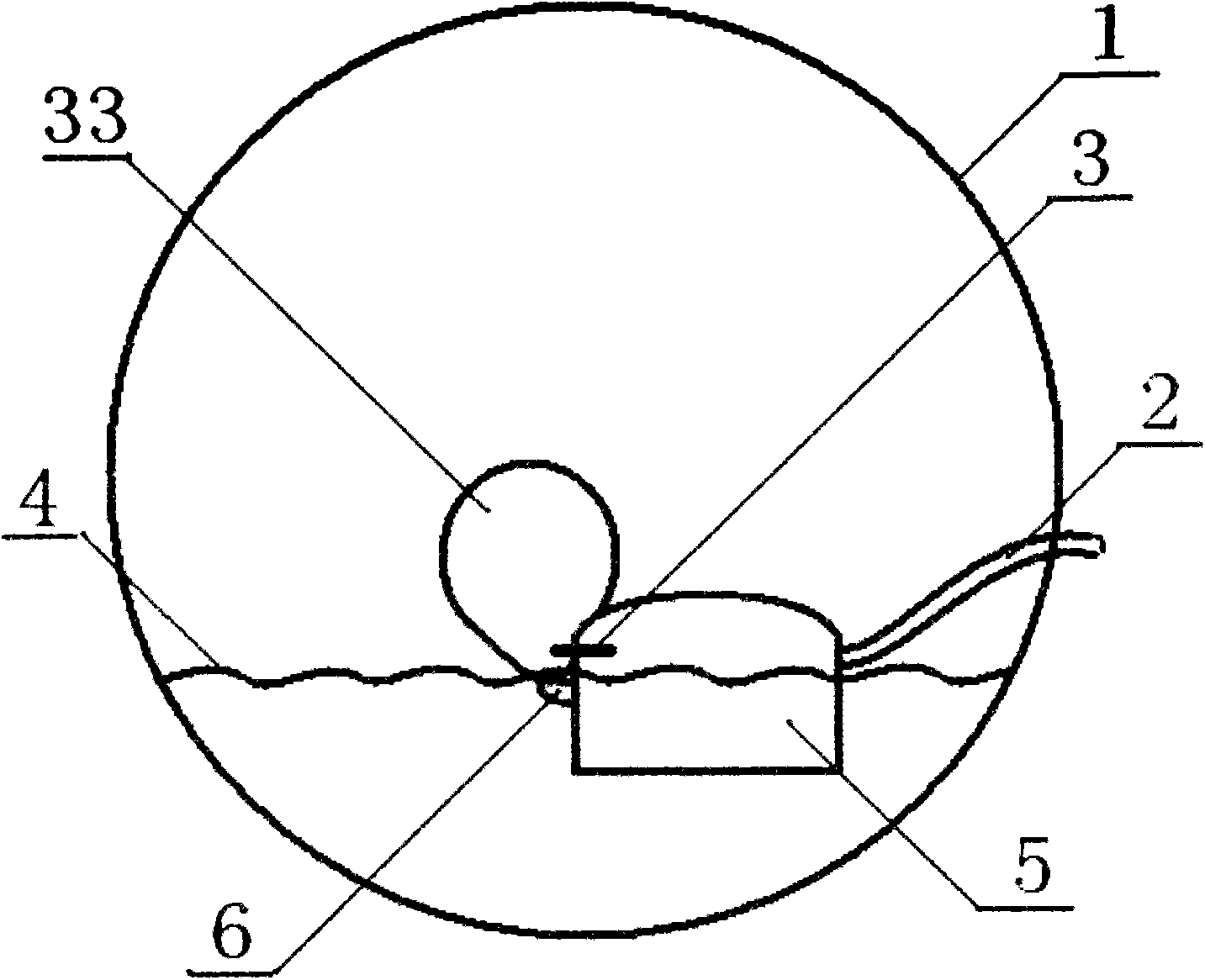

[0028] exist figure 1 middle

[0029] 1. Inner gas tank, including gas storage tank 1, intake pipe 2, and igniter 3, characterized in that: there is liquid 4 in the gas storage tank 1, and there is a floating plate 5 on the surface of the liquid, and the intake pipe 2 is connected to the floating plate 5 An igniter 3 is arranged on the floating plate, and the outlet 6 of the intake pipe is below the liquid level 4 .

[0030] This inner gas tank is suitable for rushing into viscous liquid, so that enough large bubbles 33 can be blown out.

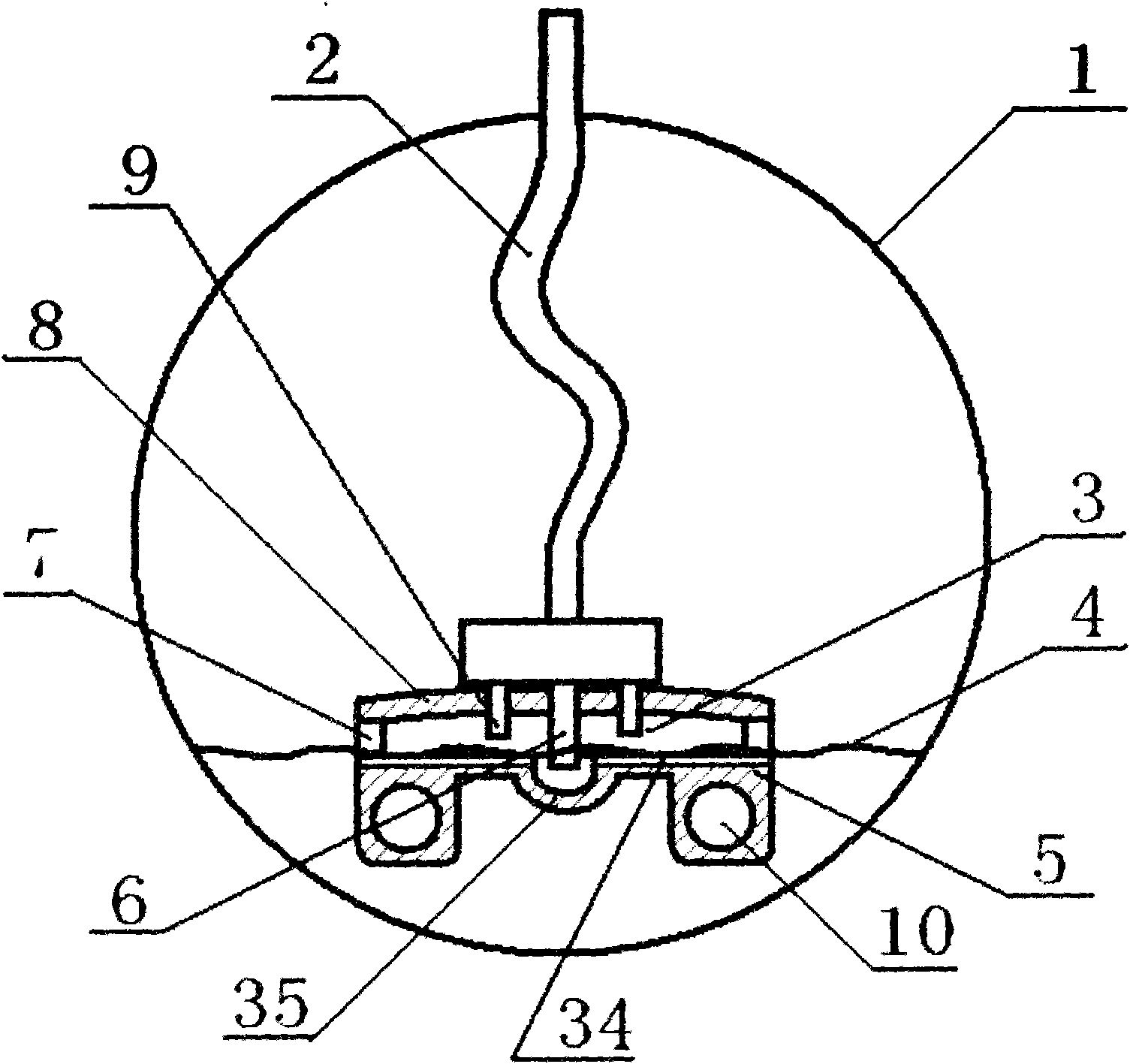

[0031] exist figure 2 middle

[0032] 2. Inner gas tank, including gas storage tank 1, intake pipe 2, and igniter 3, characterized in that: there is liquid 4 in the gas storage tank 1, there is a floating plate 5 on the surface of the liquid, and the intake pipe 2 is connected to the floating plate 5 On ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com