White slag refining agent for LF (Ladle Furnace) refining furnace and preparation method thereof

A refining agent and refining furnace technology, applied in the field of white slag refining agent, can solve the problem of low ability to absorb inclusions, achieve low cost, wide application range, and reduce heat radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

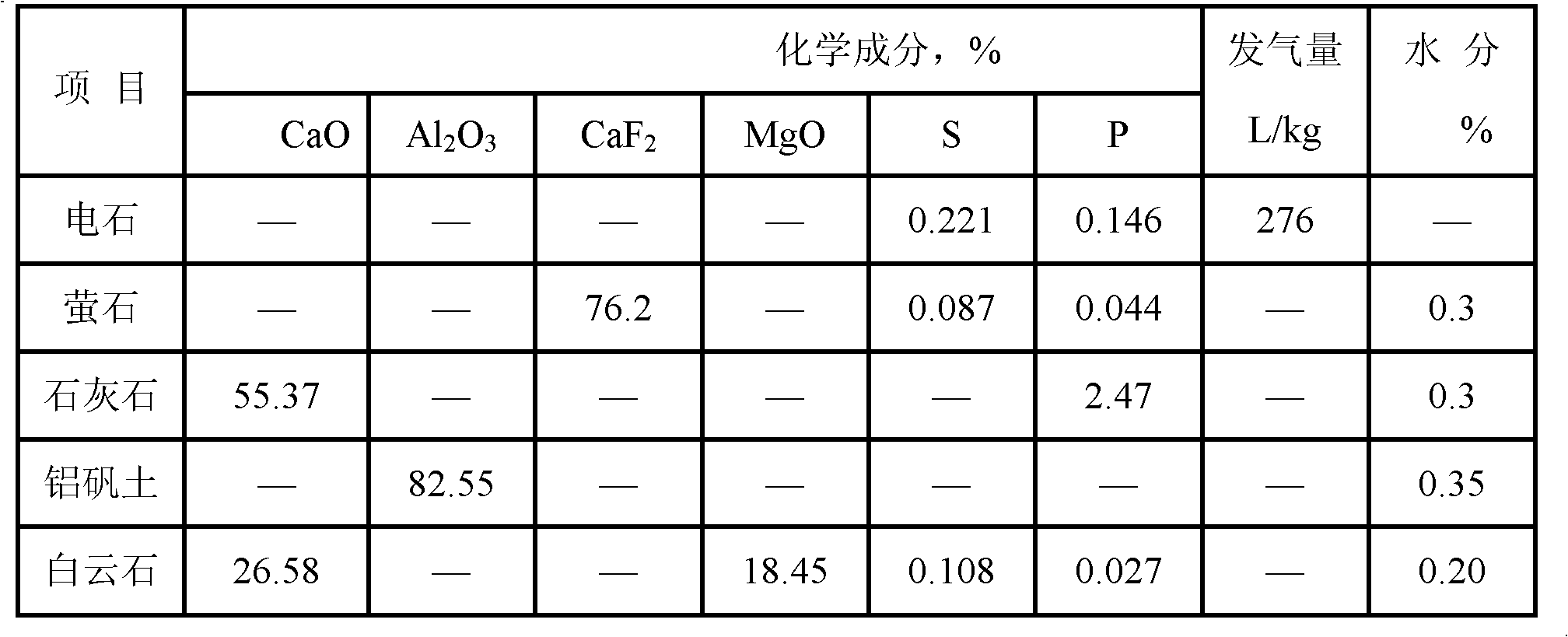

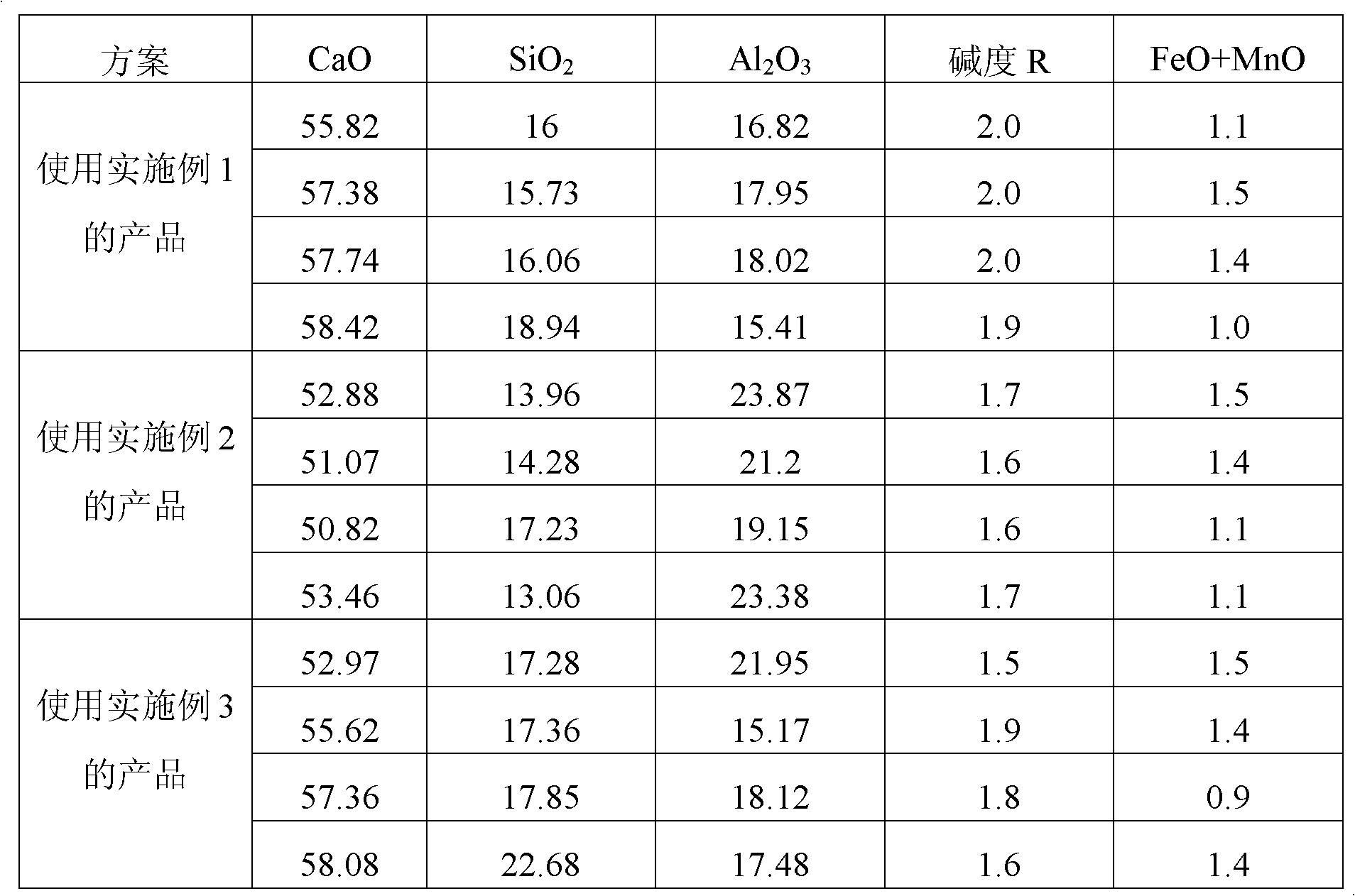

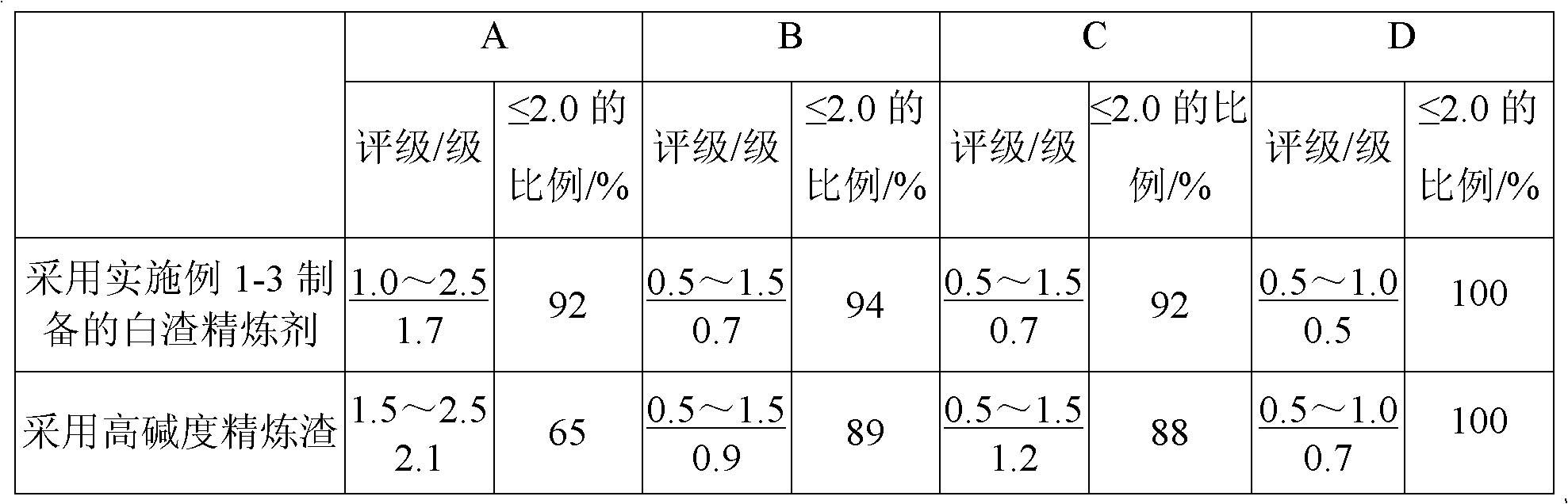

[0060] Embodiment 1 Preparation and application of white slag refining agent of the present invention

[0061] After weighing 40% by weight of calcium carbide, 14% by weight of fluorite, 30% by weight of limestone, 5% by weight of bauxite, and 11% by weight of dolomite, the weighed fluorite Stone, limestone, dolomite, and bauxite are respectively fed into the mixing mixer for mixing and stirring. After mixing and stirring for 2 minutes, calcium carbide is added to continue mixing and stirring for 4 minutes. After observing that the product has been stirred and mixed evenly to form a product, it is loaded into a woven bag lined with a plastic film from the outlet of the mixer. Sampling carried out the detection of chemical composition simultaneously (chemical composition detection sees Table 2), this white slag refining agent is applied to steelmaking LF operation, adds LF, and addition is 300kg / furnace (2.307kg / ton molten steel), observes that LF emerges The ladle slag compo...

Embodiment 2

[0062] Embodiment 2 Preparation and application of white slag refining agent of the present invention

[0063] After weighing 50% by weight of calcium carbide, 8% by weight of fluorite, 24% by weight of limestone, 6% by weight of bauxite, and 12% by weight of dolomite, the weighed fluorite Stone, limestone, dolomite, and bauxite are respectively fed into the mixing mixer for mixing and stirring. After mixing and stirring for 2 minutes, calcium carbide is added to continue mixing and stirring for 4 minutes. After observing that the product has been stirred and mixed evenly to form a product, it is loaded into a woven bag lined with a plastic film from the outlet of the mixer. At the same time, samples were taken to detect the chemical composition (see Table 2 for the chemical composition detection). This white slag refining agent was applied to the steelmaking LF process, and 300kg / furnace (2.307kg / ton molten steel) was added to the LF furnace, and the LF outbound ladle was obs...

Embodiment 3

[0064] Embodiment 3 Preparation and application of white slag refining agent of the present invention

[0065] After weighing 45% by weight of calcium carbide, 12% by weight of fluorite, 28% by weight of limestone, 5% by weight of bauxite, and 10% by weight of dolomite, the weighed fluorite Stone, limestone, dolomite, and bauxite are respectively fed into the mixing mixer for mixing and stirring. After mixing and stirring for 2 minutes, calcium carbide is added to continue mixing and stirring for 4 minutes. After observing that the product has been stirred and mixed evenly to form a product, it is loaded into a woven bag lined with a plastic film from the outlet of the mixer. At the same time, samples were taken to detect physical and chemical indicators (see Table 2 for detection). Apply this white slag refining agent to the steelmaking LF process, add 300kg / furnace to the LF furnace, (2.307kg / ton molten steel) to observe the composition of LF outbound ladle slag, See Table ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com