Trough type separator of rice hull chain boiler

A chain boiler and separator technology, applied in lighting and heating equipment, etc., can solve the problems of failure to meet the design and use requirements, deformation and falling off of the trough separator, and large thermal expansion, so as to avoid oxidation and thermal expansion and deformation, and have a long service life , the effect of reducing carbon content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

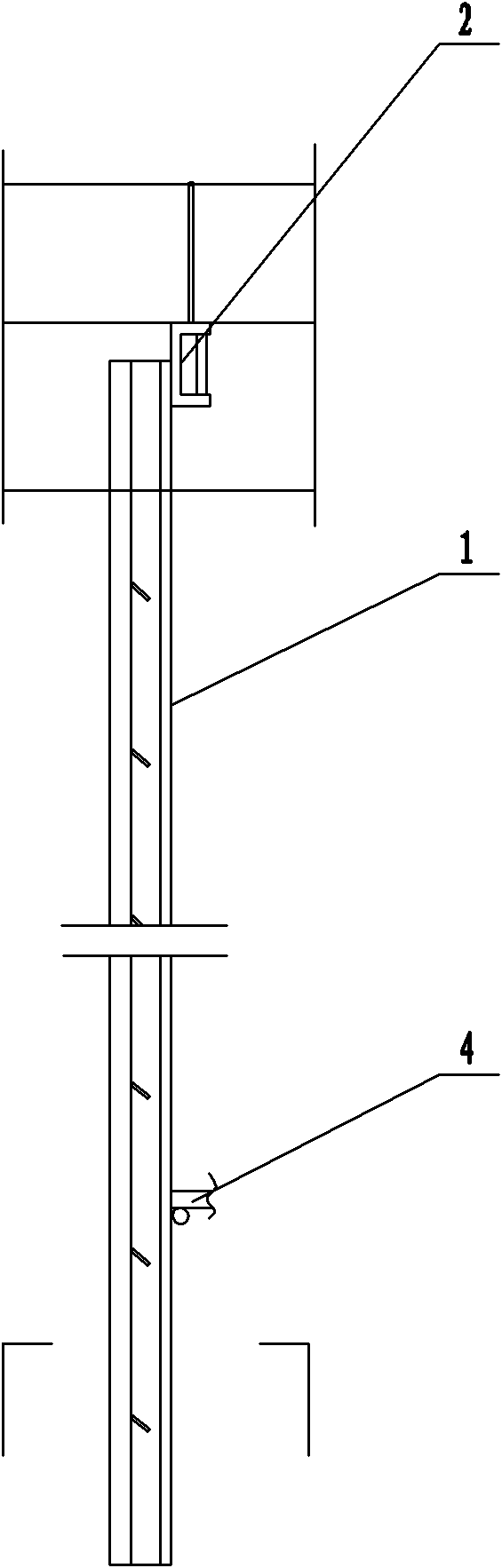

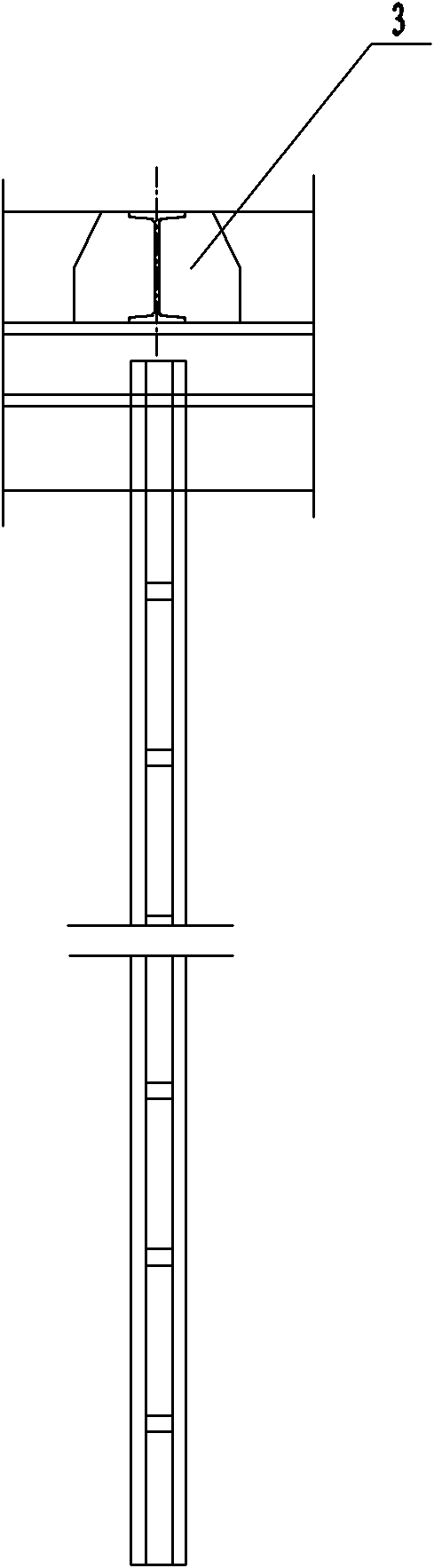

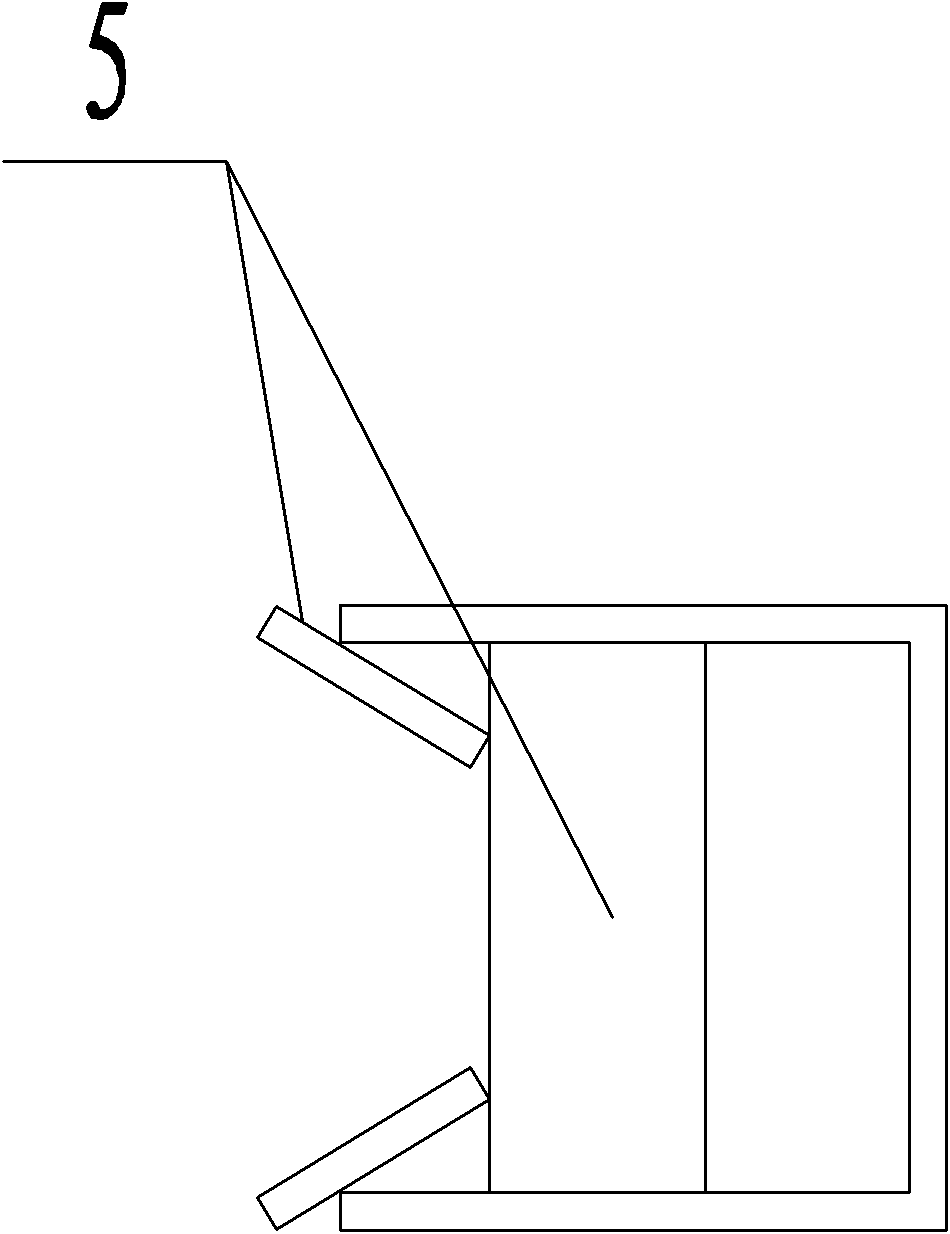

[0012] like Figure 1 ~ Figure 3 As shown, it includes a separation tank body 1, a top connecting beam 2, a stiffener plate 3, an anti-sway connection device 4 and a deflector 5.

[0013] The separation tank body 1 of the present invention is vertically arranged, and a deflector 5 is arranged in the separation tank body 1, and passes through the furnace roof upwards to connect with the top connecting beam 2; the top connecting beam 2 is arranged on the top of the boiler. A reinforcing rib plate 3 is provided at the joint between the top connecting beam 2 and the roof, and the top connecting beam 2 is connected with the boiler roof through the reinforcing rib plate 3; the anti-sway connecting device 4 is arranged at the lower part of the separator. The anti-sway connection device 4 is composed of alloy round steel connections.

[0014] Working princip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com