Technology for preparing barium sulfate by witherite

A technology of witherite and barium sulfate, which is applied in the field of barium sulfate preparation technology, can solve the problems of high cost, complicated process, high impurity content of finished products, etc., and achieve the effects of reducing raw material consumption, huge economic benefits, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

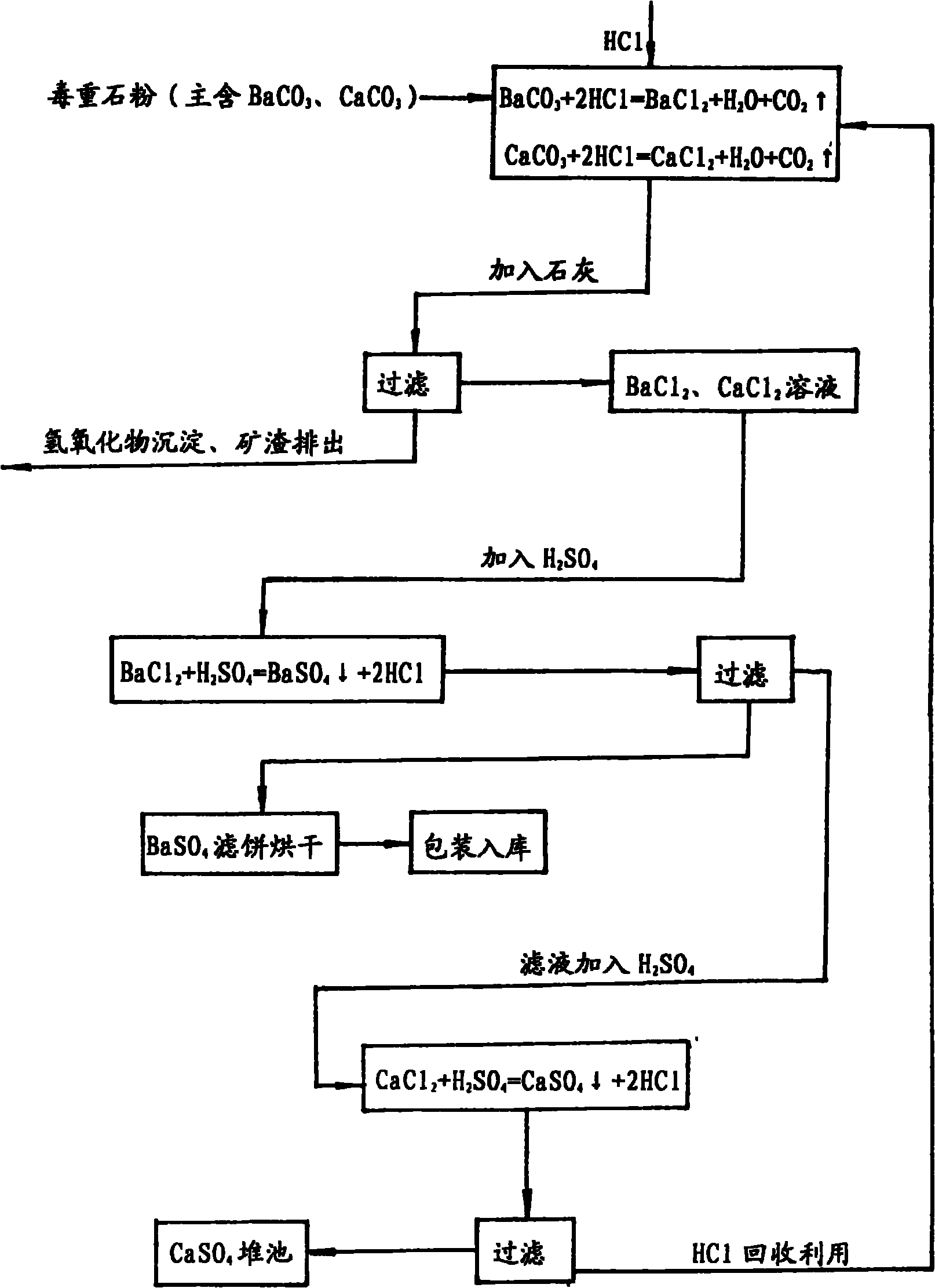

[0013] Such as figure 1 As shown, 1000Kg of witherite powder is mixed with 2306Kg of 15% hydrochloric acid to obtain a solution containing 718Kg of barium chloride and 144Kg of calcium chloride. Lime is added to the resulting solution to adjust the pH value to 10.5, so that the Fe in the solution 3+ , Mg 2+ 、Al 3+ , Mn 2+ All the heavy metal ions and OH in lime - Combined to generate hydroxide precipitates, filter and separate, remove insoluble impurities including hydroxide precipitates and slag, and obtain Ba-containing 2+ , Ca 2+ The solution, that is, to obtain a solution containing barium chloride and calcium chloride, according to the Ba in the solution 2+ content, that is, the content of barium chloride, using the huge difference between the solubility product of calcium phosphate and the solubility product of barium sulfate, adding 346Kg95% sulfuric acid, all the barium chloride in the solution reacts preferentially with the added sulfuric acid, so that the Ba 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com