Vibration pickup microphone

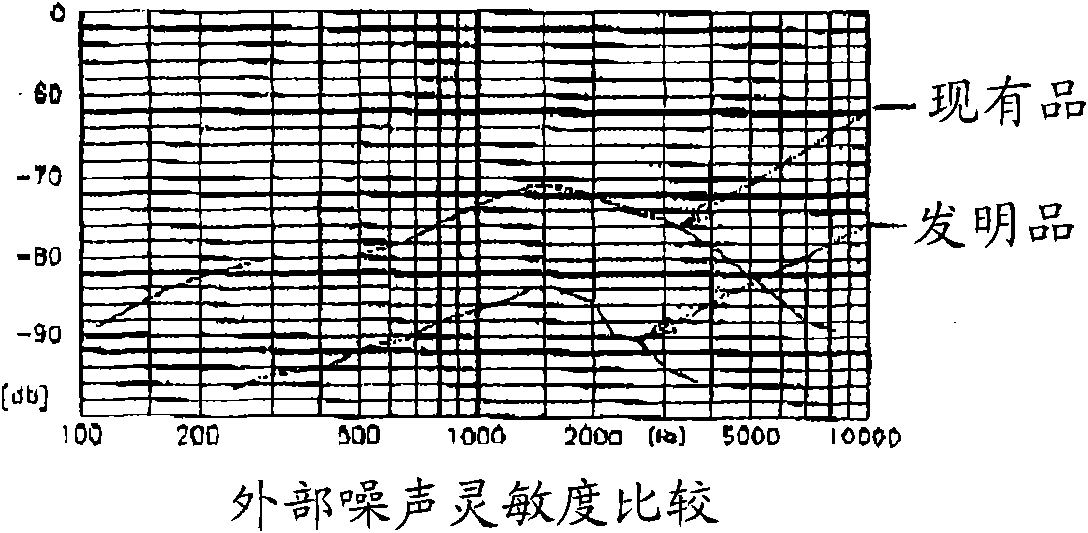

A microphone and secondary vibration technology, applied in the field of vibration pickup microphones, can solve problems such as enlarged structure, intolerance to mechanical vibration, and inability to ensure S/N, etc., to achieve improved noise characteristics, high-quality voice transmission and reception Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

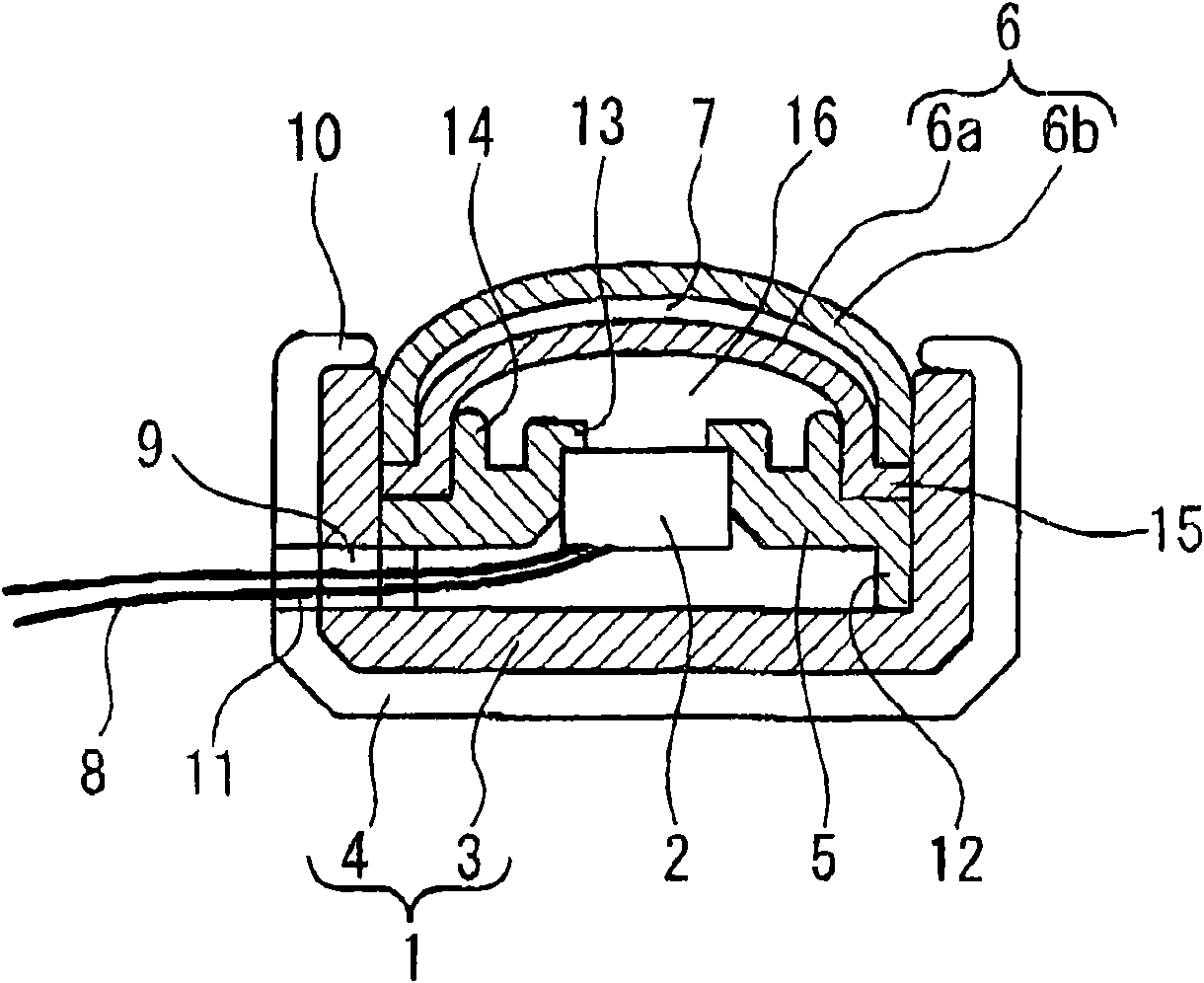

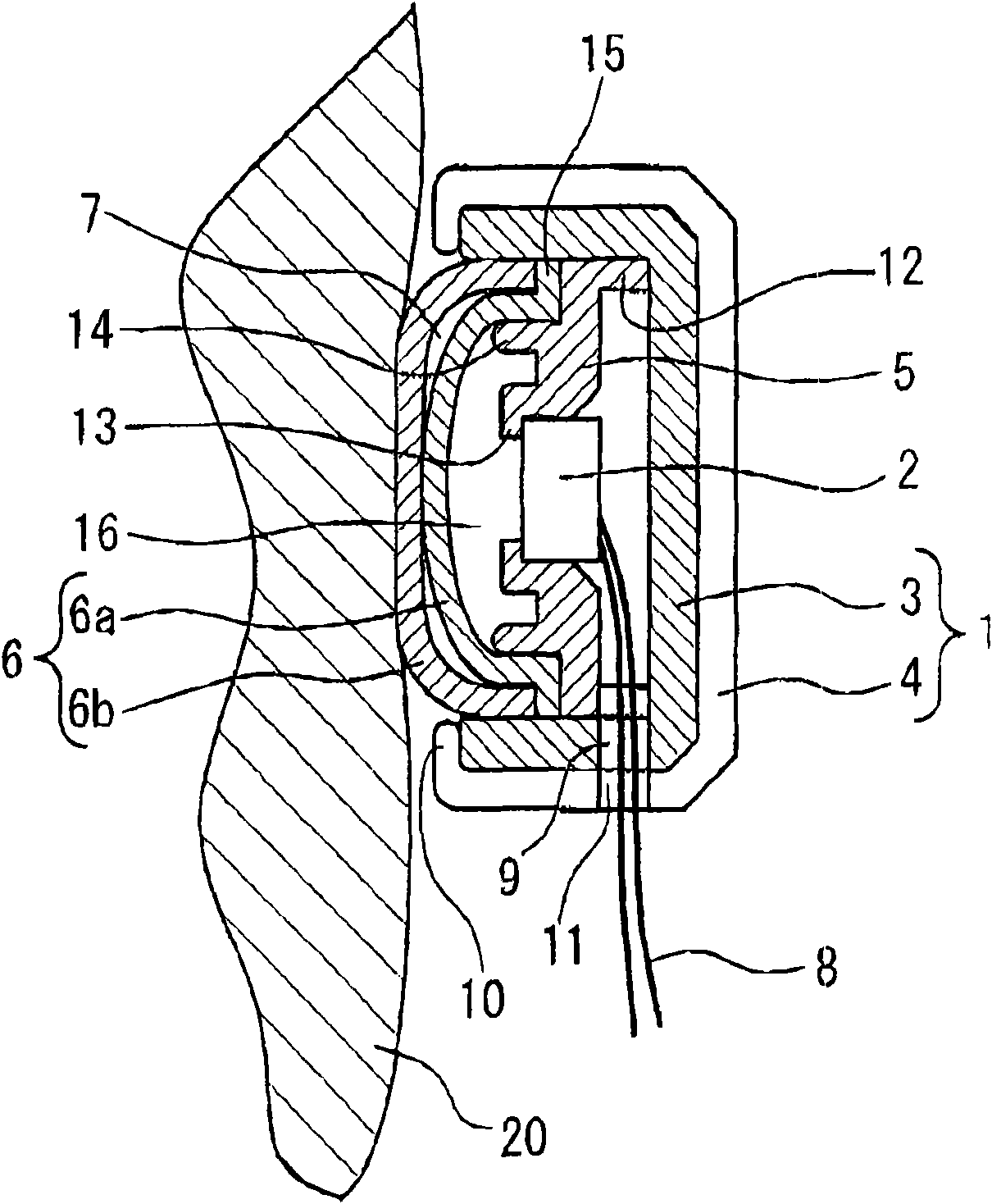

[0025] The best mode for carrying out the present invention will be described with reference to the drawings. The vibration pickup microphone of the present invention is provided with: housing 1, is arranged on the human body abutting surface of the receiver etc. that is provided with vibration pickup microphone; Microphone unit 2, is arranged in housing 1; The microphone unit 2 is supported.

[0026] The casing 1 is composed of a case 3 for accommodating a microphone holder 5 , and a cover 4 covering the case 3 . A microphone holder 5 for supporting the microphone unit 2 is embedded in the case 3 , and a multilayer diaphragm 6 is arranged to cover the upper surface of the microphone holder 5 . The multilayer diaphragm may be flat, but it is preferably dome-shaped.

[0027] The inventors of the present invention initially invented a structure in which a single-layer diaphragm is used instead of the above-mentioned multi-layer diaphragm 6 . However, in the case of using this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com