High-speed centrifugal atomization device for flue gas treatment

A high-speed centrifugal and atomization device technology, which is applied in the direction of spraying devices, spraying devices, separation methods, etc., can solve the problems that the particle size of liquid materials cannot be effectively controlled, the number of nozzles is large, and the nozzles wear quickly, etc., to achieve flue gas treatment reaction Thorough, low residual pollutants, good atomization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

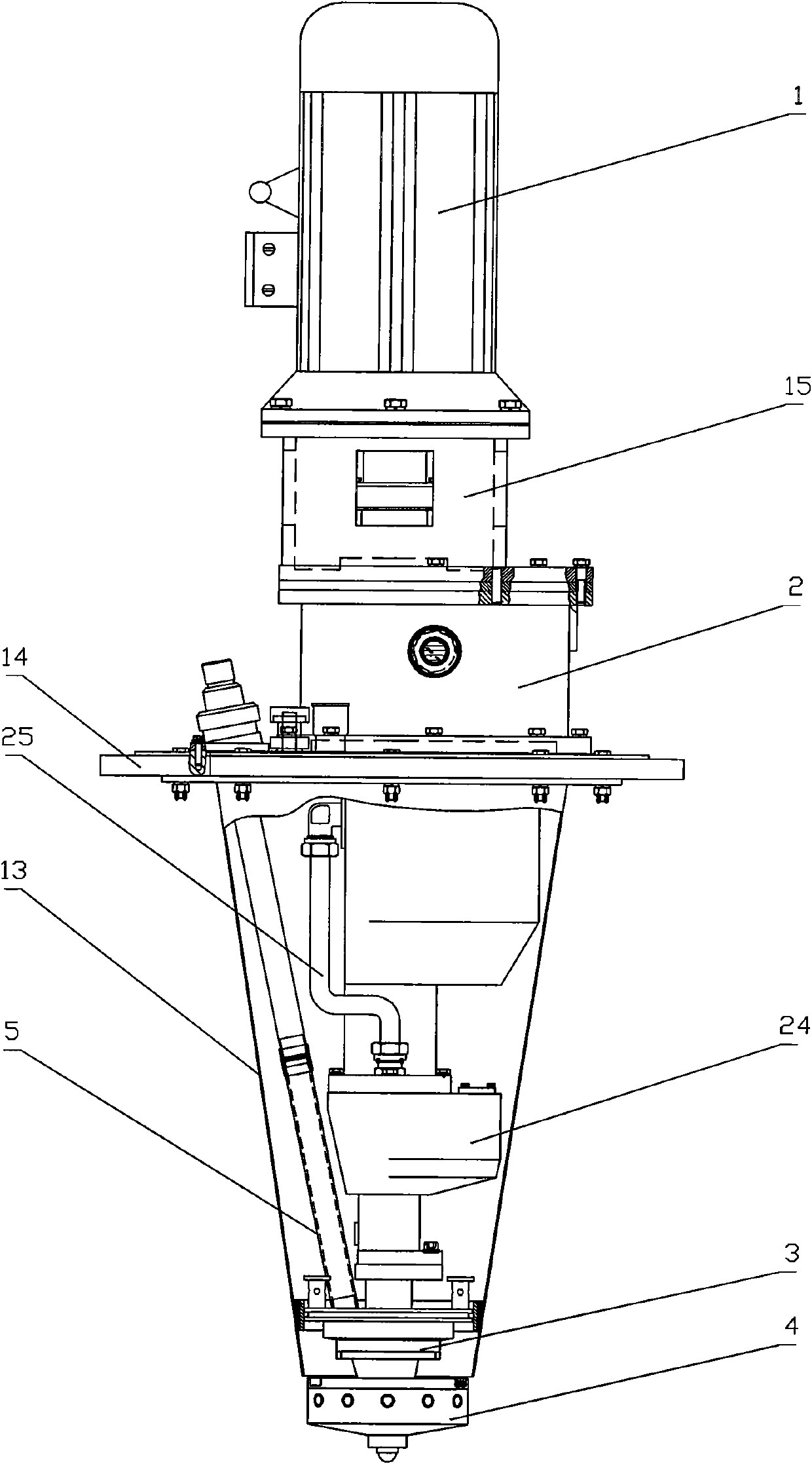

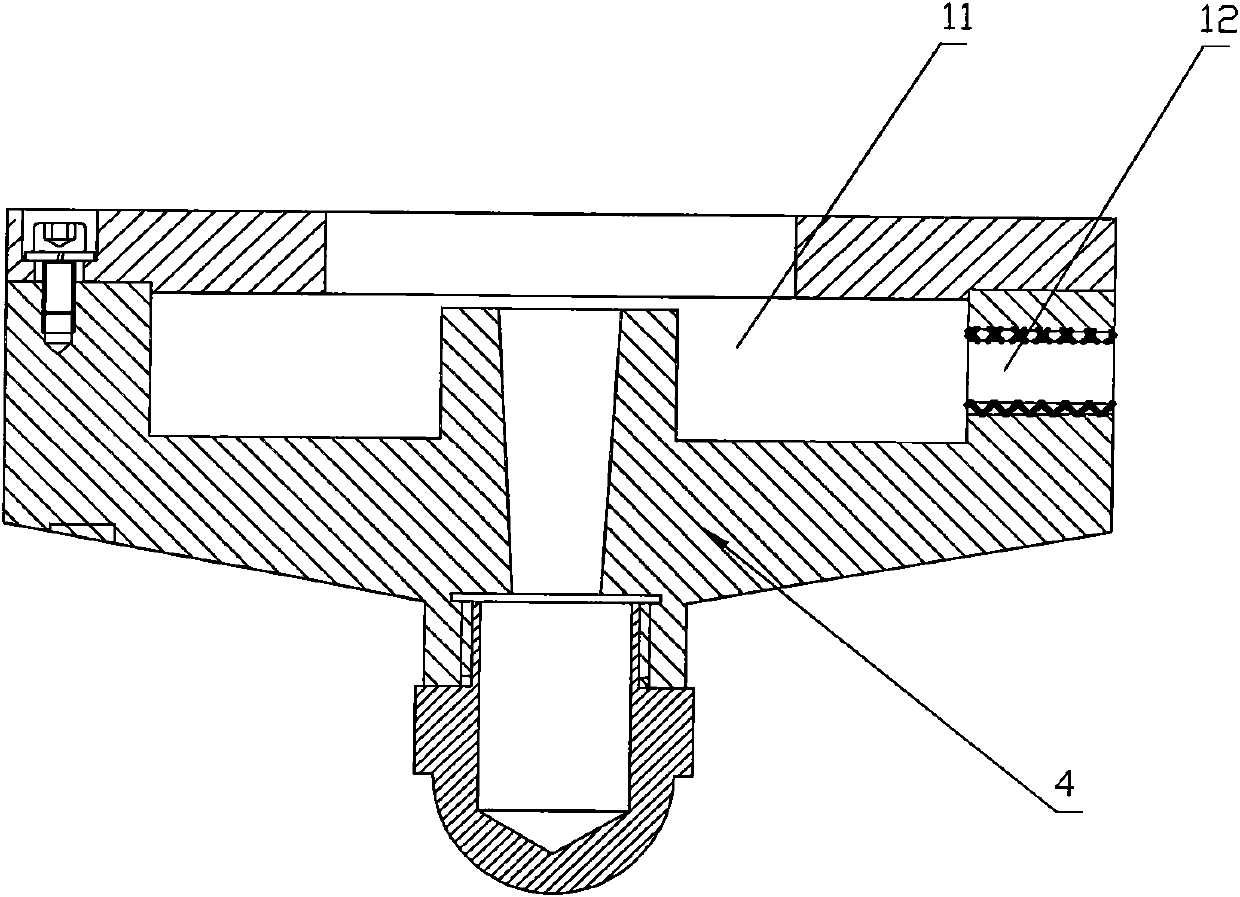

[0024] like figure 1 As shown: the high-speed centrifugal atomization device for flue gas treatment includes frequency conversion motor 1, speed increaser 2 driven by frequency conversion motor 1, distributor 3, atomization disc 4, and a device for transporting and processing liquid materials required for flue gas reaction. The feed pipe 5, the sealing cover 13 and the base 14 for fixed installation on the top of the spray absorption tower. The output shaft of the variable frequency motor 1 is connected with the power input shaft of the speed increaser 2 through an elastic pin gear coupling 15 . Frequency conversion motor 1 , elastic pin gear coupling 15 and speed increaser 2 are fixedly installed on the top of machine base 14 . The sealing cover 13 is a conical structure, and is installed on the bottom of the machine base 14 by bol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com