Upper sample loader

A sample carrier and sample loading technology, applied in the field of material/device performance testing, can solve problems such as unfavorable data analysis and exploration of related laws, affecting research efficiency and research quality, and intricate test results, so as to improve R&D efficiency and control The effect of convenience, ensuring controllability and parallelism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation of the present invention will be further described below in conjunction with the drawings, but the implementation and protection scope of the present invention is not limited to this.

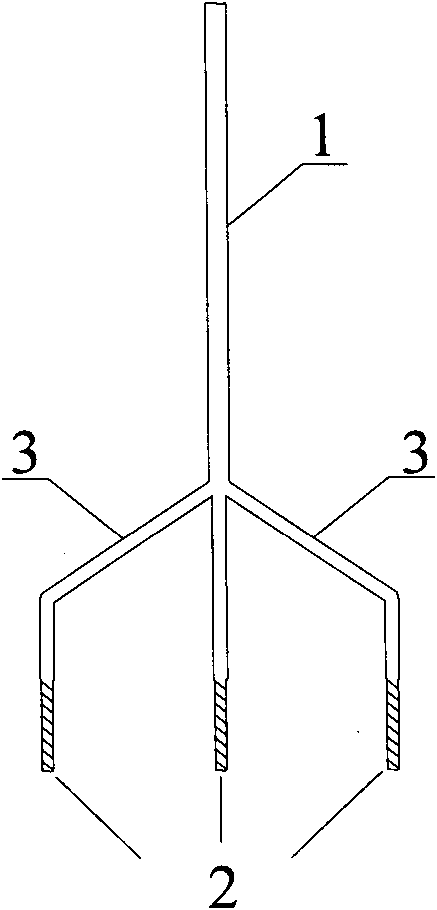

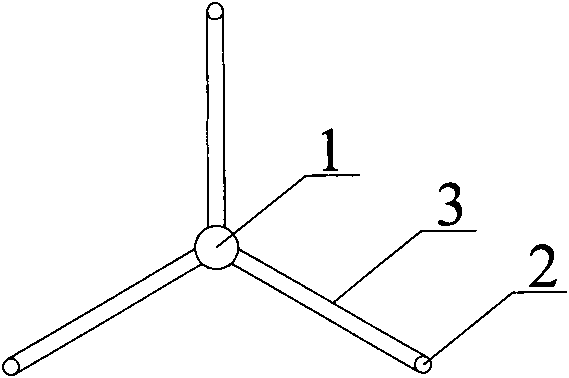

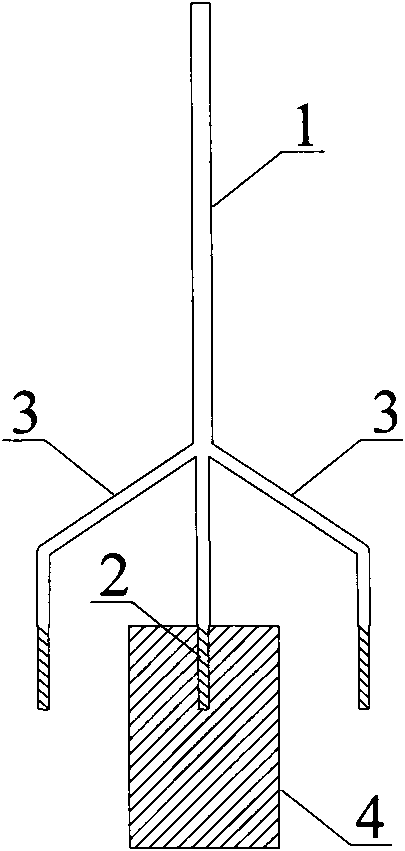

[0017] Such as figure 1 , figure 2 As shown, the upper sample loading device involved in the present invention is composed of a functional axis 1, three or more sample loading heads 2, and the same number of bridges 3 as the sample loading heads 2. One end of the connecting bridge 3 is connected with the lower end of the functional shaft 1, and the other end is connected with the upper end of the sample loading head 2, and there is a one-to-one correspondence between the sample loading head 2 and the connecting bridge 3. The functional shaft 1 and the sample loading head 2 are both cylindrical. The axis of the sample loading head 2 and the axis of the functional shaft 1 are parallel to each other. The sample loading head 2 has the same size, and its free ends a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com