Polydimethylsiloxane/silicon dioxide hybrid membrane and preparation method thereof

A polydimethylsiloxane and silica technology, which is applied in the field of polydimethylsiloxane/silica hybrid membrane and preparation, achieves the effects of mild conditions, controllable microstructure and good separation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

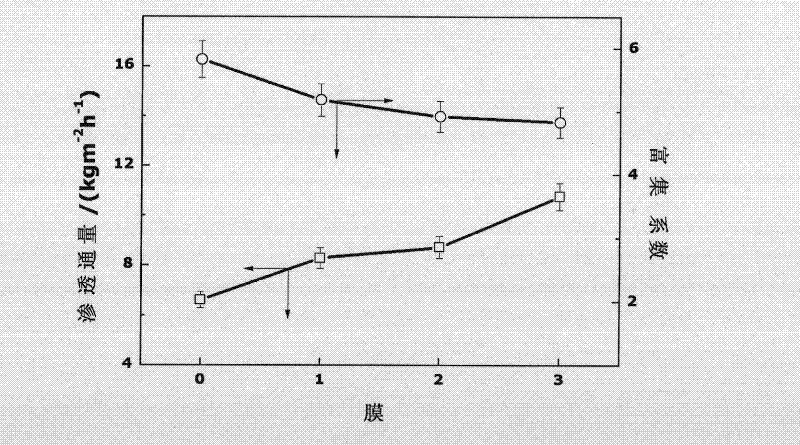

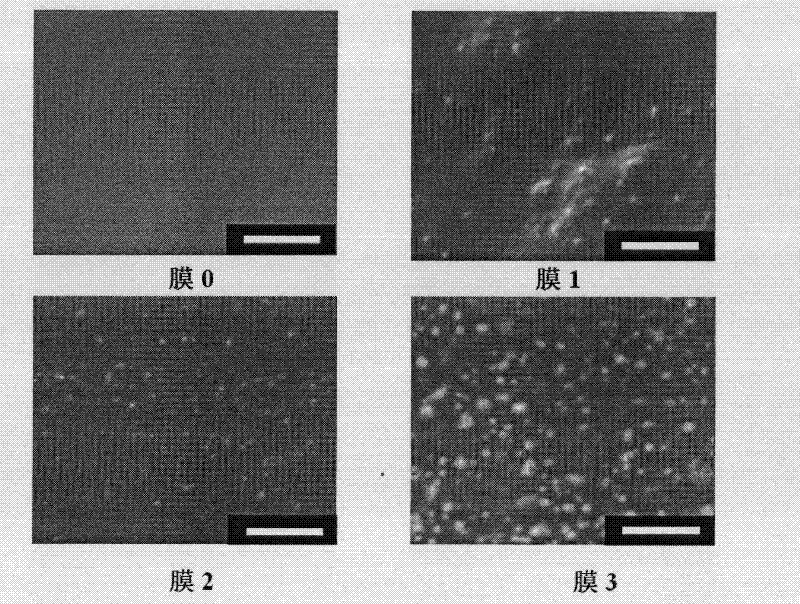

Embodiment 1

[0016] Polydimethylsiloxane (PDMS) with a viscosity of 5,000 was dissolved in n-heptane to prepare n-heptane solutions with PDMS mass concentrations of 20 wt%. Dissolve Tween 80 / Span 80 compound surfactant (mass ratio 1:1) and tetraethyl orthosilicate (TEOS) in the above-mentioned n-heptane solution at room temperature according to a certain ratio. Wherein the TEOS content is 35wt% of the PDMS mass. Prepare a Tris-HCl buffer solution with a concentration of 30mM, adjust the pH value to 7.0, and then add protamine sulfate to prepare an aqueous solution with a mass concentration of protamine sulfate (protamine sulfate) of 10mg / ml. The above protamine aqueous solution was added dropwise to the previously prepared n-heptane solution under the condition of strong mechanical stirring, the mass fraction of the protamine aqueous solution in the final mixed solution was 1.4wt%, and the protamine aqueous solution and The mass ratio of the surfactant is 0.45. Add a few drops of dibutyl...

Embodiment 2

[0018] Polydimethylsiloxane (PDMS) with a viscosity of 5,000 was dissolved in n-heptane to prepare n-heptane solutions with PDMS mass concentrations of 20 wt%. Dissolve Tween 80 / Span 80 compound surfactant (mass ratio 1:1) and tetraethyl orthosilicate (TEOS) in the above-mentioned n-heptane solution at room temperature according to a certain ratio. Wherein the TEOS content is 45wt% of the PDMS mass. A Tris-HCl buffer solution with a concentration of 30 mM was prepared, the pH value was adjusted to 7.0, and then protamine sulfate was added to prepare an aqueous solution with a mass concentration of protamine sulfate of 10 mg / ml. The above protamine aqueous solution was added dropwise to the previously prepared n-heptane solution under the condition of strong mechanical stirring, the mass fraction of the protamine aqueous solution in the final mixed solution was 1.9wt%, and the protamine aqueous solution and The mass ratio of the surfactant is 0.45. Add a few drops of dibutylt...

Embodiment 3

[0020] Polydimethylsiloxane (PDMS) with a viscosity of 5,000 was dissolved in n-heptane to prepare n-heptane solutions with PDMS mass concentrations of 20 wt%. Dissolve Tween 80 / Span 80 compound surfactant (mass ratio 1:1) and tetraethyl orthosilicate (TEOS) in the above-mentioned n-heptane solution at room temperature according to a certain ratio. Wherein the TEOS content is 60wt% of the PDMS mass. A Tris-HCl buffer solution with a concentration of 30 mM was prepared, the pH value was adjusted to 7.0, and then protamine sulfate was added to prepare an aqueous solution with a mass concentration of protamine sulfate of 10 mg / ml. The above-mentioned protamine aqueous solution is added dropwise in the previously prepared n-heptane solution under the condition of strong mechanical stirring, the mass fraction of the protamine aqueous solution in the final mixed solution is 2.4wt%, the protamine aqueous solution and the surface The mass ratio of the active agent is 0.45. Add a few...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com