Molding method of scroll and scroll

A molding method and scroll-type technology, which is applied in the direction of rotary piston pumps, rotary piston machines, machines/engines, etc., can solve problems such as complex process, demoulding draft angle, mold bursting, etc., and achieve processing technology Simple, guaranteed dimensional accuracy, strong mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

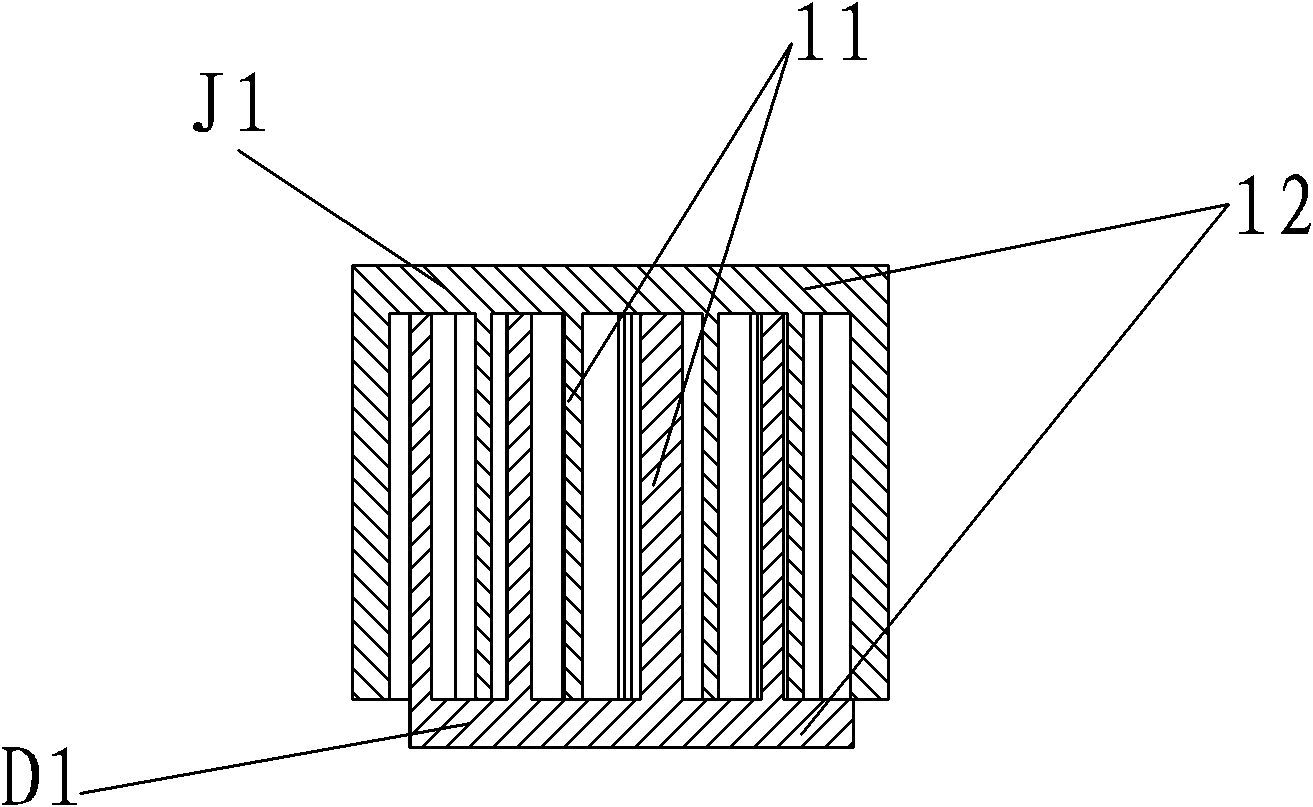

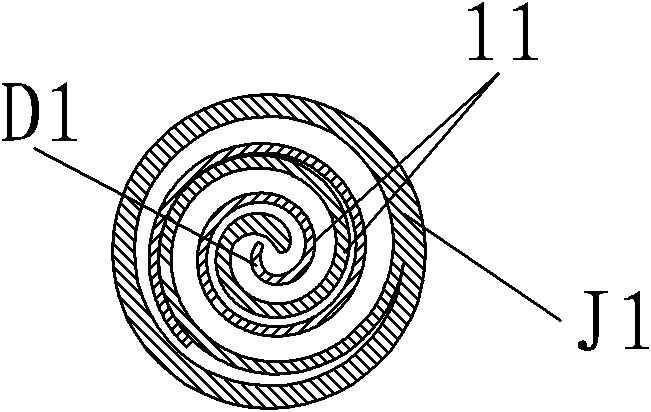

[0033] 1. Form the scroll profile 11 according to the following scroll profile molding method;

[0034] Since the scroll profiles of the movable scroll and the fixed scroll are the same or similar, we set them as completely consistent in this embodiment, so the formation of the scroll profiles does not need to be distinguished. Its molding method is as follows:

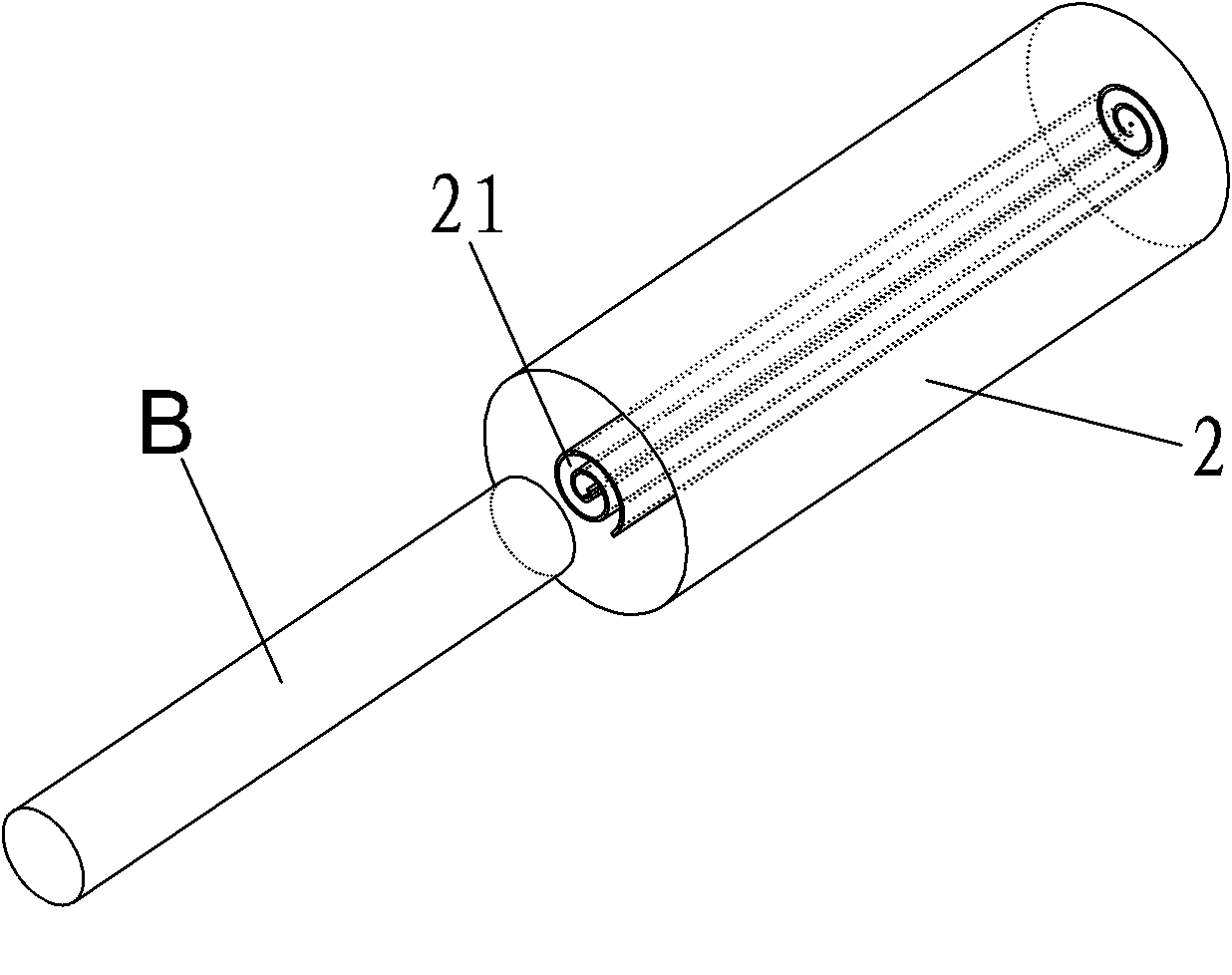

[0035] 1. According to the structural parameters of the scroll profile 11, a cavity 21 is made as a through-type scroll profile mold 2;

[0036] 2. Through hot extrusion (only heating the billet to the forging process temperature, of course different forging temperatures are different for different raw materials) to make the scroll profile blank B (generally aluminum alloy rod or steel) pass through the scroll profile mold 2 The through-type cavity 21 is extruded to obtain the scroll profile 3;

[0037] 3. According to the height parameter of the scroll profile, the scroll profile 3 is cut to obtain the scroll profi...

Embodiment 2

[0054] The difference between this embodiment and the first embodiment is that the scroll end covers of the fixed scroll and the movable scroll are not formed by extrusion, but formed by existing die-casting technology. The swirl-shaped wire is still extruded according to the molding method of the swirl-shaped wire in the first embodiment.

[0055] In this way, the fixed scroll scroll end cover J12 and the outer ring J13 of the fixed scroll can be integrally formed, and an installation groove corresponding to the scroll profile line 11 is reserved on the scroll end cover, without further It is set as a hollow groove, but it can be a blind groove, and the width of the groove is slightly smaller than the width of the scroll line; as Figure 14 shown. Then, the scroll profile obtained according to the scroll profile forming method in the first embodiment is fixed on the scroll end cover J12 of the fixed scroll by way of interference fit.

[0056] Similarly, the movable scroll s...

Embodiment 3

[0059] The difference between this embodiment and Embodiment 1 is that the scroll profile 11, the scroll end cover J12 of the fixed scroll, the outer ring J13 and the scroll end cover D12 of the movable scroll are all made by cold extrusion ( Without heating the billet) the billet (usually aluminum alloy rod) is extruded through the through-type cavity of the mold, and then assembled.

[0060] Of course, the present invention also has other deformation forms, such as the scroll end cover of the movable scroll is obtained by extruding through a through-type die, and the scroll end cover and outer ring of the fixed scroll are integrally formed by die-casting, etc. The technical personnel process the scroll profile and the scroll end cover separately, and then assemble the scroll disc, all of which fall within the protection scope of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com