Rectification device

A technology of rectification and tower still, which is applied in the field of di-tert-butyl dicarbonate rectification device, can solve the problems of high technical energy consumption, cumbersome operation procedures, long working hours, etc., achieve good product purity, reduce production cost, and recover high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

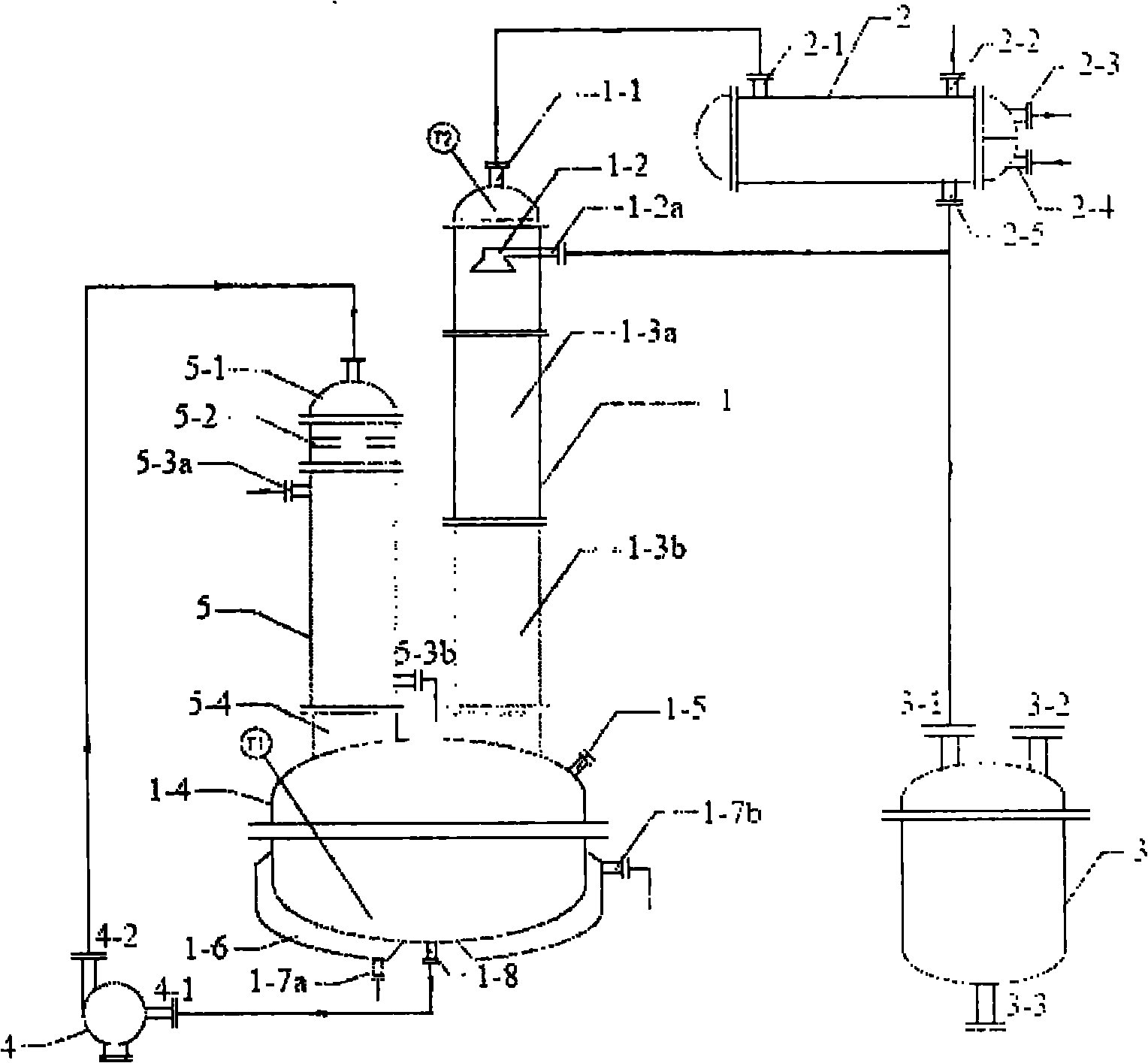

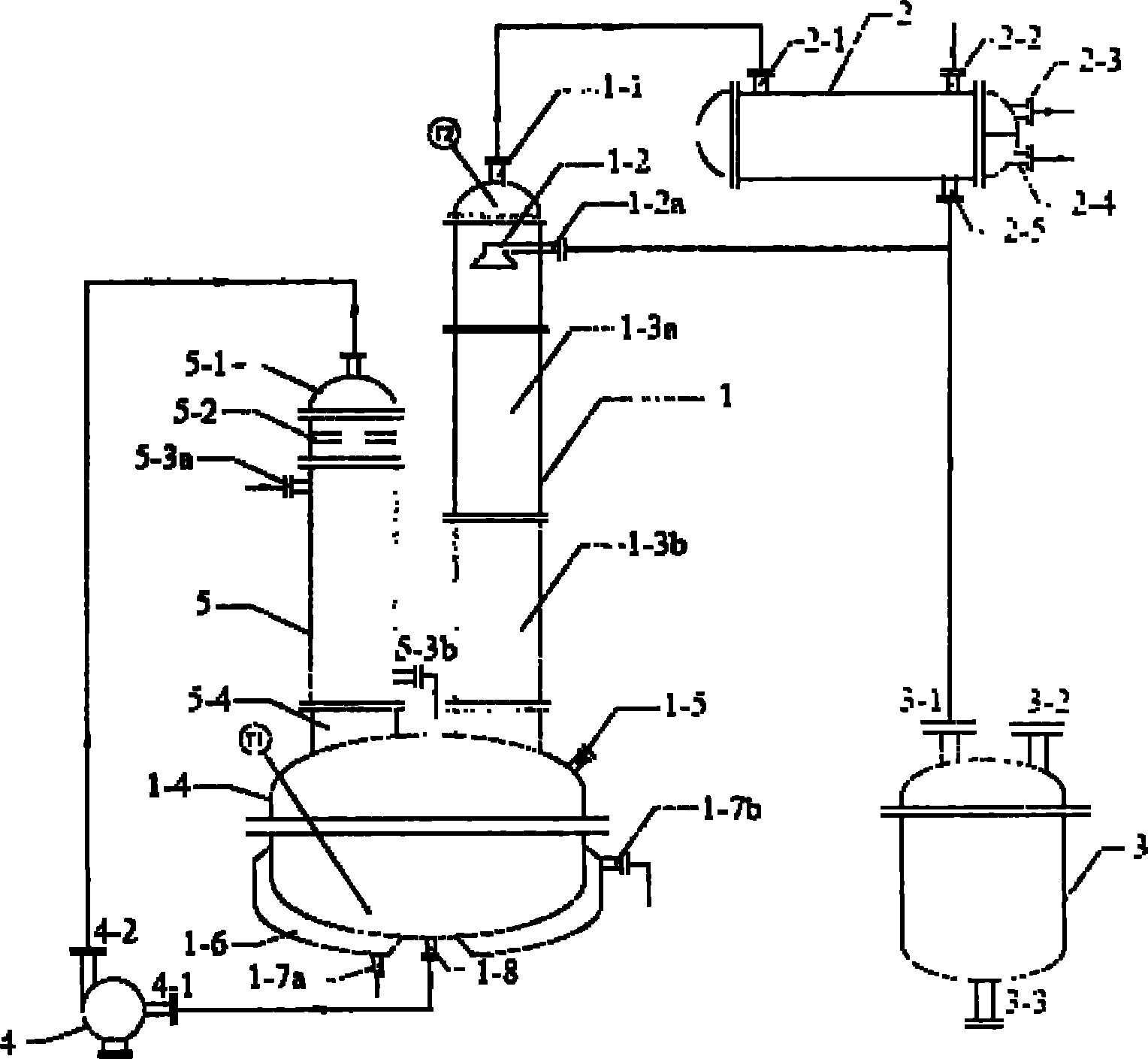

[0012] Such as figure 1 As shown, the rectification device includes a tower kettle 1-4, a circulation pump 4, a falling film reboiler 5, a tower column 1, a condenser 2 and a receiving tank 3; the tower kettle 1-4 is provided with a feed port 1-5 and thermometer T1; one end of the falling film reboiler 5 is arranged on the top of the tower kettle, and the other end is connected with the bottom of the tower kettle through the circulating pump 4, and a heating mechanism is arranged in the falling film reboiler 5, and the The temperature mechanism includes a steam inlet 5-3a and a steam outlet 5-3b; the tower column 1 is set on the tower kettle 1-4, and the top of the tower column 1 is provided with a gas phase pipe interface 1-1, a thermometer T2 and a liquid distributor 1-2, The gas phase pipe interface 1-1 is connected to the condenser 2; the condenser 2 is provided with a gas phase inlet 2-1, a vent port 2-2, a cooling water inlet 2-4, a cooling water outlet 2-3 and a condens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com