Paddy shelling rice-polishing mill

A rice mill and paddy technology, applied in grain hulling, grain processing, grain pod removal, etc., can solve problems such as heavy labor, and achieve the effect of improving workability, realizing equipment area, and lowering the loading position.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

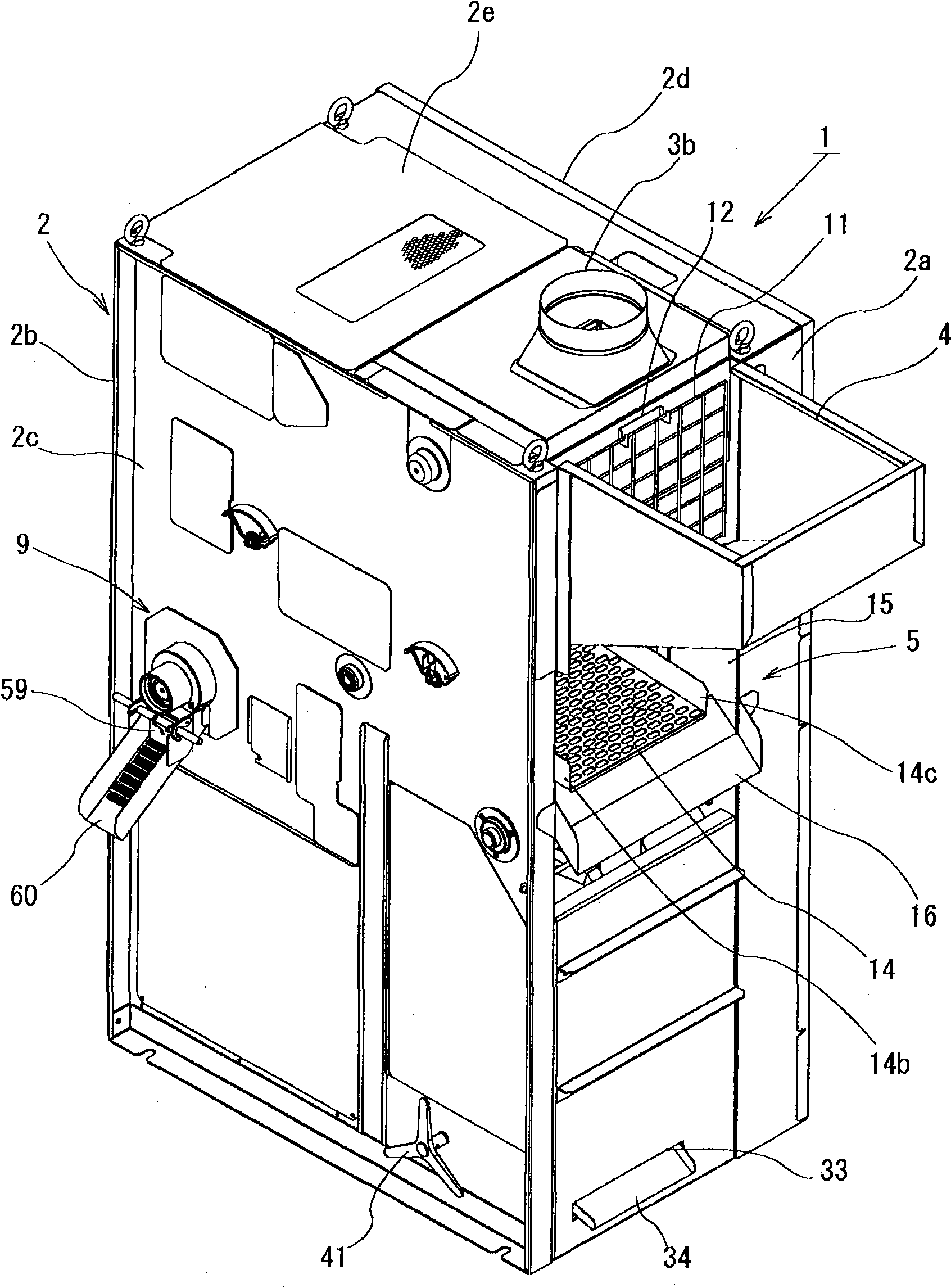

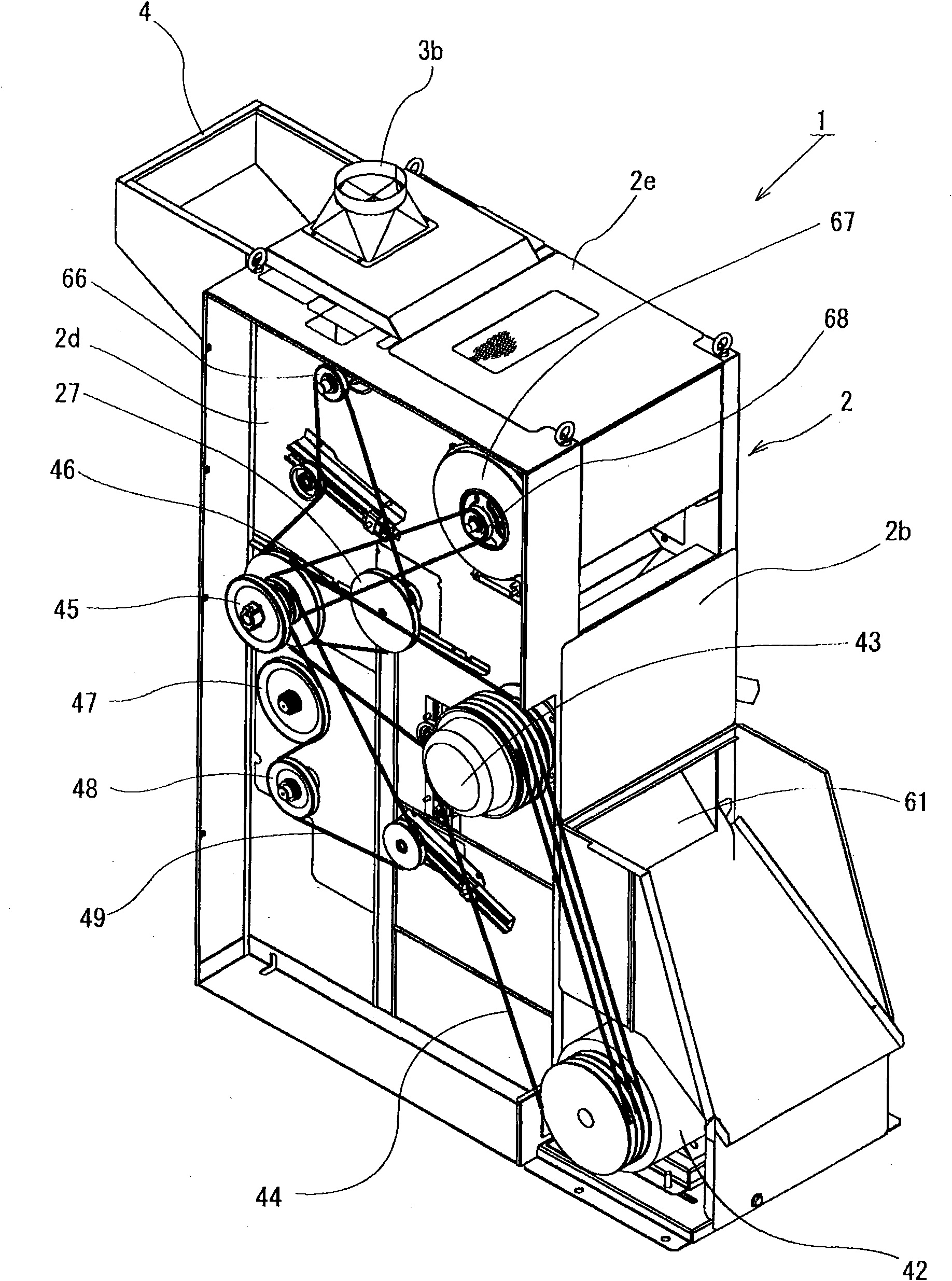

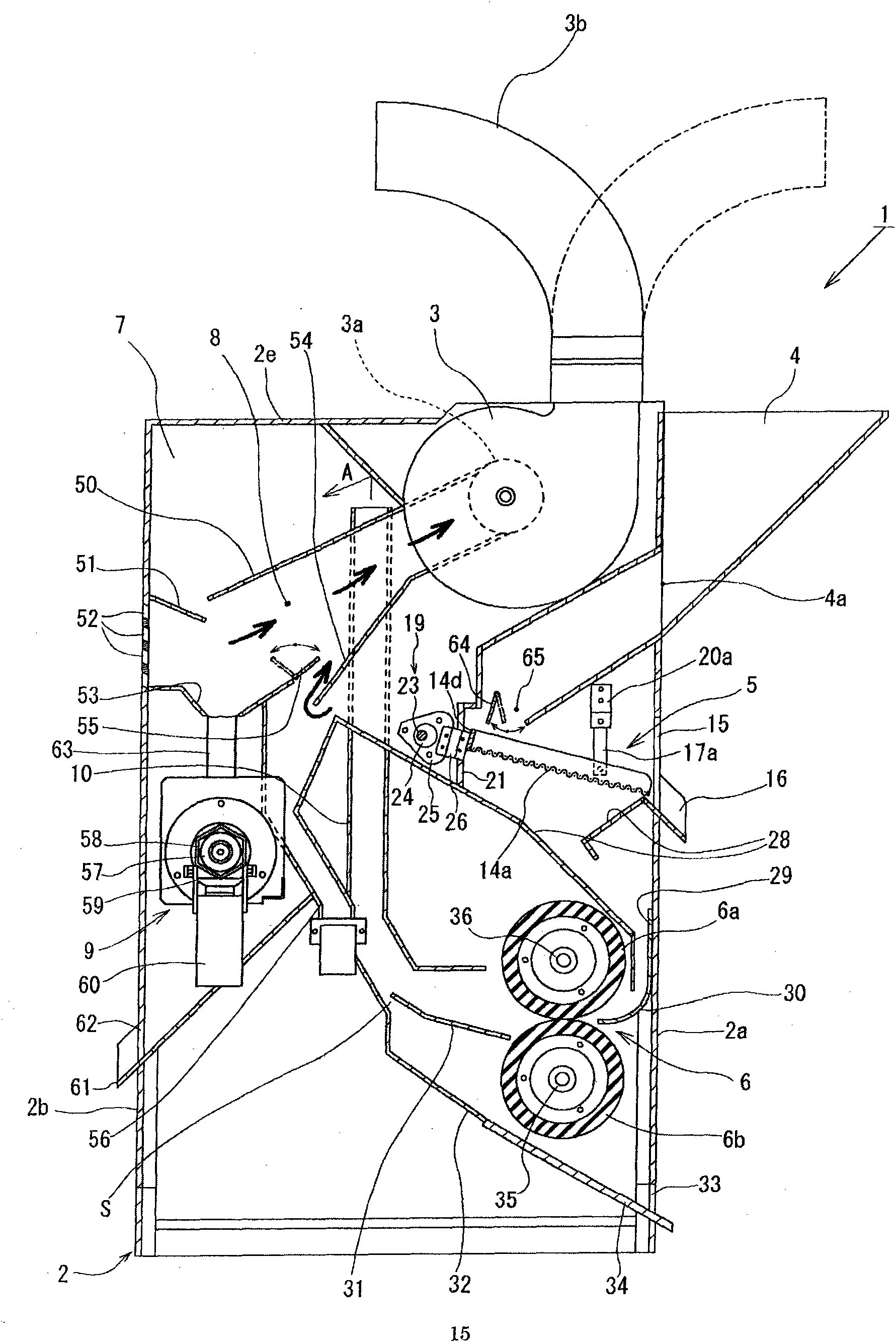

[0026] The best mode for carrying out the present invention will be described with reference to the drawings. figure 1 It is a schematic perspective view looking at the front side of the paddy husking and rice milling machine according to the embodiment of the present invention from the upper right obliquely, figure 2 It is a vertical cross-sectional view of the rear side of the paddy husking and rice milling machine according to the embodiment of the present invention viewed from the upper right obliquely, image 3 It is a rough longitudinal sectional view. First, the overall structure of the device will be described in terms of "outline", and then the structure of each part will be described.

[0027] (summary)

[0028] Figure 1 to Figure 3 The paddy husking rice mill 1 which concerns on embodiment of this invention is shown. The paddy husking and milling machine 1 is provided with the front wall 2a, the rear wall 2b, the left side wall 2c, the right side wall 2d, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com