Neutral inorganic composite material for dehydration, solidification and modification of high water content sludge

An inorganic composite material and sludge dehydration technology, which is applied in dehydration/drying/thickened sludge treatment, solid waste management, climate sustainability, etc., can solve problems such as alkalinity and secondary pollution, and achieve reduction of stench, High compressive strength, low price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

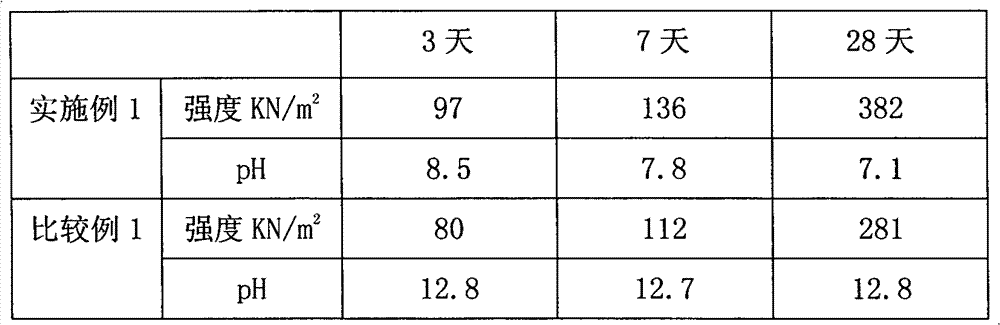

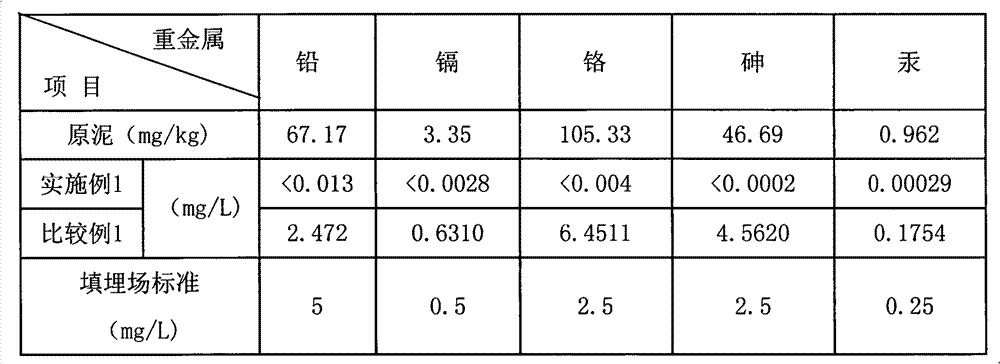

Embodiment 1

[0023] A kind of neutral inorganic composite material which is rapidly dehydrated and solidified and modified by sludge, and takes the following components by weight fraction:

[0024] 100 parts of hydraulic solidification material, which is composed of: 50 parts of hemihydrate gypsum, 50 parts of light magnesium oxide;

[0025] 80 parts of inorganic water-absorbing ash materials, paper mill incineration ash;

[0026] 20 parts of inorganic auxiliary hardening material, silica sand in foundry, particle size is 15-60 μm;

[0027] 2 parts of polymer coagulant, polyacrylamide;

[0028] 1 part of modified functional agent, get 250 parts of potassium chloride, 200 parts of calcium chloride, 22 parts of potassium permanganate, 175 parts of magnesium sulfate, 3 parts of nickel sulfate, 200 parts of sodium sulfate, 13 parts Calcium lignosulfonate and 1 part of citric acid are compounded, and 1 part of modified functional agent after compounding is taken;

[0029] The above-mentioned...

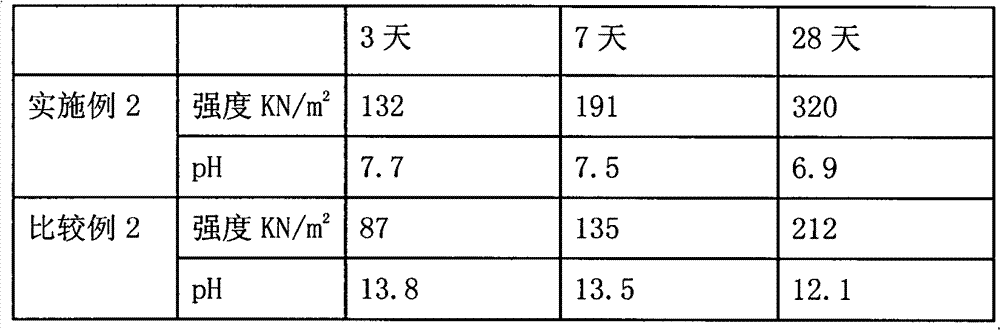

Embodiment 2

[0037] A kind of neutral inorganic composite material which is rapidly dehydrated and solidified and modified by sludge, and takes the following components by weight fraction:

[0038] 100 parts of hydraulic solidification material, which is composed of: 65 parts of hemihydrate gypsum, 35 parts of light magnesium oxide;

[0039] 100 parts of inorganic water-absorbing ash materials, paper mill incineration ash;

[0040] 30 parts of inorganic auxiliary hardening material, silica sand in foundry, particle size 80-120 μm;

[0041] 8 parts of polymer coagulant, sodium polyacrylate;

[0042] 5 parts of modified functional agent, get 200 parts of potassium chloride, 250 parts of calcium chloride, 20 parts of potassium permanganate, 150 parts of magnesium sulfate, 3 parts of nickel sulfate, 225 parts of sodium sulfite, 10 parts of Sodium lignosulfonate and 2 parts of malic acid are compounded, and 5 parts of modified functional agent after compounding are taken;

[0043] The above-...

Embodiment 3

[0051] A kind of rapid dehydration of sludge, solidification modified neutral inorganic composite material, take the following components by weight fraction:

[0052] 100 parts of hydraulic solidification material, which is composed of: 58 parts of hemihydrate gypsum, 42 parts of light magnesium oxide;

[0053] 120 parts of inorganic water-absorbing ash materials, paper mill fly ash;

[0054] 40 parts of inorganic auxiliary hardening material, silicon powder in foundry, particle size 100-150 μm;

[0055] 4 parts of polymer coagulant, sodium carboxymethyl cellulose;

[0056] 3 parts of modified functional agents, which consist of 290 parts of potassium chloride, 230 parts of calcium chloride, 25 parts of potassium permanganate, 200 parts of magnesium sulfate, 2 parts of nickel sulfate, 200 parts of sodium sulfite, 20 parts 3 parts of acryl alcohol polyoxyethylene ether and 3 parts of sodium hexametaphosphate are compounded, and 3 parts of modified functional agent after compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com