Industrialized method for preparing 2-mercaptopyridine

A technology of mercaptopyridine and chloropyridine, applied in the field of organic chemical synthesis, can solve the problems of high price, long synthesis steps, harsh conditions, etc., and achieves the effects of solving industrialized production problems, simple and convenient production process, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

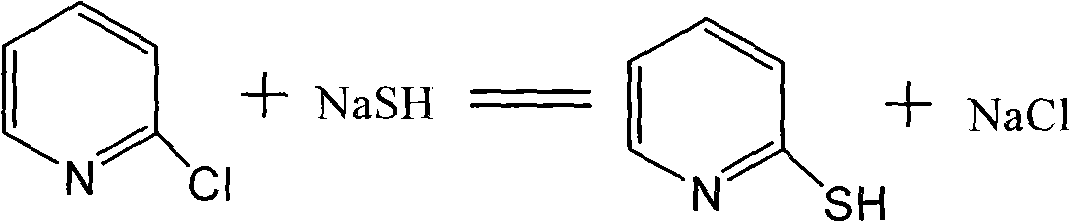

Problems solved by technology

Method used

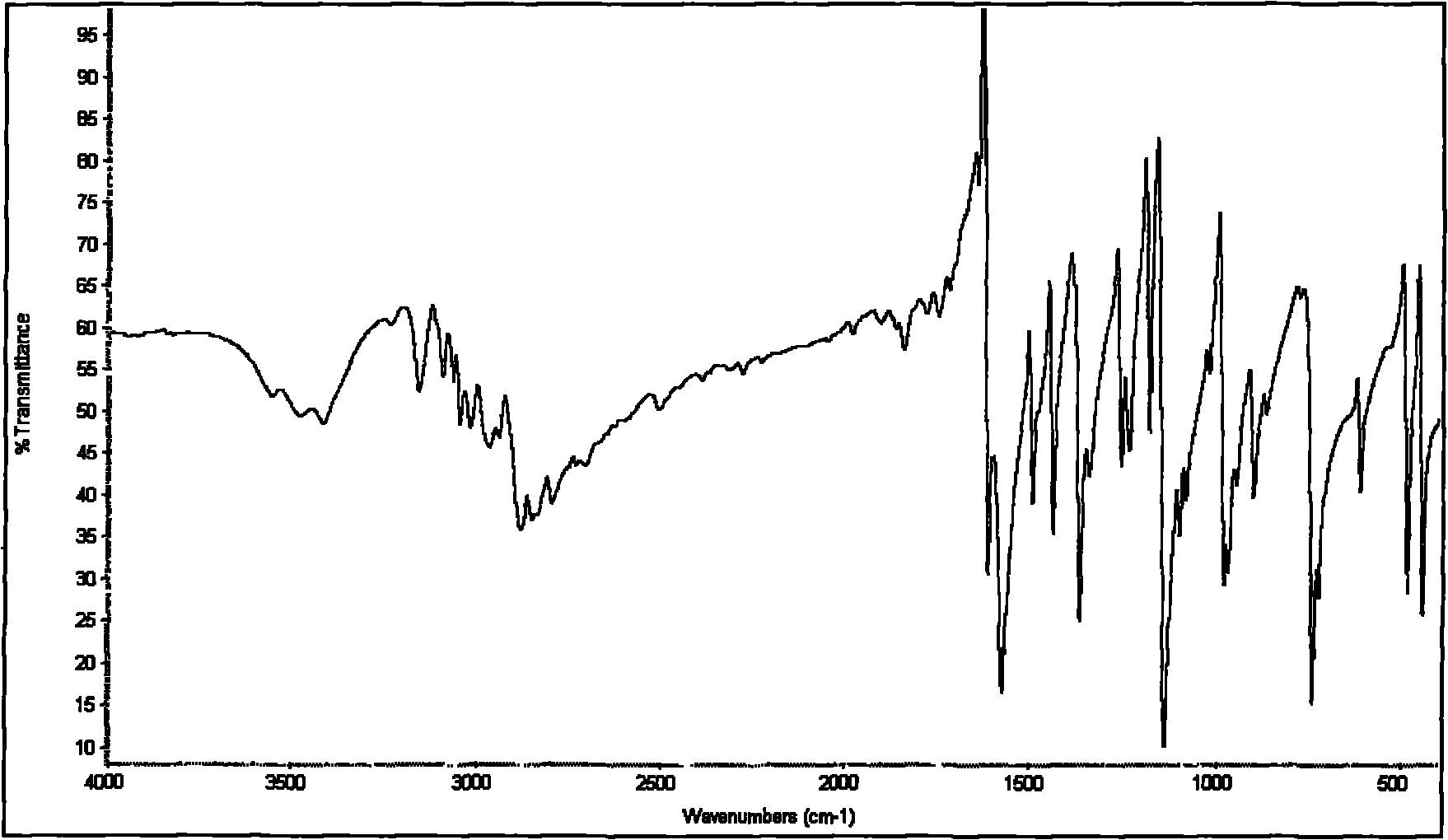

Image

Examples

Embodiment 1

[0025] Add 135kg of anhydrous sodium hydrosulfide (with a content above 99%) and 300kg of ethylene glycol into a conical reaction kettle equipped with a stirrer, a thermometer, a reflux device, a distillation device, a heating device and a feeding device, start stirring, and close the distillation device, open the reflux device, heat to 120°C, add 60kg of 2-chloropyridine to the feeding port, after 2 hours, add 60kg of 2-chloropyridine for the second time, and after another 2 hours, add 60kg of 2-chloropyridine for the third time Pyridine, after 2 hours, add 50kg2-chloropyridine again, add 230kg altogether, 2-chloropyridine, react after 18 hours, open distillation device, close reflux device, distill off solvent, add 200kg distilled water, temperature is down to room temperature, use dilute Adjust the pH value to 6-7 with hydrochloric acid, crystals are precipitated, add chloroform for extraction, use 100kg chloroform for extraction each time, extract three times in total, coll...

Embodiment 2

[0027] Anhydrous sodium hydrosulfide (content is more than 99%) 160kg and 400kg propylene glycol are joined in the conical reaction kettle that stirrer, thermometer, reflux device, distillation unit, heating unit feeding device are housed, start stirring, close distillation unit, Open the reflux device, heat to 160°C, add 60kg 2-chloropyridine at the feed port, after 2 hours, add 60kg, 2-chloropyridine for the second time, and after 2 hours, add 60kg, 2-chloropyridine for the third time, After 2 hours, add 50kg again, 2-chloropyridine, add 230kg altogether, 2-chloropyridine, react after 12 hours, open distillation device, close reflux device, distill off solvent, add 200kg distilled water, temperature is down to room temperature, use dilute Adjust the pH value to 5 with hydrochloric acid, crystals are precipitated, add toluene for extraction, use 100kg of toluene each time for extraction, and extract three times in total, collect the extract to the distillation pot, distill and...

Embodiment 3

[0029] Add 170kg of anhydrous sodium hydrosulfide (content above 99%), 400kg of mixed solution of cyclohexanol and ethylene glycol (mass ratio is 1:1) to the tank equipped with agitator, thermometer, reflux device, distillation device and heating device. In the conical reactor of the feeding device, start stirring, close the distillation device, open the reflux device, heat to 120°C, add 60kg of 2-chloropyridine to the feeding port, and after 2 hours, add 60kg of 2-chloropyridine for the second time After 2 hours, add 60kg, 2-chloropyridine for the third time, after 2 hours, add 50kg, 2-chloropyridine, add 230kg, 2-chloropyridine altogether, after reacting for 14 hours, open the distillation unit, close the reflux device, remove the solvent by distillation, add 250kg of distilled water, adjust the pH value to 6-7 with dilute acetic acid, crystals are precipitated, add toluene for extraction, use 100kg of toluene each time for extraction, and extract three times in total, collec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com