Heat accumulation and energy storage graphite material for solar thermal power generation and preparation method thereof

A technology of graphite materials and heat storage materials, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of poor heat storage capacity, non-durable cost, low working temperature, etc., and achieve long service life and good mechanical properties , the effect of small elastic modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

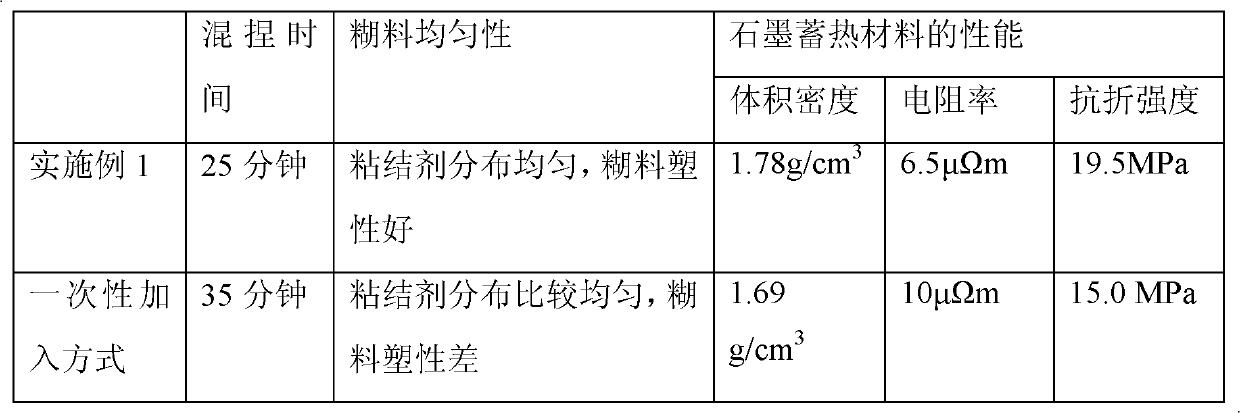

Embodiment 1

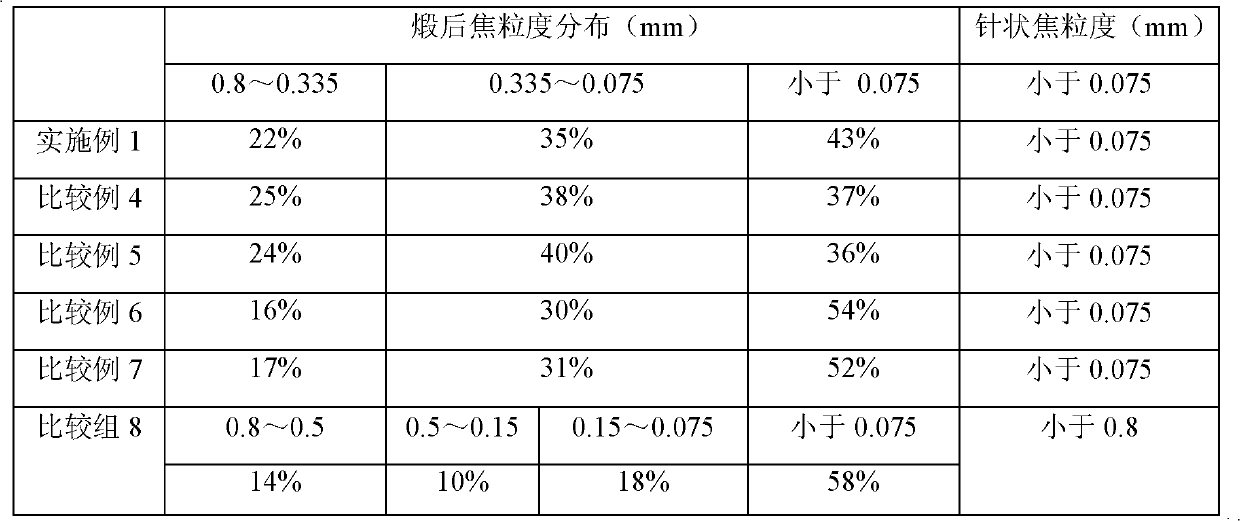

[0053] The calcined petroleum coke and needle coke are mixed according to the mass ratio (9:1), and the mixture is crushed and sieved to make three grades of pellets: 0.8-0.335mm, 0.335-0.075mm and less than 0.075mm , respectively placed in three material bins; among them: the mass percentage content of the mixture of 0.335<particle size≤0.8mm is 22%, the mass percentage content of the mixture of 0.075mm<particle size≤0.335mm is 35%, and the particle size≤0.075mm The mass percent of the mixture is 43%.

[0054] Put the above mixture into the kneading pot for dry mixing, the temperature of the kneading pot is 165°C, stir at 39.6 rpm for 30 minutes, and the temperature of the dry material is 135°C.

[0055] After the dry mixing is completed, add modified asphalt into the kneading pot, the mass percentage of dry material and modified asphalt is 75:25, wherein the modified asphalt is added in two times, and the first addition is 60% of the total modified asphalt. %, kneading with...

Embodiment 2

[0062] Proportion calcined petroleum coke and needle coke according to the mass percentage (17:3), and the mixture is crushed and sieved to make three grades of pellets: 0.8-0.335mm, 0.335-0.075mm and less than 0.075mm , respectively placed in three material bins; among them: the mass percentage content of the mixture of 0.335<particle size≤0.8mm is 18%, the mass percentage content of the mixture of 0.075mm<particle size≤0.335mm is 36%, and the particle size≤0.075mm The mass percentage of the mixture is 46%.

[0063] Put the above-mentioned mixture into the kneading pot for dry mixing, the temperature of the kneading pot is 170°C, stir at 39.6 rpm for 40 minutes, and the temperature of the dry material is 135°C.

[0064] After the dry mixing is completed, add modified asphalt into the kneading pot, the mass percentage of dry material and modified asphalt is 80:20, wherein the modified asphalt is added in two times, and the first addition is 55% of the total modified asphalt. ...

Embodiment 3

[0071] The calcined petroleum coke and needle coke are mixed according to the mass ratio (88:12), and the mixture is crushed and sieved to make three grades of pellets: 0.8-0.335mm, 0.335-0.075mm and 0.075-0mm , respectively placed in three material bins; among them: the mass percentage content of the mixture of 0.335<particle size≤0.8mm is 22%, the mass percentage content of the mixture of 0.075mm<particle size≤0.335mm is 32%, and the particle size≤0.075mm The mass percentage of the mixture is 46%.

[0072] Put the above mixture into the kneading pot for dry mixing, the temperature of the kneading pot is 175°C, stir at 39.6 rpm for 40 minutes, and the temperature of the dry material is controlled between 125°C.

[0073] After the dry mixing is completed, add modified asphalt into the kneading pot, the mass ratio of dry material and modified asphalt is 8:1, wherein the modified asphalt is added in two times, and the first addition is 45% of the total modified asphalt. %, knea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com