High polymer hot-press mold with changeable cavity and use method thereof

A hot-pressing mold and variable cavity technology, applied in the field of material forming, can solve the problems of test result error, time-consuming, single sample size, etc., and achieve the effect of small test result error and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

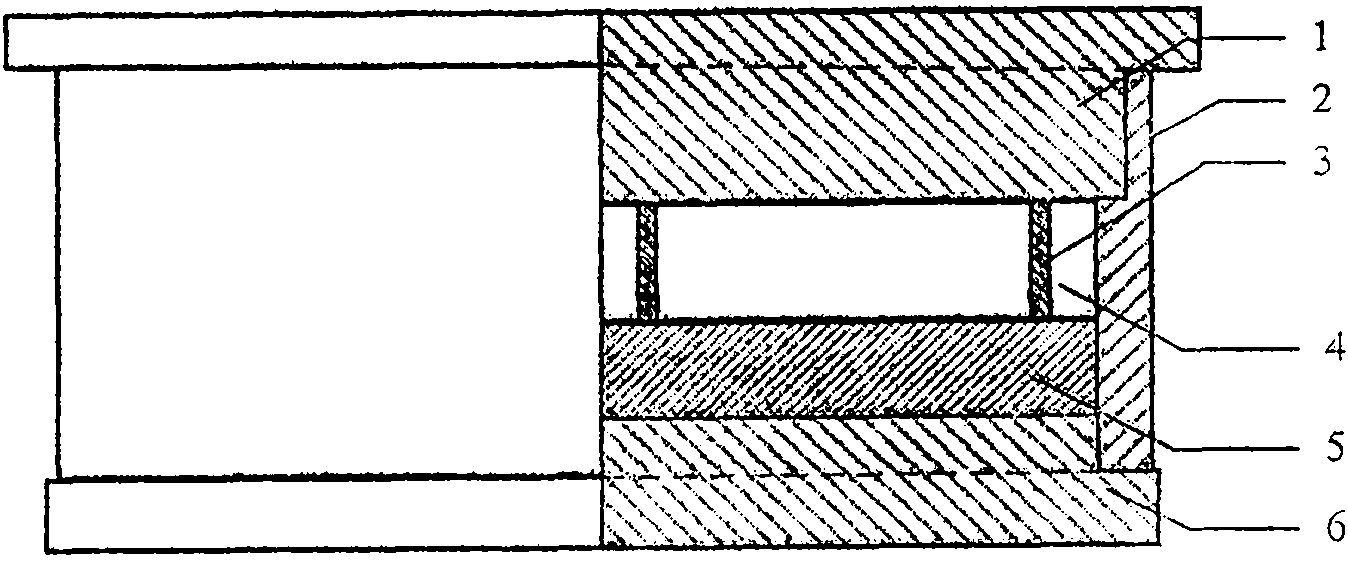

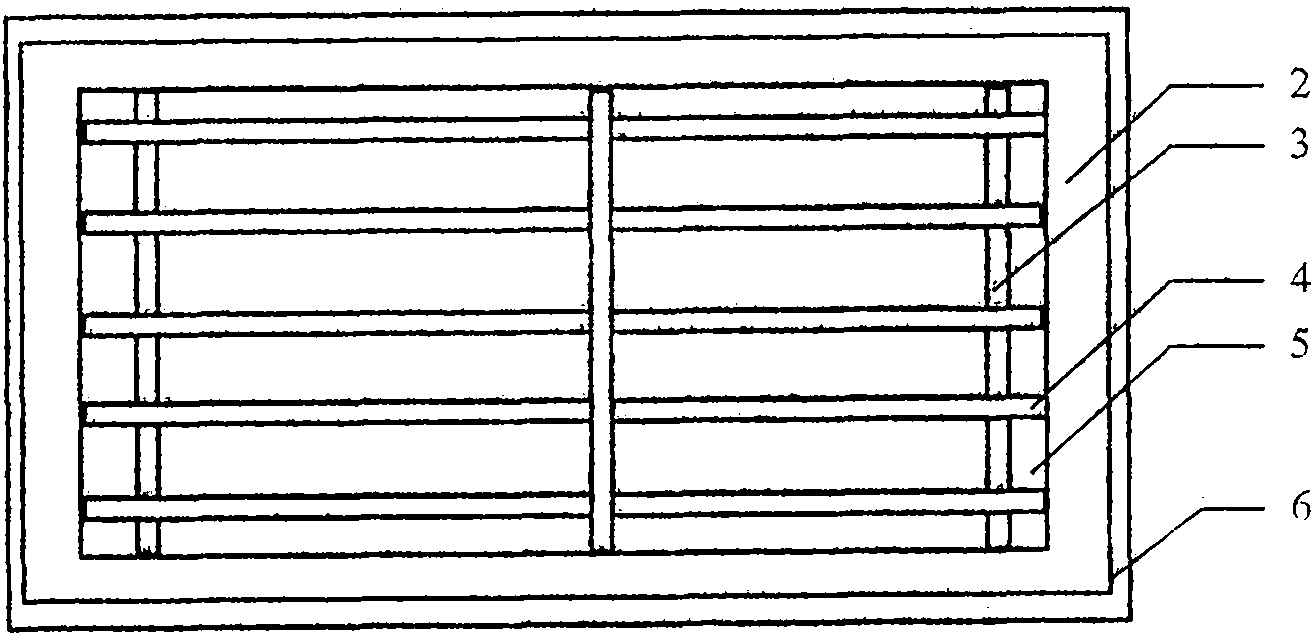

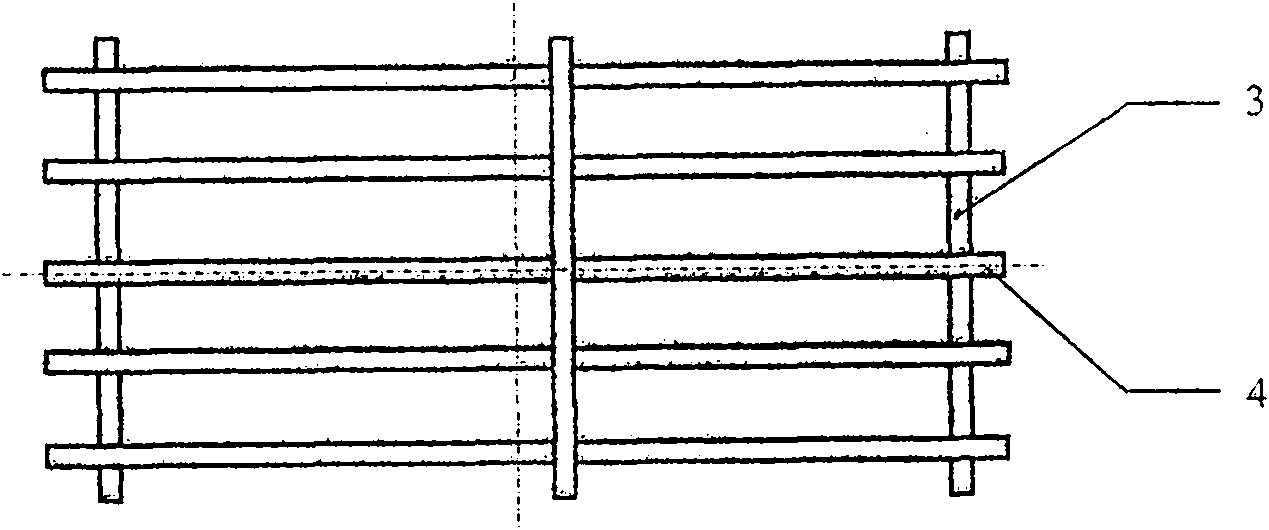

[0027] see Figure 1-15 , a polymer hot-press mold with a variable cavity, including an upper male mold 1, a female mold 2, and a lower male mold 6. The female mold 2 has a cavity that runs through up and down, and the upper and lower parts of the cavity are respectively connected to the upper male mold. 1 is matched with the lower male mold 6, and it is characterized in that: the hot pressing mold is a cuboid as a whole, and the upper male mold 1 and the lower male mold 6 are rectangular parallelepiped convex platforms; the female mold 2 is a hollow cuboid up and down, and the inner cavity The cross-section of the body is rectangular, and the upper part of the cavity has a rectangular groove that is 6-10 mm longer than each side of the cavity and 25-40 mm deep from the upper mouth of the female mold 2. It is precisely matched with the boss of the upper male mold 1, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com