Imitation marble and method for manufacturing bathroom equipment by using same

A technology of artificial marble and hardener, applied in chemical instruments and methods, coatings, layered products, etc., can solve the problems of service life impact, complicated process, long time, etc., and achieve smooth production, simple equipment, and short time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

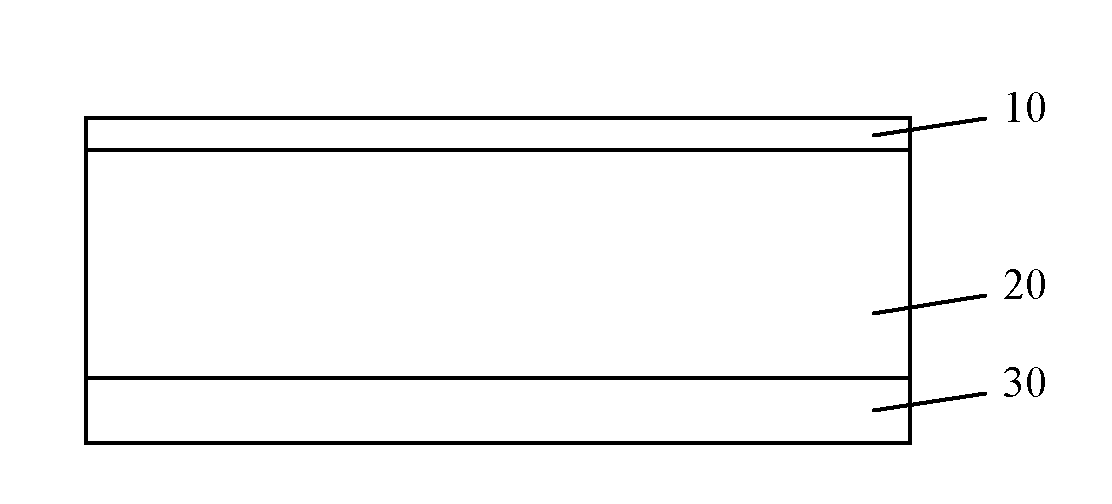

[0044] A type of artificial marble whose structure see figure 1 , comprising three layers of waterproof surface layer 10, unsaturated polyester resin middle layer 20 and reinforcing bottom layer 30.

[0045] Among them, the waterproof surface layer 10 adopts a mixture of NR3ZP transparent gel coat, retarder TBC (playing to delay the hardening time, so that the air of the surface gel coat can escape before hardening), and hardener M-50. The mass ratio of the three is 1:0.03:0.0001.

[0046] Wherein the reinforcing bottom layer 30 adopts a mixture of DS396S unsaturated polyester resin and hardener M-50VR, wherein the mass ratio of DS396S unsaturated polyester resin to hardener M-50VR is 1:0.05; or adopts DS396S unsaturated polyester resin , hardener M-50VR, glass fiber mixture.

[0047] Wherein the unsaturated polyester resin middle layer 20 comprises the following raw materials:

[0048] Resin U-250C accounted for 34%

[0049] Glass powder 80S accounts for 65%

[0050] Def...

Embodiment 2

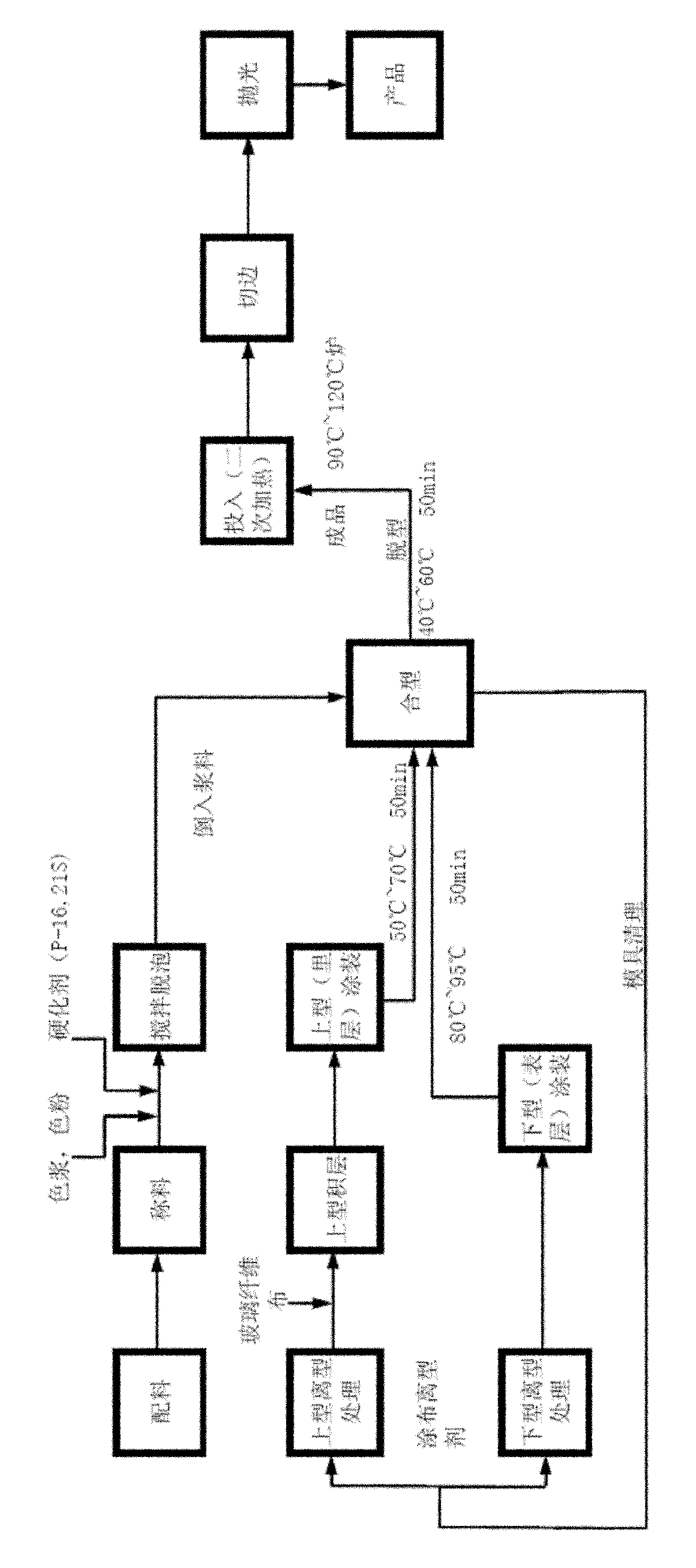

[0056] A method for manufacturing artificial marble bathroom equipment, the detailed process flow can be found in figure 2 , including the following steps:

[0057] Step 1: Prepare unsaturated polyester resin slurry:

[0058] Mix resin U-250 and glass powder 80S at a ratio of 1:2.5, then add defoamer BYK-A515 and accelerator NLF-10 accounting for 1% to 2% of the mixture to prepare a preliminary slurry; The weight of the bathroom equipment is weighed separately: according to the color of the finished product to be produced, weigh the required color paste and toner, and the ratio is to weigh 0.01% to 15% of the preliminary slurry, and weigh the required hardener 21S and P-16; when used, pour the weighed color paste, toner, hardener 21S and P-16 into the preliminary slurry, stir and mix, and stir and defoam in a vacuum state to obtain the slurry;

[0059] Step 2: Preparation of upper and lower molds:

[0060] Remove the foreign matter and sundries in the mold, and then apply ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com