Rotor of high-power permanent magnet motor and permanent magnet synchronous wind-driven generator using same

A permanent magnet motor, high-power technology, used in synchronous machines, wind power generation, synchronous machine parts and other directions, can solve problems such as deformation, magnetic flux leakage, etc., to reduce harmonic content, improve utilization, and prevent irreversible demagnetization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

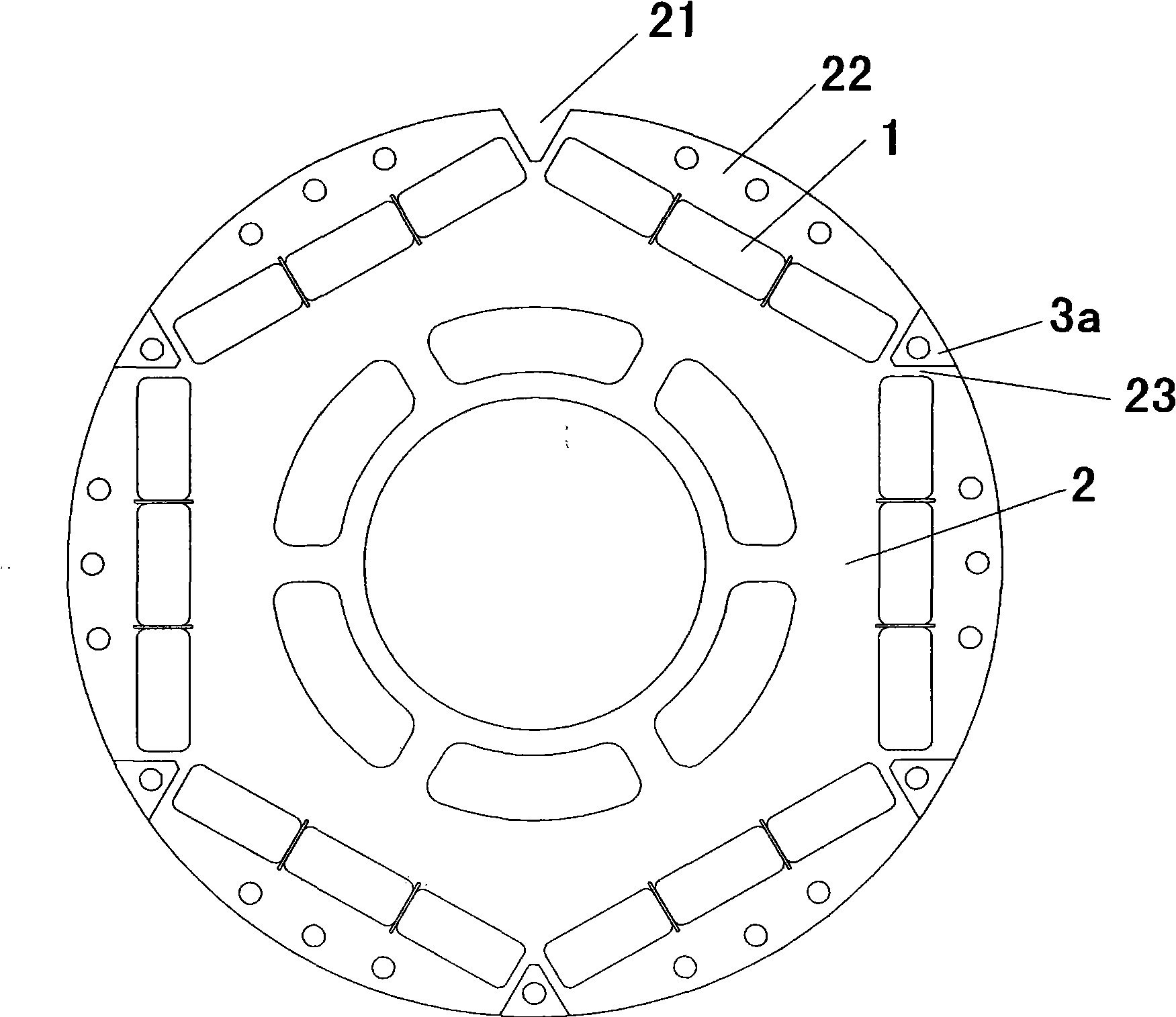

[0039] see figure 1 In the first embodiment of the permanent magnet motor rotor of the present invention, the rotor core 2 between the two adjacent poles embedded permanent magnets 1 is provided with a groove 21 along the rotor axis ( figure 1 It is a front view viewed from one end face of the rotor, so the groove is shown as a notch, and the shape of the notch is the cross-sectional shape of the groove), and the filler 3a with the same cross-sectional shape as the groove 21 is arranged in the groove 21.

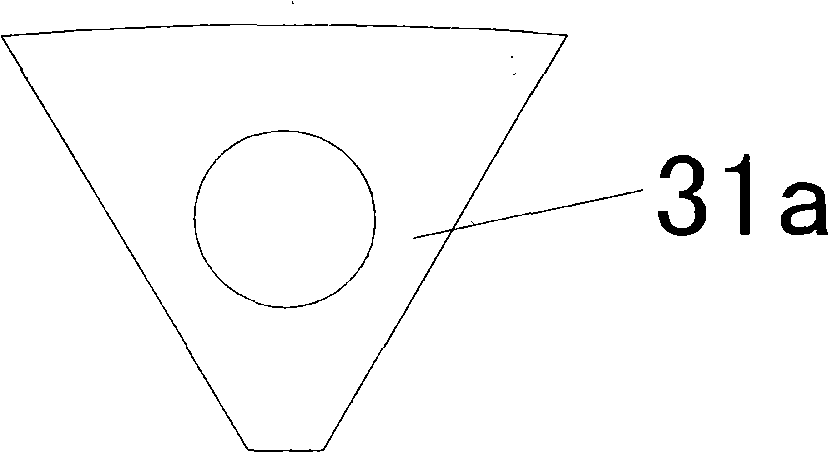

[0040] see figure 2 The filling body 3a is only composed of a magnetic isolation part 31a extending from the outer circumference of the rotor to the adjacent two-pole permanent magnet 1, and the entire filling body 3a is made of non-magnetic and non-conductive materials, so that it The magnetic separation part 31a between the permanent magnets 1 of two poles makes the magnetic field of the permanent magnets 1 between adjacent two poles not directly connected, which can avo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com