Anti-explosion main junction box for high-voltage compact motor

A main junction box, compact technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems affecting the personal safety of surrounding workers, affecting the safety of junction boxes, unreliable sealing performance, etc., and achieve reasonable electrical clearance and creepage distance, avoid partial discharge, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

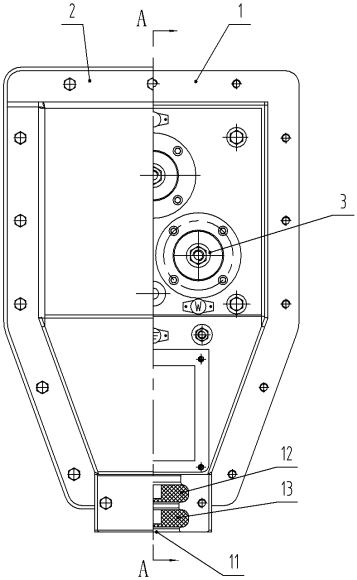

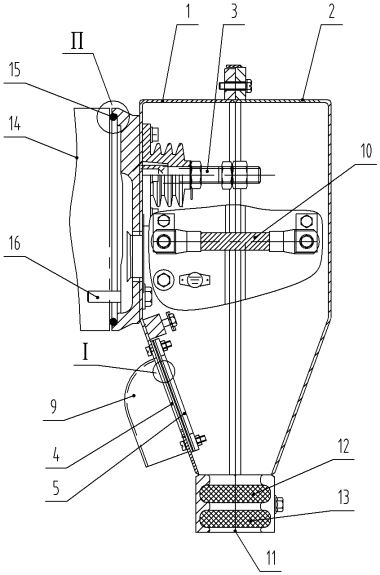

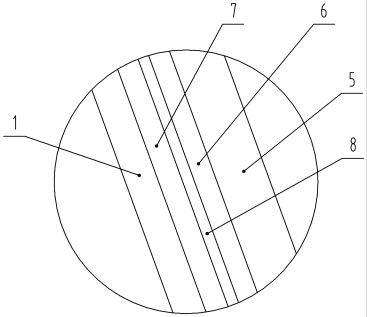

[0019] like Figure 1~4 As shown, the explosion-proof main junction box for a high-voltage compact motor of the present invention includes a box base 1 that is detachably and sealingly connected with the motor body 14, and a box cover 2 that is detachably and sealingly connected with the box base 1, and the box base 1 is provided with wiring The column 3, the lower part of the box base 1 is provided with a pressure relief hole 4, the box base 1 is provided with a hollow pressure plate 5 inside the pressure relief hole 4, and there are two layers of hollow gaskets 6 and seals between the pressure plate 5 and the box base 1. There is a layer of pressure relief film 8 between the gasket 7, the gasket 6 and the gasket 7, the pressure relief membrane 8 is made of copper foil or tin foil, and the box seat 1 is provided with a protective cover 9 with a downward opening on the outside of the pressure relief hole 4 , The protective cover 9 is a cube structure, which is convenient for r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com