Splicable flange plate of bridge

A flange plate and bridge technology, applied in bridges, bridge parts, bridge materials, etc., can solve the problems of difficult to guarantee aesthetics, inconvenient construction, non-uniform outer flanges of edge beams, etc., to ensure the use of functions and overall coordination. Aesthetics, the effect of convenient continuous construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] Example 1, when a super-large bridge crosses and intercommunicates, a section of intercommunicating main line bridge is formed. Due to the design of the ramp, the edge of the roadbed has different shapes, forming many special-shaped structures.

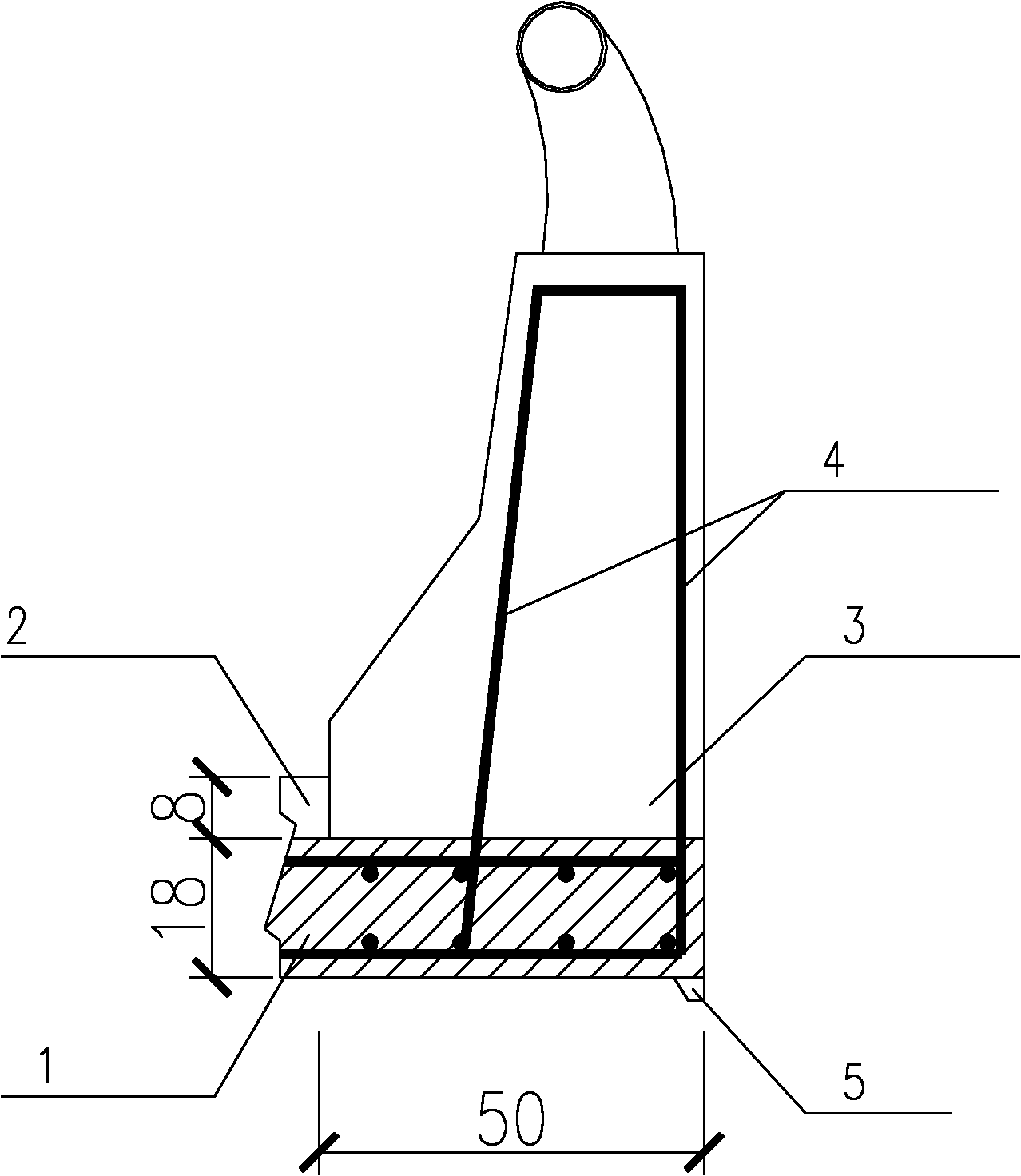

[0084] The flanges of all prefabricated beams all adopt the spliceable flange plates of the present invention, refer to image 3 . The side and top of the spliceable flange plate 1 are provided with reserved connecting reinforcement bars 7 and 9 .

[0085] Such as Figure 8-Figure 10 : This extra-large bridge all adopts the prefabricated and assembled composite box girder at the front and rear standard subgrade width parts, so the construction is fast and the cost is low. But after entering the interchange section, due to the non-standard width subgrade, if the conventional design method is adopted, the integral box girder of cast-in-place construction will be used. The construction of this kind of box girder is slow, the cos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com