Quick automatic tensioning mechanism of dynamic triple connecting rod

A tensioning mechanism and link technology, applied in mechanical equipment, transmission devices, belts/chains/gears, etc., can solve the problems of slow screw, complex structure, high processing and manufacturing costs, and improve the ability to transmit loads and improve transmission. Efficiency, low manufacturing cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

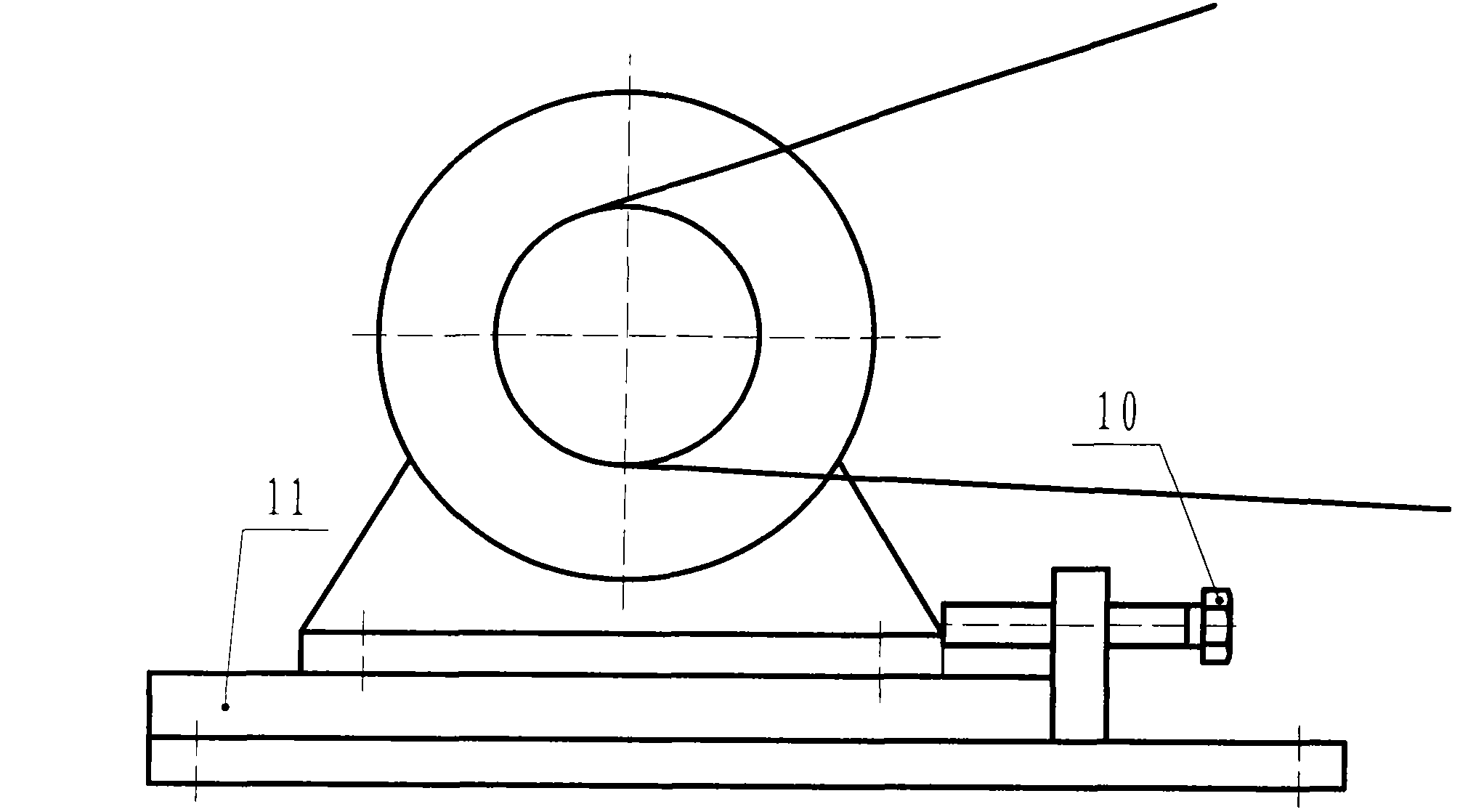

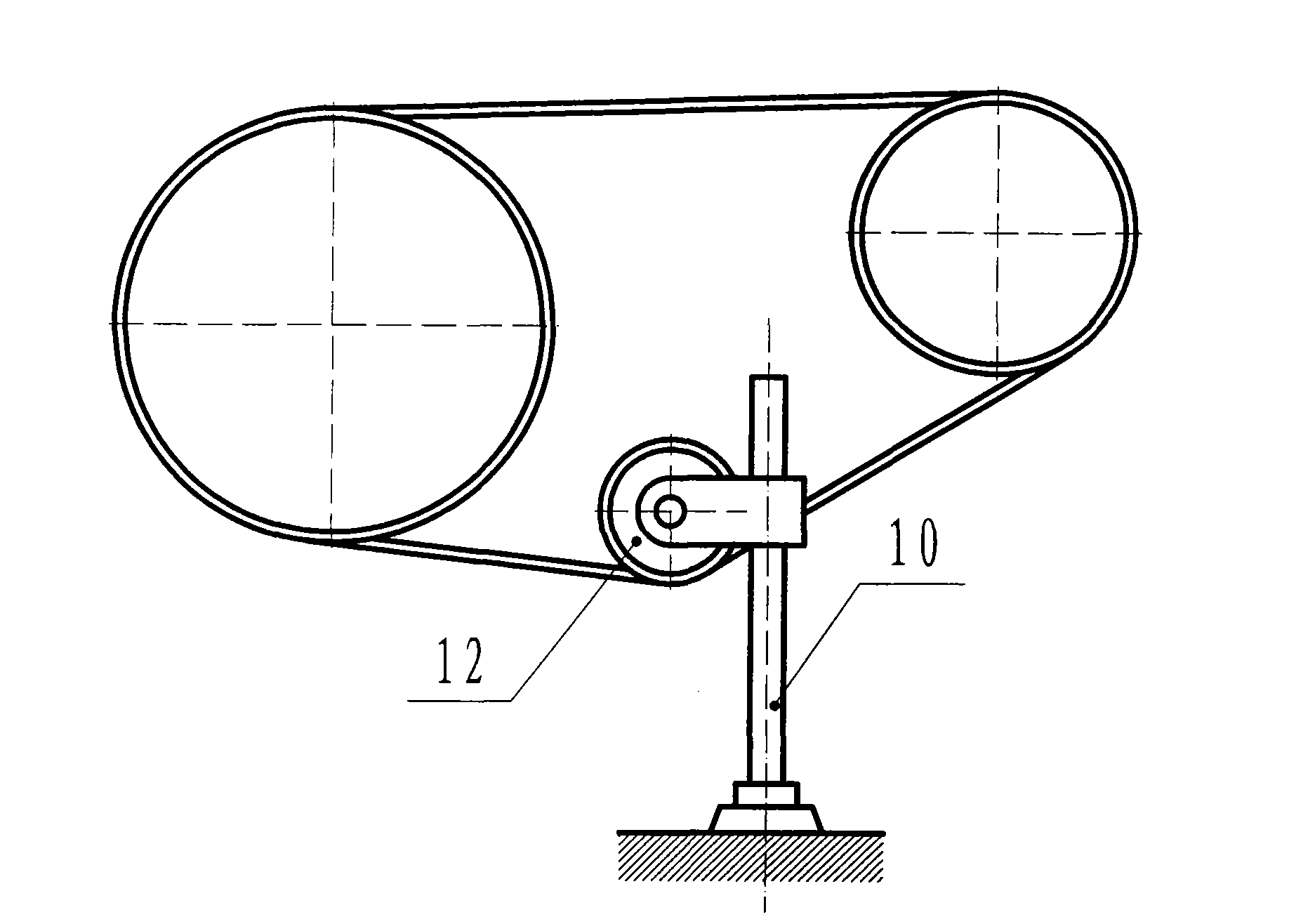

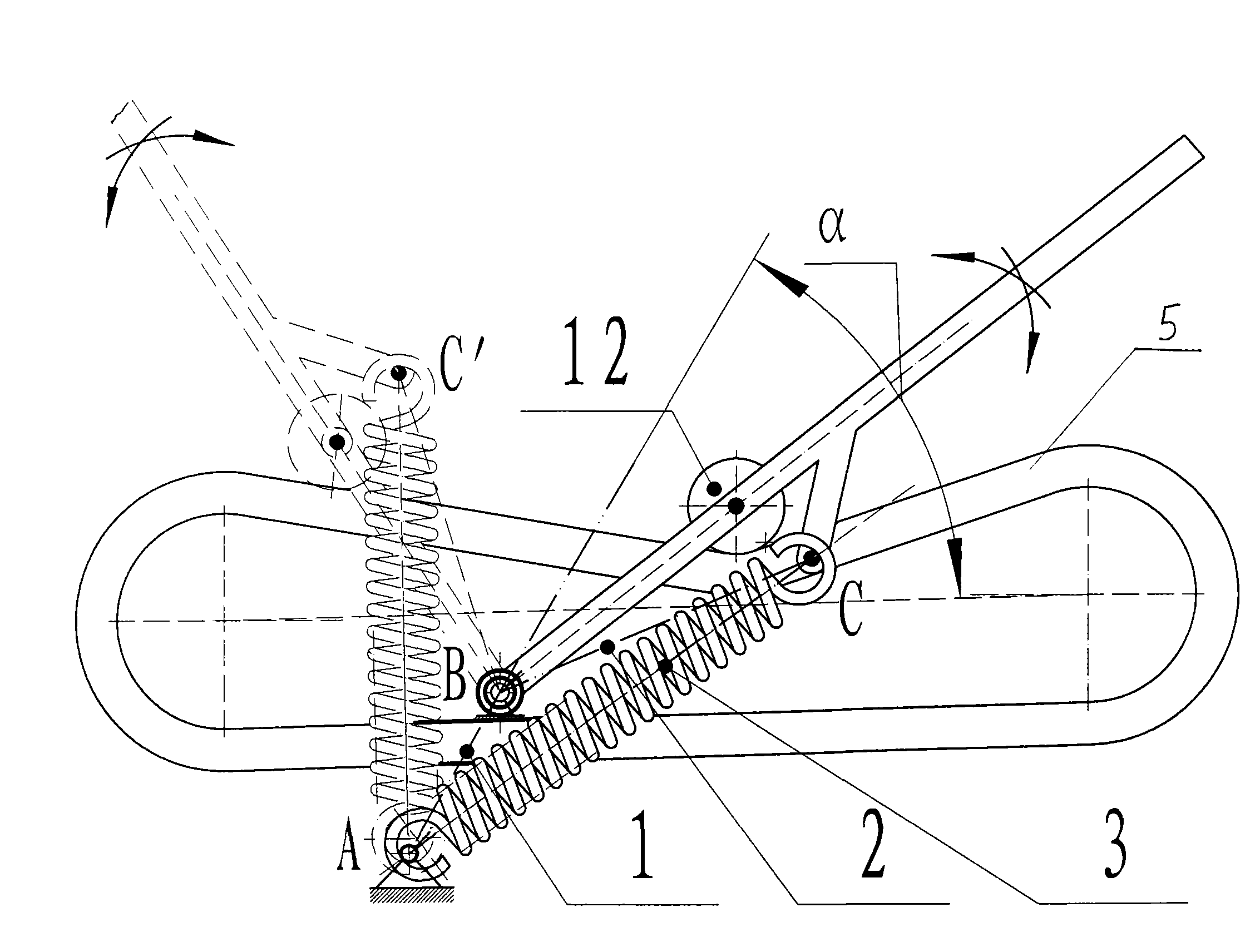

[0025] figure 1 , figure 2 , image 3 Among them, A is hinge I, and B is hinge II; hinge I and hinge II are respectively connected to different positions of frame 1, and hinge I and hinge II form connecting rod II, and its size and position are not fixed. Change; 2 is the connecting rod I, 3 is the connecting rod III, the lower end of the connecting rod I is connected to the hinge II, the middle part of the connecting rod I is connected with the cylindrical helical tension spring as the connecting rod III, and its connection point is C, and BC constitutes tension The connecting rod I and BC' in the (combined) state constitute the connecting rod I in the relaxed (off) state, the length and dimension of the connecting rod I remain unchanged, and the position can swing left and right through the movable hinge I; AC(C 1 、C 2 、C 3 ......C n ) constitutes the connecting rod III of the tensioned (combined) state, and AC' constitutes the connecting rod III of the relaxed (off) s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com