Device for detecting stroke and speed of slide of forging and pressing equipment

A slider stroke and speed detection technology, which is applied in the direction of measuring devices, optical devices, and devices that measure the time required to move a certain distance, can solve the problem of low safety and reliability, large equipment vibration, and failure to meet the slider displacement speed. Requirements for detection accuracy and other issues to achieve the effect of improving safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

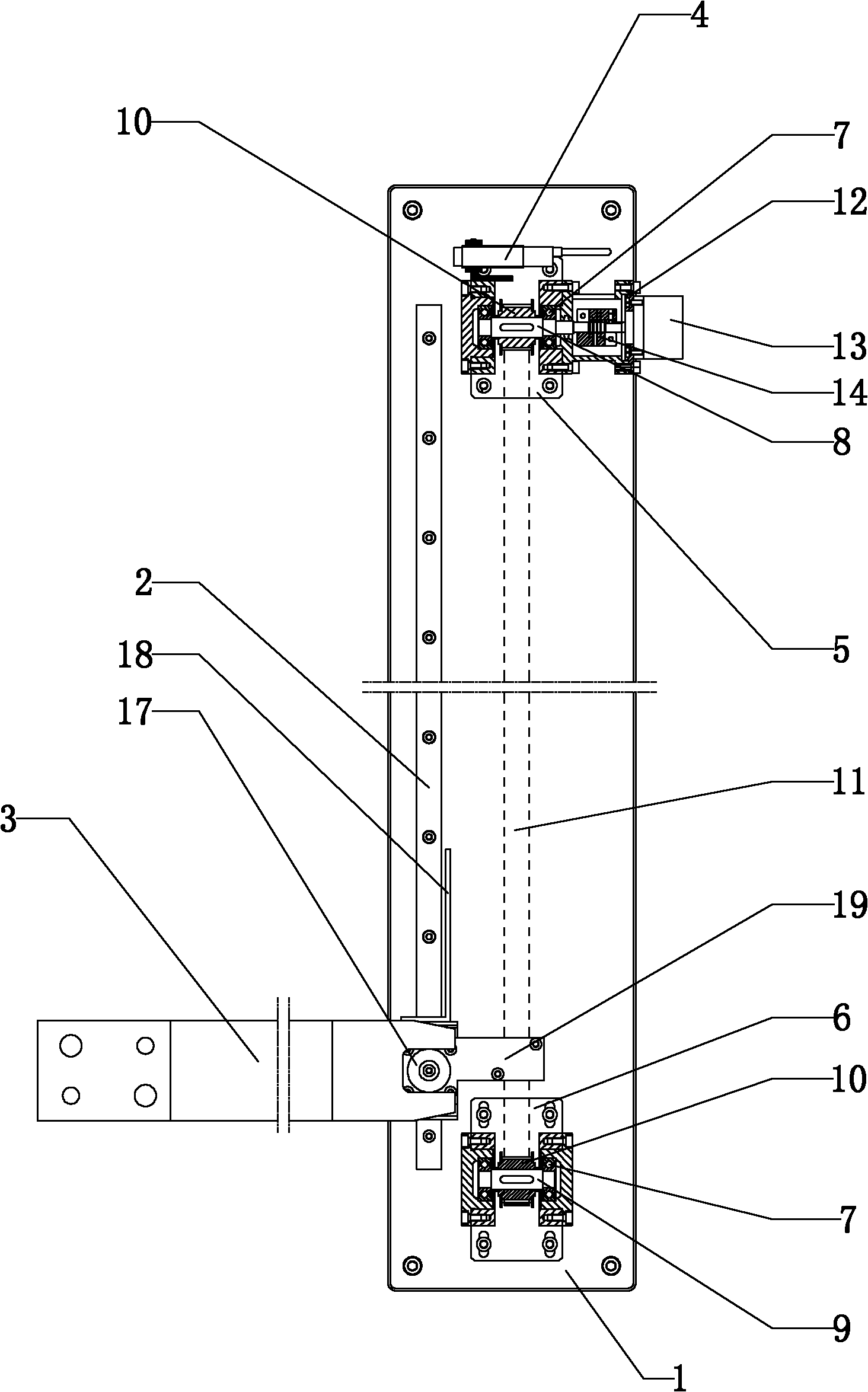

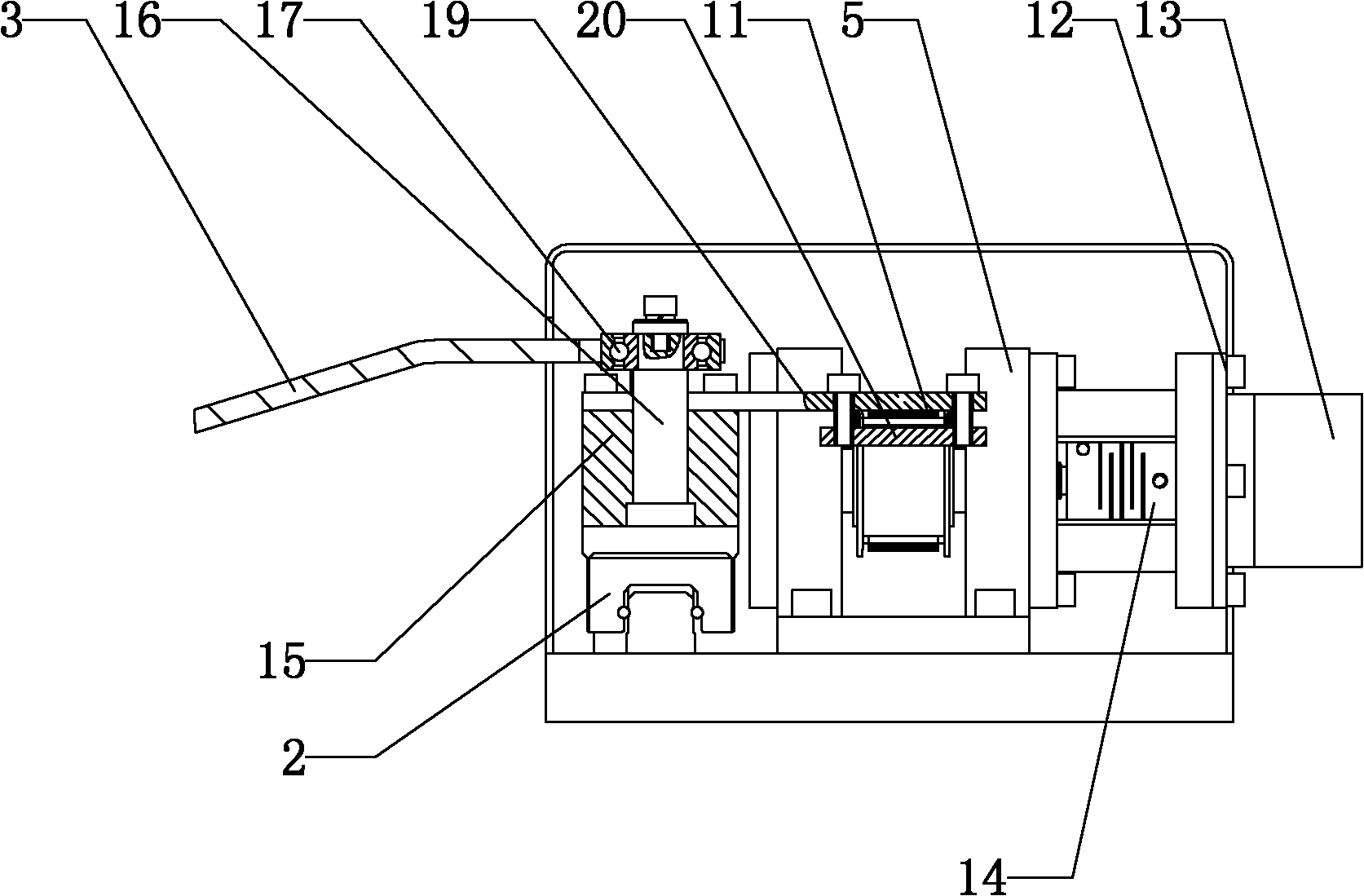

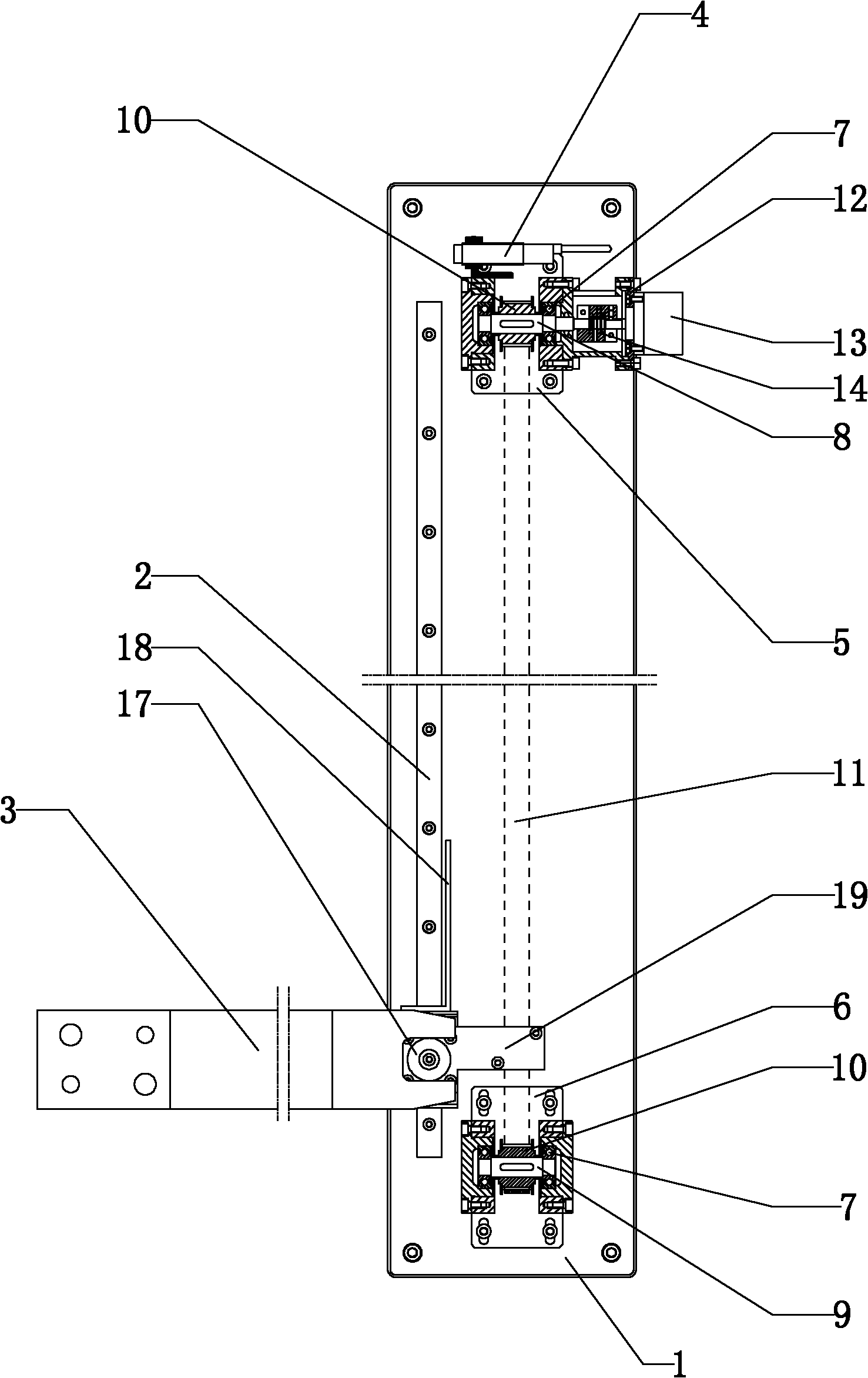

[0016] Such as Figure 1-2 As shown, a forging equipment slider stroke and speed detection device described in the embodiment of the present invention includes a base 1, a linear guide rail 2, a fixed dial 3 and a photoelectric switch 4, and the base 1 near the top and bottom An upper bearing seat 5 and a lower bearing seat 6 are provided respectively, and the inside of the upper bearing seat 5 and the lower bearing seat 6 are respectively fixed with the first shaft 8 and the second shaft 9 through the first bearing 7, and the first shaft 8 and the second shaft 9 The timing belt pulley 10 is fixed by a flat key on the top, and the timing belt 11 is connected between the two timing pulleys 10; the top of the upper bearing seat 5 is provided with a photoelectric switch 4, and the left and right positions of the photoelectric switch 4 are adjustable. The upper bearing seat 5 The right side of the encoder seat 12 is provided with an encoder seat 12, and the right side of the encod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com