Device and method for simulating generation of gas hydrate and measuring physical property parameters thereof

A technology for hydrate formation and physical property parameters, which is applied in the preparation of test samples and the analysis of fluids using acoustic/ultrasonic/infrasonic waves. Compound detection and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

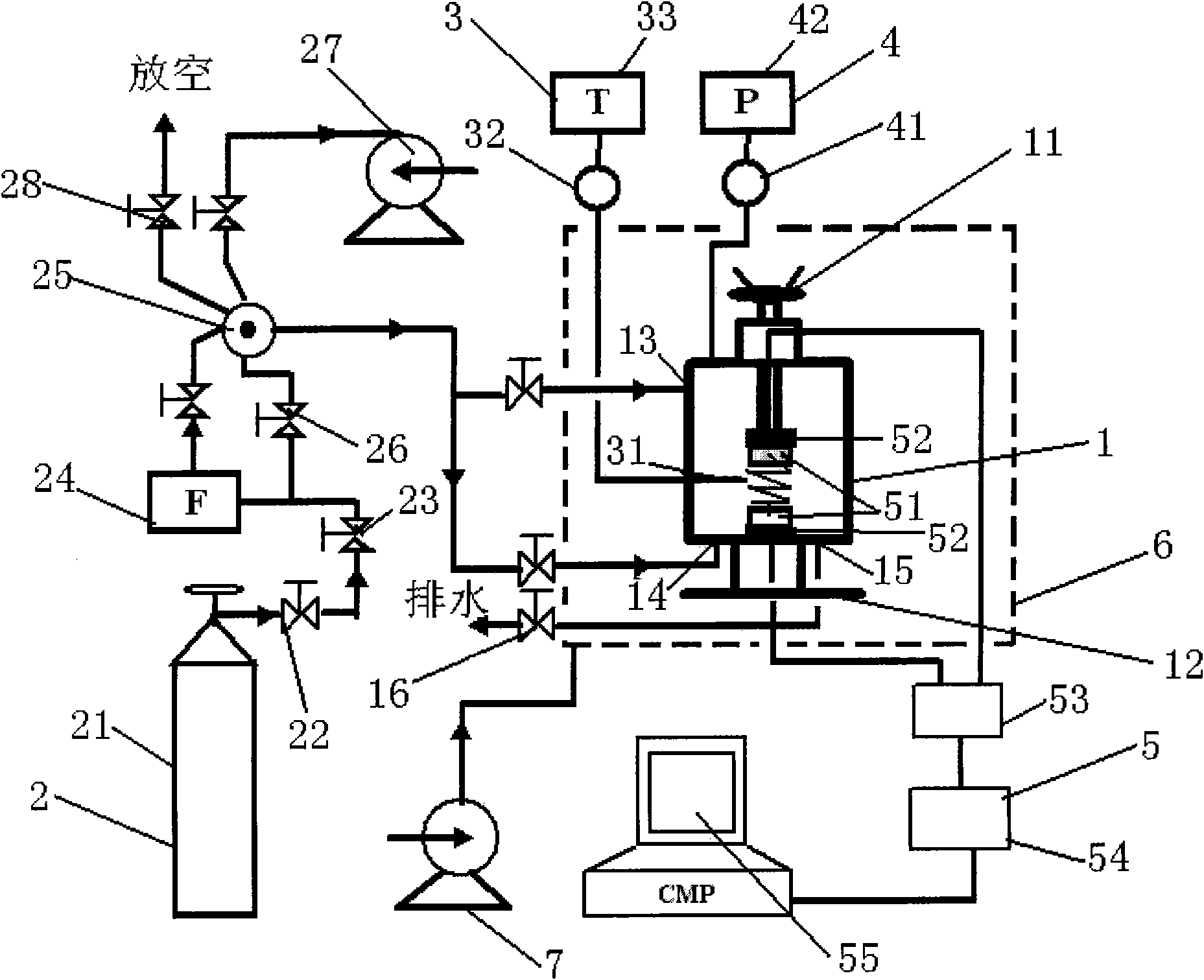

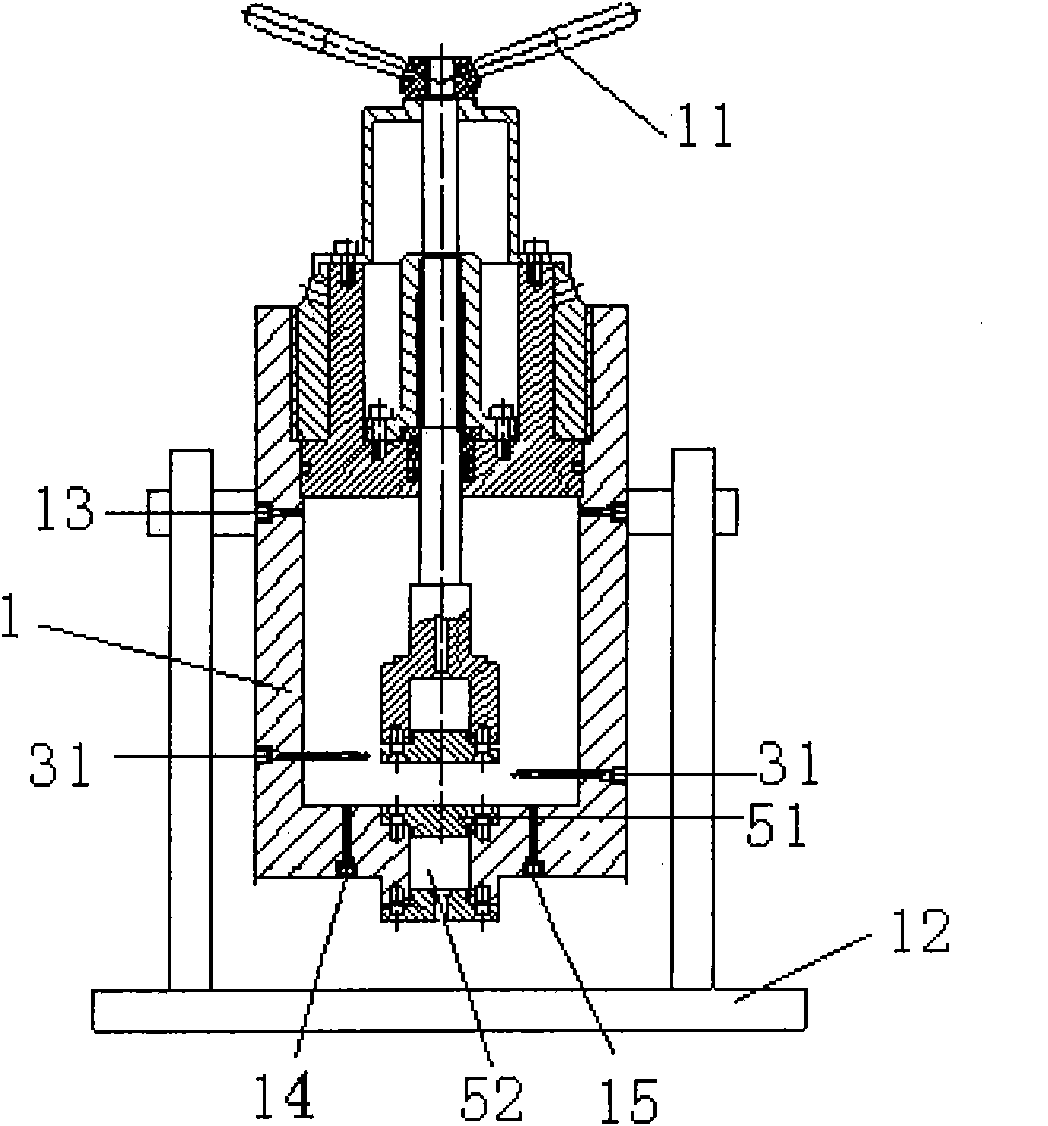

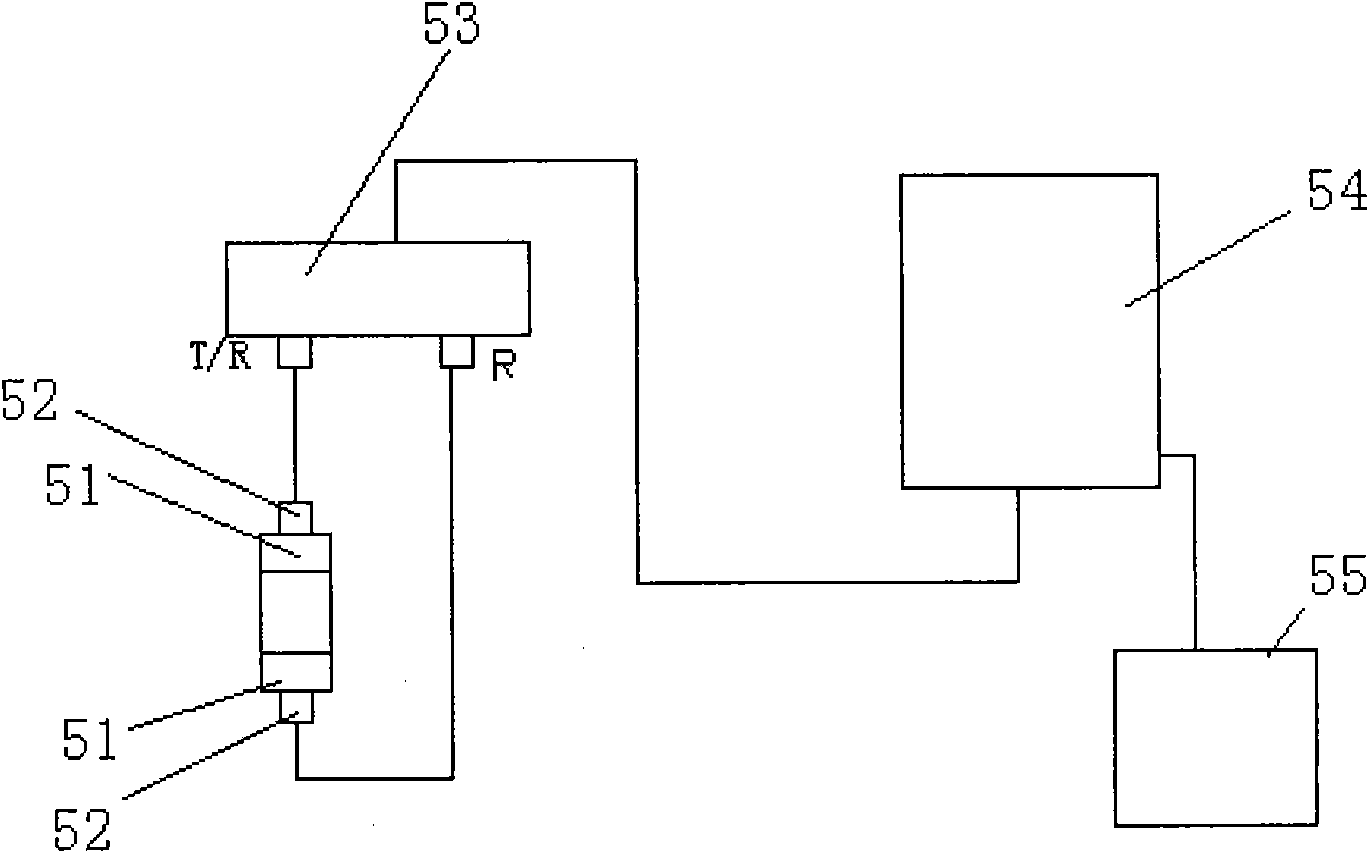

[0020] Such as figure 1 , figure 2 As shown, the measuring device of the present invention includes a high-pressure reactor 1 which can be filled with an experimental medium, and the high-pressure reactor 1 is respectively connected with a high-pressure natural gas distribution system 2, a temperature measurement system 3, a pressure measurement system 4 and an ultrasonic The sound velocity measuring system 5 and the high-pressure reactor 1 are arranged in a cooling bath 6 , and the cooling bath 6 is connected with a refrigeration compressor 7 .

[0021] The top of the high-pressure reaction kettle 1 of the present invention is provided with a kettle cover, and a handle slide bar 11 is slidably inserted on the kettle cover, and a support frame 12 is provided at the bottom of the high-pressure reaction kettle 1 . The upper part of the kettle wall of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com