Electrical junction box

A technology for electrical junction boxes and electrical components, applied in the direction of circuits, electrical components, circuits or fluid pipelines, etc., can solve the problems of large-scale electrical junction boxes, difficult to obtain space, heat generation, etc., to improve space efficiency and suppress water splashing , Effective heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Referring now to the drawings, an exemplary embodiment of an electrical junction box will be described below.

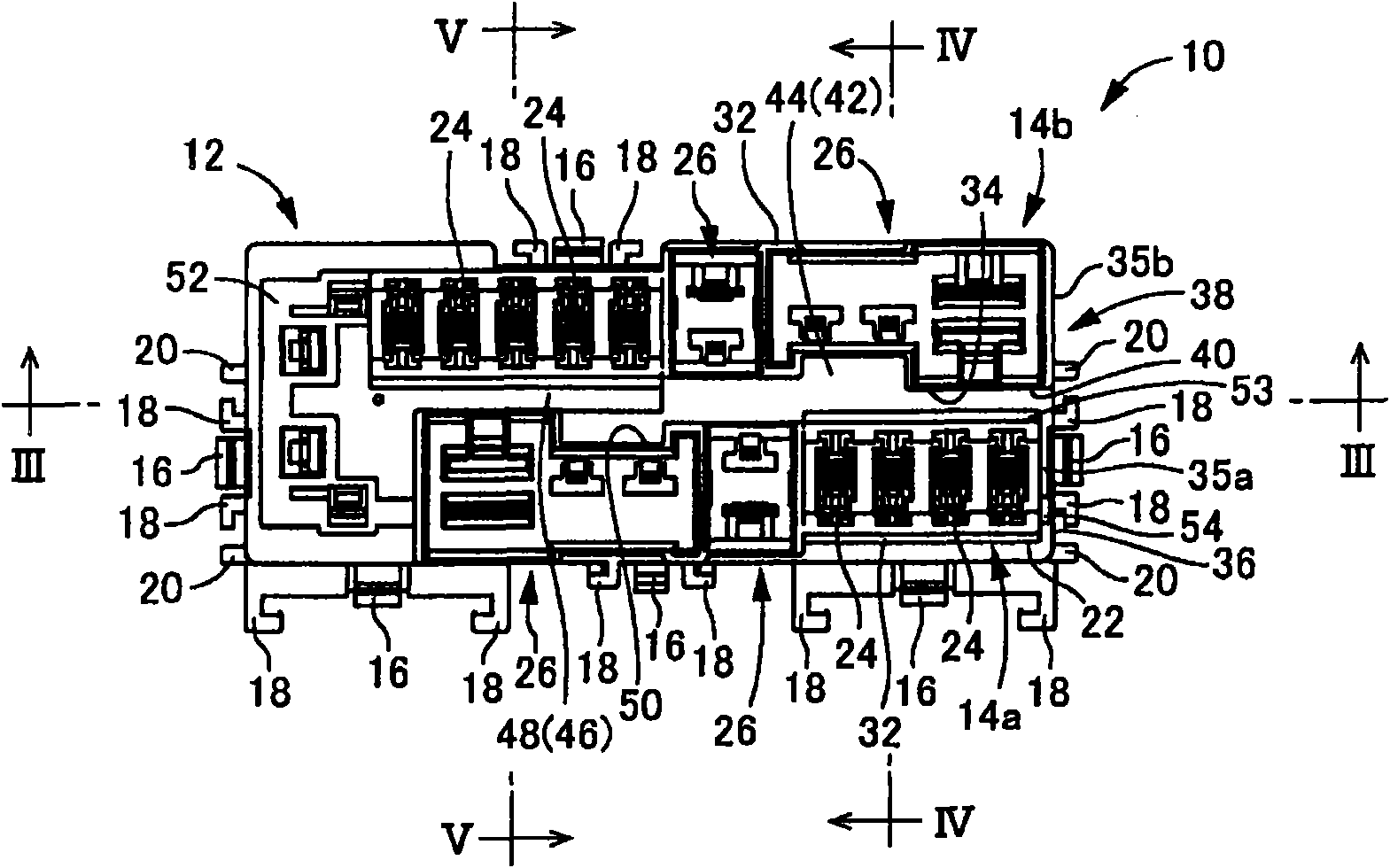

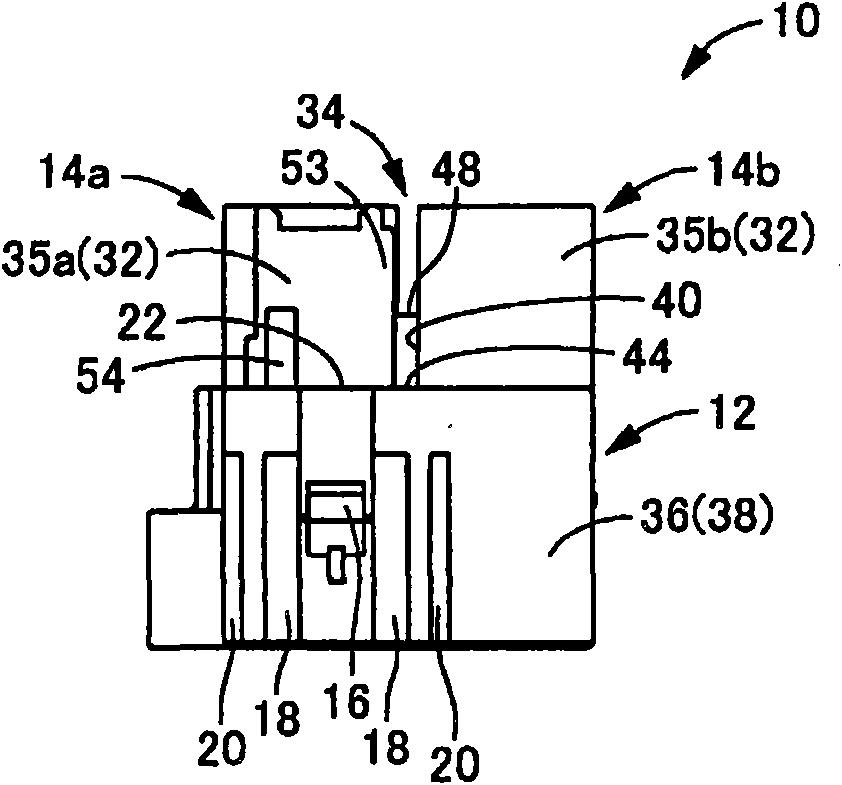

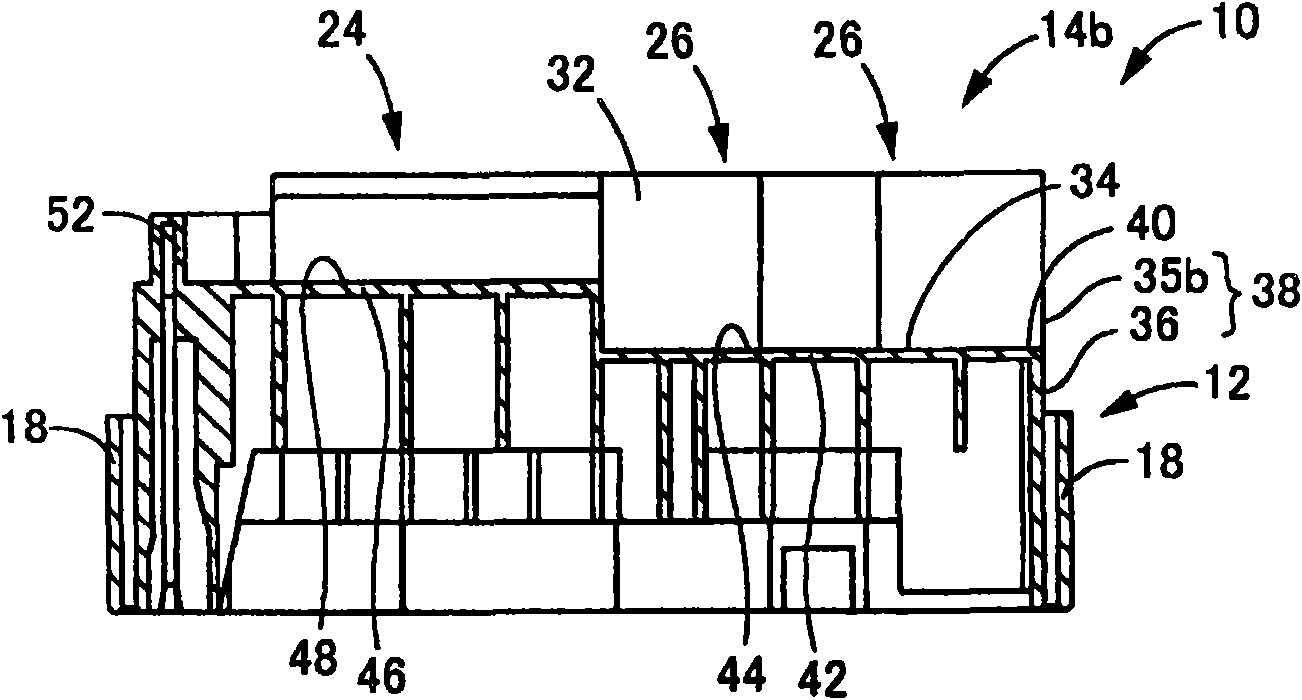

[0025] first, Figure 1-5 One embodiment of a fuse box 10 is shown, which is an example of an electrical junction box according to an exemplary embodiment. The fuse box 10 may be formed as a cuboid block made of synthetic resin. Specifically, the fuse box 10 may include a cuboid block-shaped main body 12 , a first electrical component mounting unit 14 a, and a second electrical component mounting unit 14 b. The first and second electrical component mounting portion units 14 a and 14 b protrude upward from the main body 12 .

[0026] The main body 12 may be provided with a plurality of locking pawls 16 at appropriate positions on the outer peripheral surface. On two opposite outer sides of each locking pawl 16, guide ribs 18 may be provided so that the guide ribs 18 are along the assembly direction of the cover 60 described later ( figure 2 in the up and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com