Combined type water knockout vessel

A water separator and combined technology, applied in heating methods, hot water central heating systems, lighting and heating equipment, etc., can solve the problem that plastics and inserts are prone to leakage, only the entire water separator can be replaced, and distribution production Trouble and other problems, to achieve the effect of convenient production and distribution, good sealing, and quick installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in further detail by the following examples.

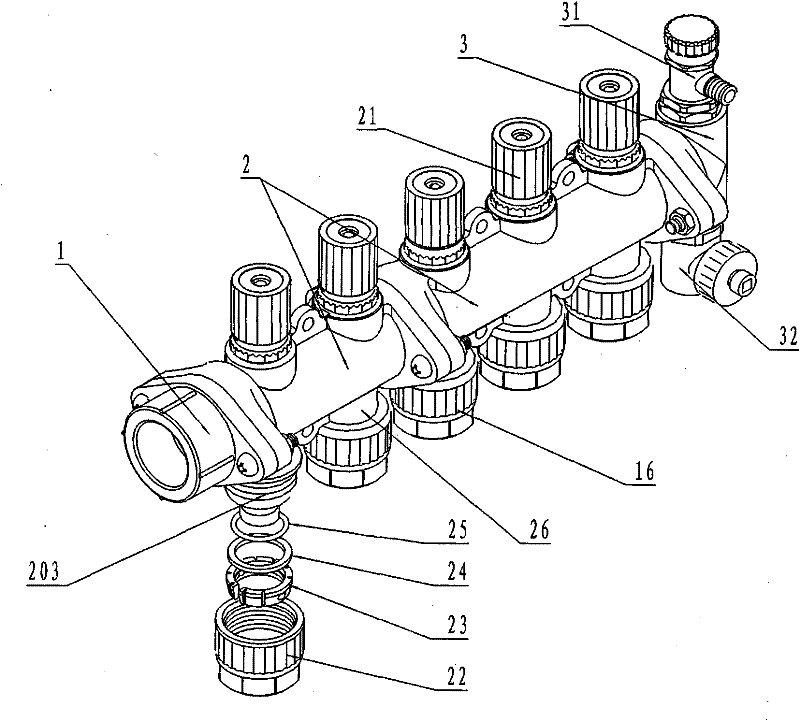

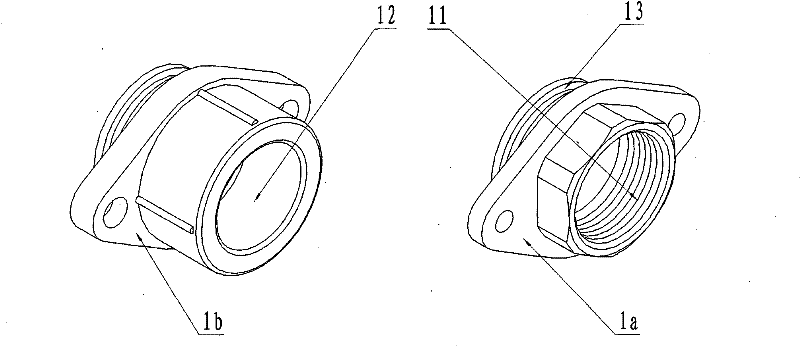

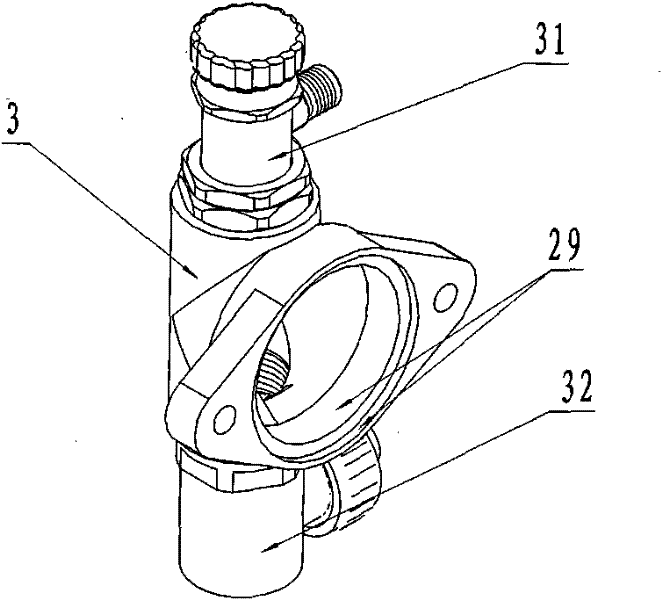

[0019] see Figure 1-Figure 6 As shown, a combined water separator consists of a main body 2 with a built-in water channel, an inlet end 1, and a tail end 3 connected by an elliptical flange to form an integral structure. 3. The main body 2 is composed of multiple segmented main bodies. The upper part of each segmented main body is equipped with 2-3 sets of stop valves 21, the lower part of each segmented main body is equipped with 2-3 sets of outlet pipe joints 16, and the tail end 3 is equipped with Exhaust valve 31 and drain valve 32. The interface provided on the main body of each segment and the corresponding water outlet 26 are integrally formed by injection molding. The water outlet 26 is provided with a section of external thread 203, a counterbore 201 and a groove 202. On the said water outlet 26, O Type sealing ring 25, flat gasket 24, C-shaped ring 23 and nut 22 constitute out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com