Permanent magnet rotating motor with high torque density, high power density and low disturbance

A high power density, rotating electrical machine technology, applied in the direction of synchronous machine parts, magnetic circuit shape/style/structure, winding conductor shape/style/structure, etc., can solve the problem of poor heat dissipation of the rotor and shaft, and achieve reduction Effect of torque disturbance, increasing torque density and power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

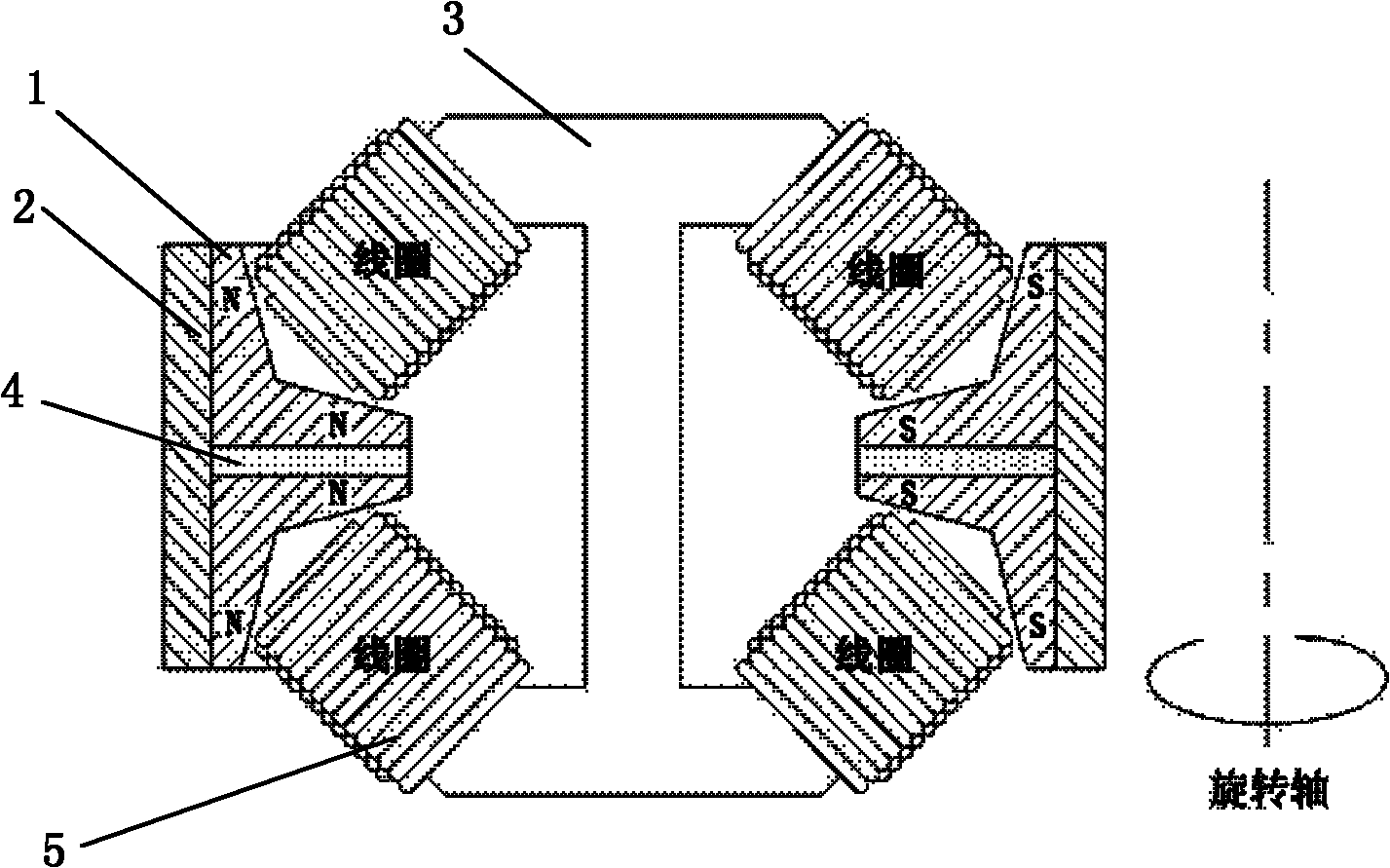

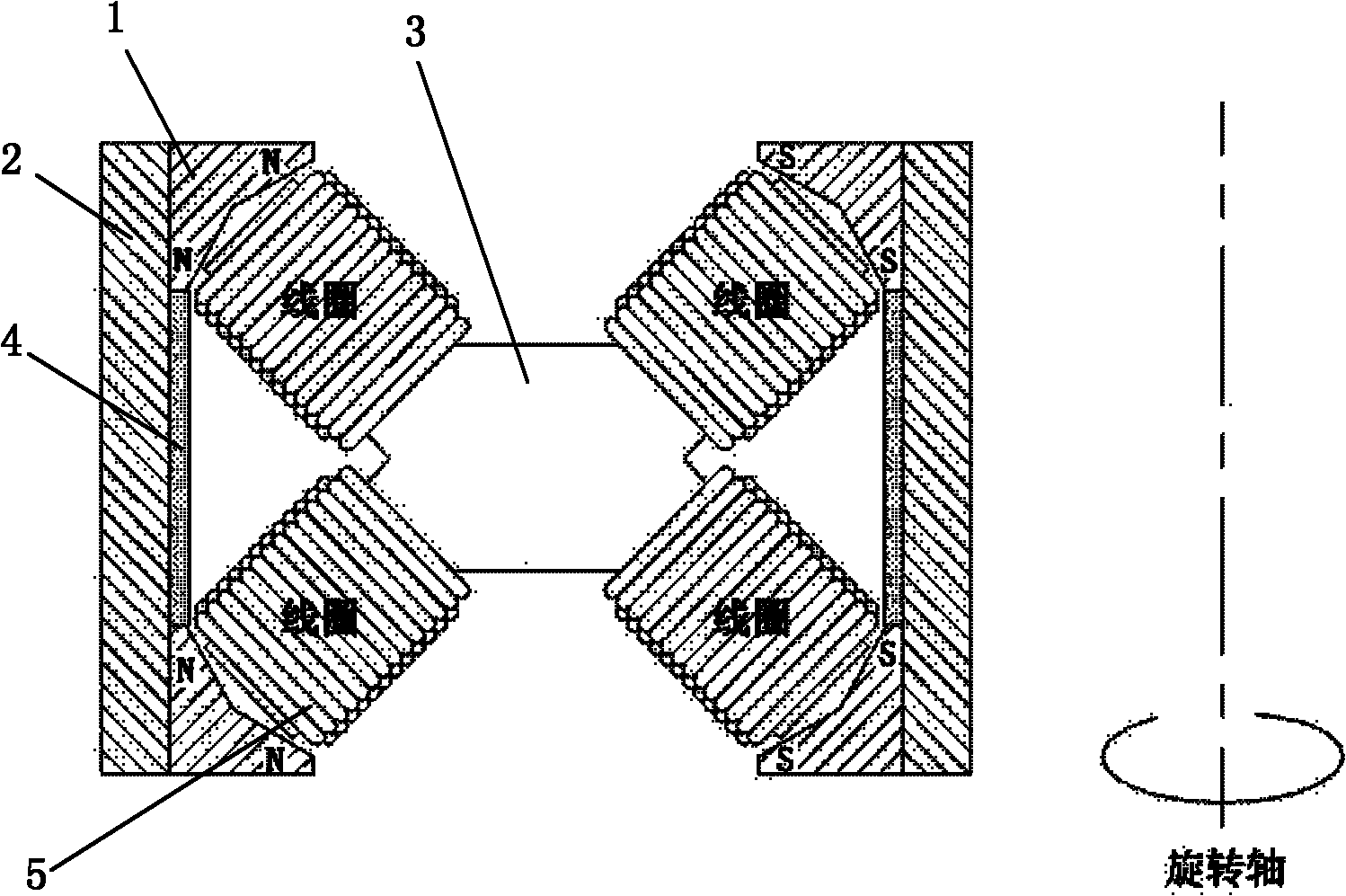

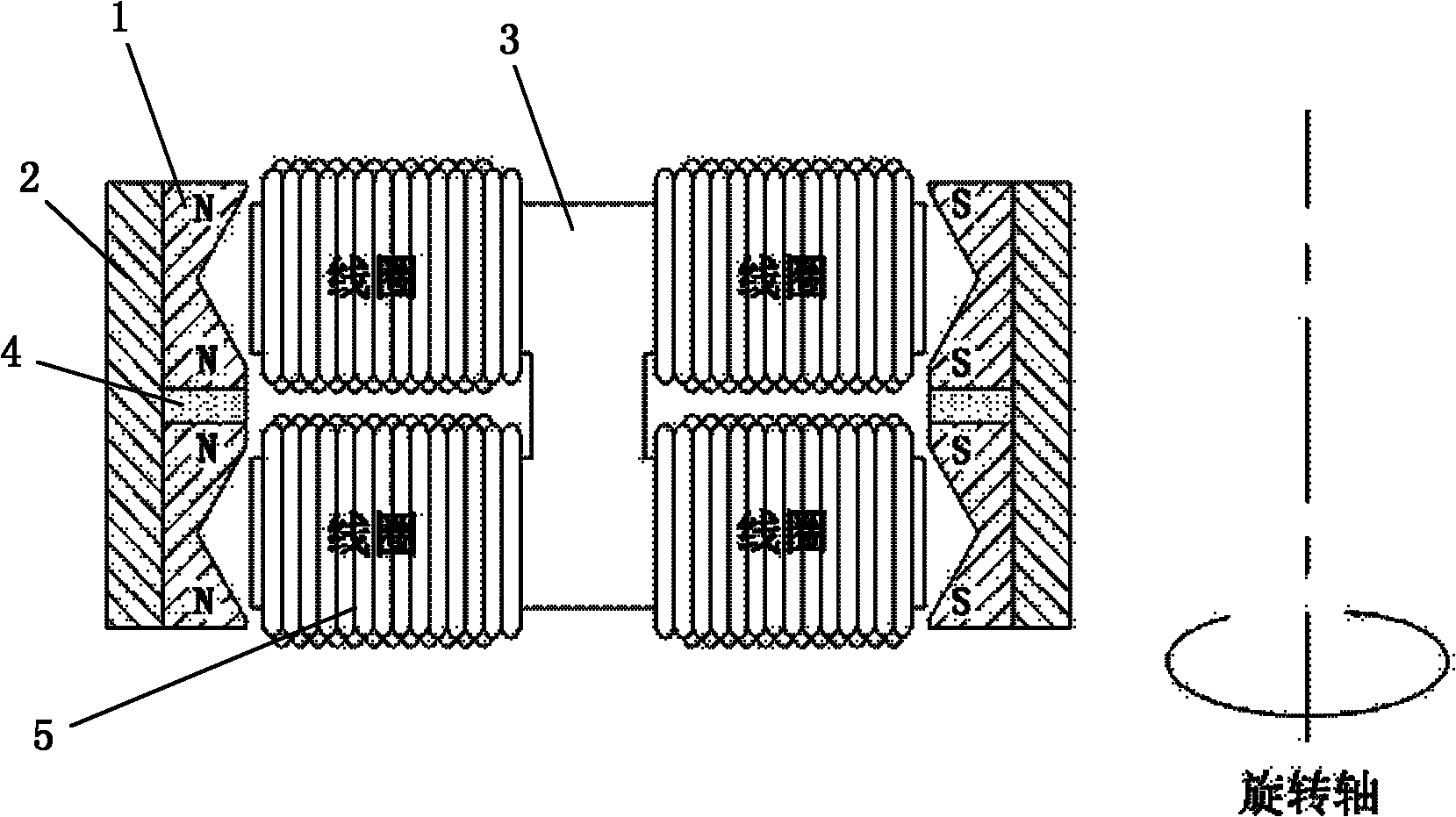

[0030] Please refer to the attached figure 1 , 2 , 3, 4, 5, and 6 show that the arrangement of permanent magnets in space is sequentially expanded along the perimeter and arranged in a double V shape, that is, two pairs of V-shaped permanent magnets of the same polarity are used along the perimeter. arrangement;

[0031] In the radial direction, corresponding to it, on the inner surface of the double V-shaped magnetic steel, there are two pairs of V-shaped magnetic steels of the same polarity arranged along the circumference. When the rotor is outside, the opposite type (such as attached figure 1 ), in the case of including the rotor, adopt the back-to-back type (as attached Figure 5 ).

[0032] In the axial direction, that is, two pairs of V-shaped permanent magnets with the same polarity are arranged on the upper and lower sides of the rotating shaft. The polarity of the magnet is reversed. In this axial magnetic steel arrangement, the winding direction of the upper a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com