Method for preparing hydrogen by cracking water by using aluminum-based material

An aluminum-based material, hydrogen technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

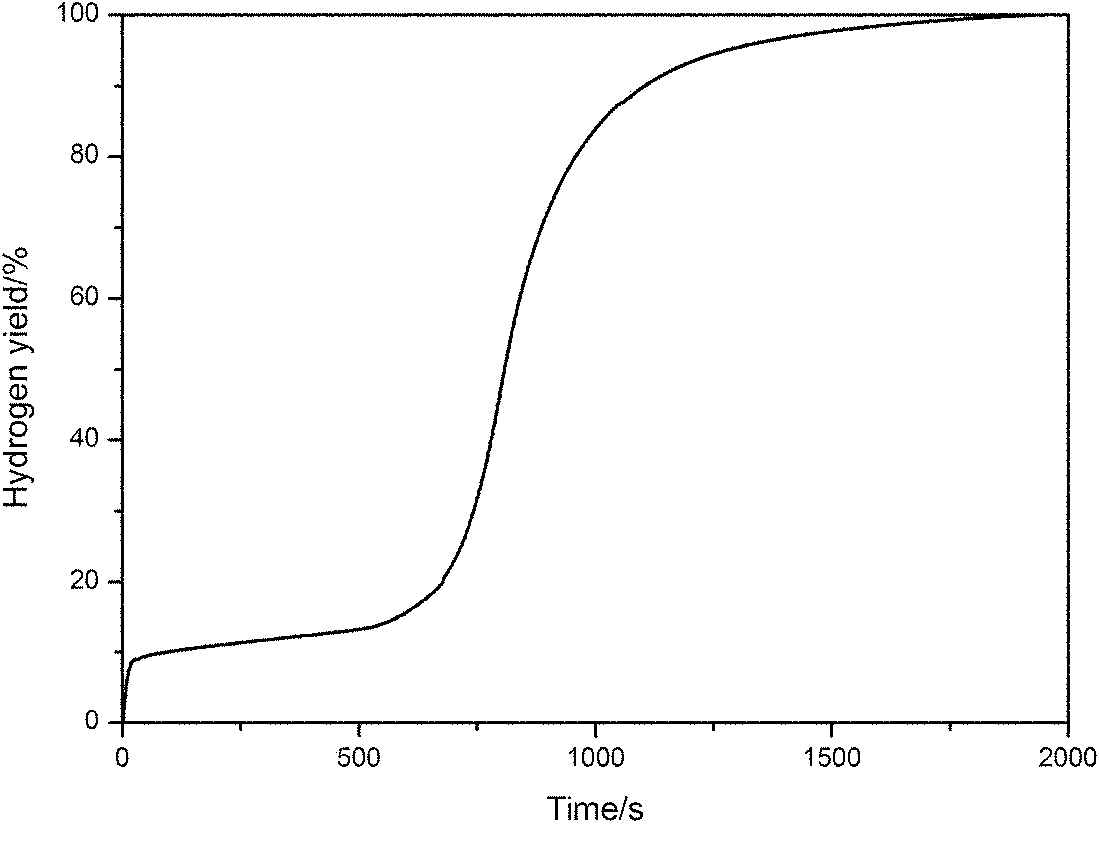

Image

Examples

Embodiment 1

[0025] 0.5g containing Na 2 O 5wt%, the aluminum base material containing NaCl 20wt% is placed in the reactor, injects 20ml again, the pure water of 30 ℃, reacts and carries out 60 minutes; Produce the quality of hydrogen discharge water by automatic weighing record balance measurement, convert into hydrogen Volume, by calculation the hydrogen yield is 98%.

Embodiment 2

[0027] 0.5g containing K 2 O 15wt%, the aluminum-based material containing KCl 15wt% is placed in the reactor, injects 20ml again, the NaCl solution of 30 ℃, and reacts for 60 minutes; Measure the mass of hydrogen discharge water by automatic weighing record balance, convert into hydrogen Volume, by calculating the hydrogen yield is 98.7%.

Embodiment 3

[0029] 0.5g containing CaO 30wt%, containing Na 2 SO 47wt% of the aluminum-based material was placed in the reactor, and then 20ml of pure water at 50°C was injected, and the reaction was carried out for 60 minutes; the mass of hydrogen generated and discharged water was measured by an automatic weighing record balance, converted into hydrogen volume, and calculated by calculating the hydrogen production The rate is 100%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com