Complete two-stage slurry production equipment of water-coal-slurry and gasified water-coal-slurry by using low-rank coal fuel

A technology of low-rank coal and coal-water slurry, which is applied in the field of complete sets of production equipment for low-rank coal fuel coal-water slurry and gasification coal-water slurry in two-stage pulping, and can solve the problem of low flow velocity of coal-water slurry ball mill and coal slurry particle size distribution Unreasonable, low concentration of coal water slurry products, etc., to achieve the effect of reducing grinding power consumption, reducing viscosity, and optimizing particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

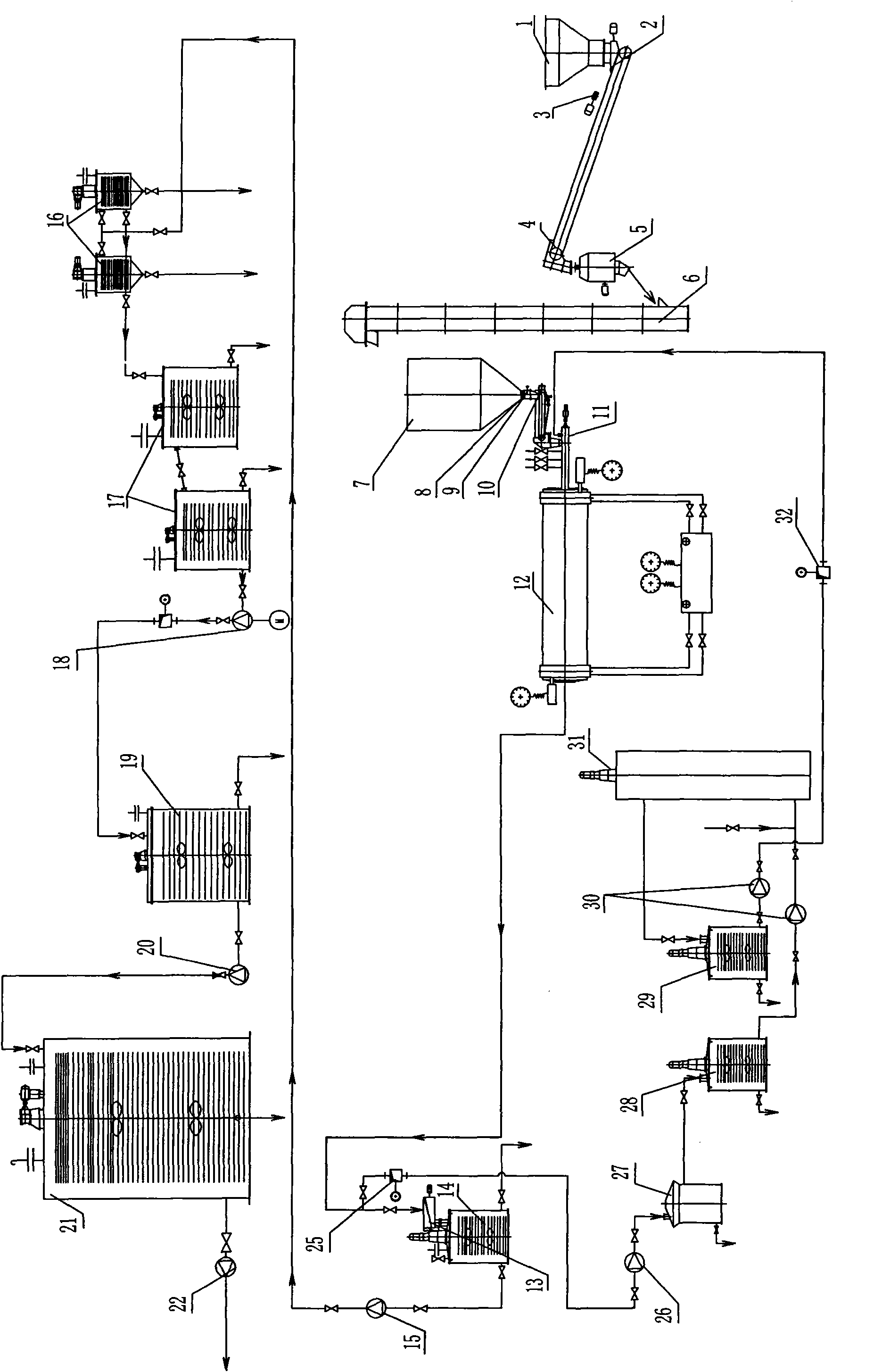

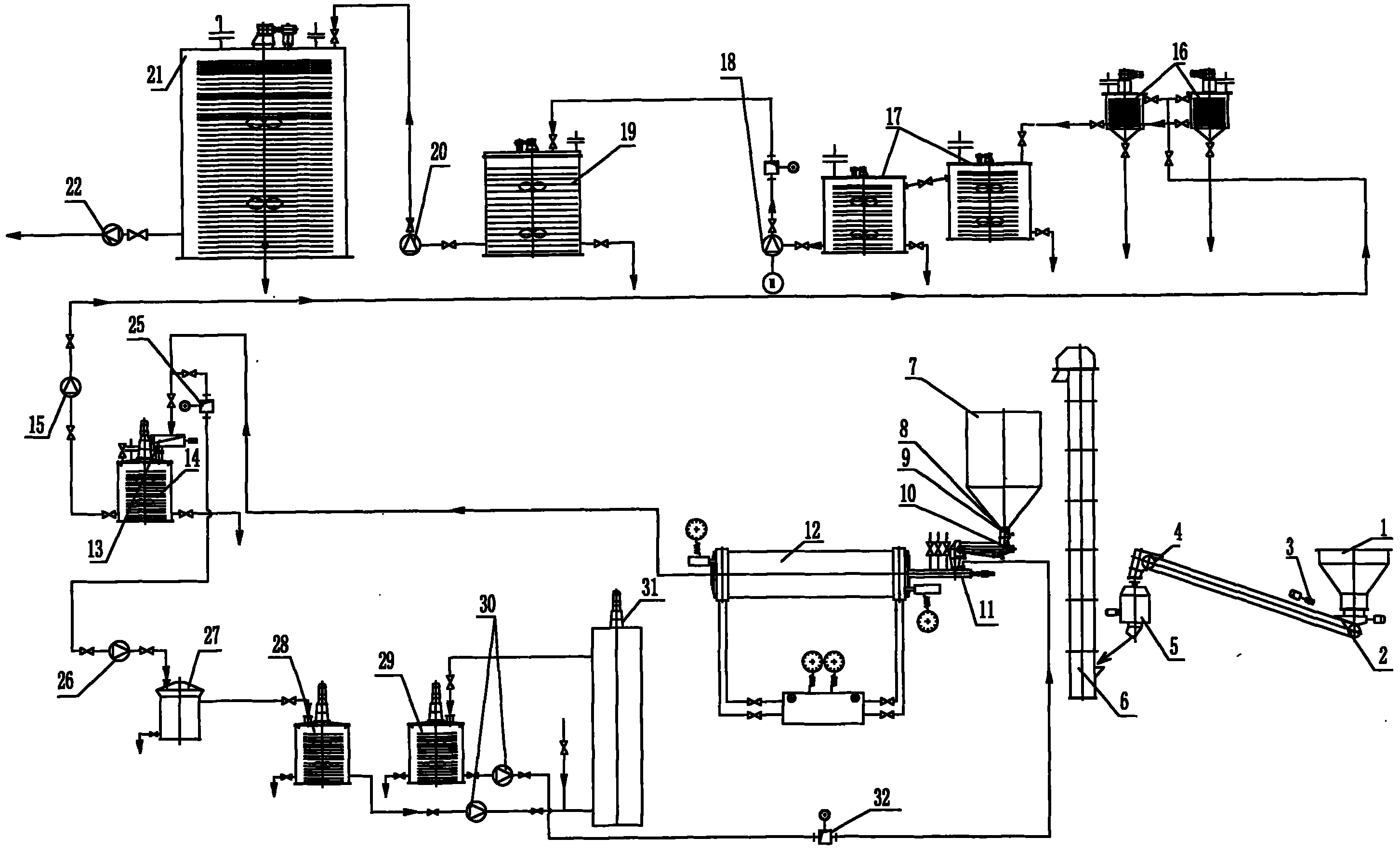

[0013] see figure 1 , figure 1 It is a schematic diagram of the overall structure of the complete set of production equipment for two-stage pulping low-rank coal fuel coal-water slurry and gasification coal-water slurry of the present invention. Depend on figure 1 It can be seen that the complete set of production equipment for low-rank coal fuel coal-water slurry and gasification coal-water slurry for two-stage pulping of the present invention includes a low-rank coal raw material bin 1, a vibrating feeder 2, a belt conveyor 4, and a reversible impact hammer crusher. Machine 5, bucket elevator 6, low-rank coal intermediate bin 7, metering belt conveyor 10, screw feeder 11, high-concentration coal-water slurry ball mill 12, coal-water slurry vibrating screen 13, coal-water slurry buffer tank 14, water Coal slurry filter 16, stability treatment barrel 17, homogeneous tank 19, slurry storage tank 21, rotary vibrating screen 27, fine mill inlet tank 28, medium concentration ult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com