Fracture-cave type carbonate reservoir waterflooding oil replacement recovery method

A technology of water injection for oil replacement and production method, which is applied in the direction of production fluid, earthwork drilling and production, wellbore/well parts, etc., and can solve problems such as low awareness, low economic benefit, and recovery rate of less than 10%

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

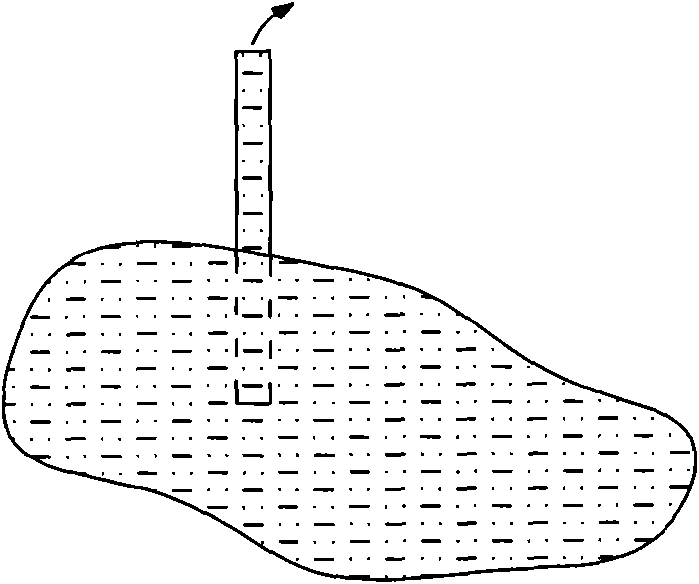

Image

Examples

Embodiment Construction

[0022] In the present invention, at first oil reservoirs are divided into different fracture-vuggy units, and natural energy and reserve scale are selected to classify fracture-vuggy units in two levels. According to natural energy 0.2≤Dpr<0.8, Npr=10-30, fracture-vuggy units can be The unit is divided into type I. According to the natural energy 0.8≤Dpr<2.5, Npr=2-10, the fractured-vuggy unit can be divided into type II. According to the natural energy Dpr≥2.5, Npr<2, the fractured-vuggy unit can be divided into III Type I fracture-vuggy unit reservoirs have abundant natural energy and well-developed water bodies. During the development process, the water cut of oil wells rises rapidly and the production declines greatly. Type II fracture-cavity units have certain natural energy, and the water cut in oil wells increases, while the energy decreases, resulting in a rapid decline in production. Type III fracture-vuggy units have insufficient natural energy, oil wells show deplet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com