Unleaded solder paste and preparation method thereof

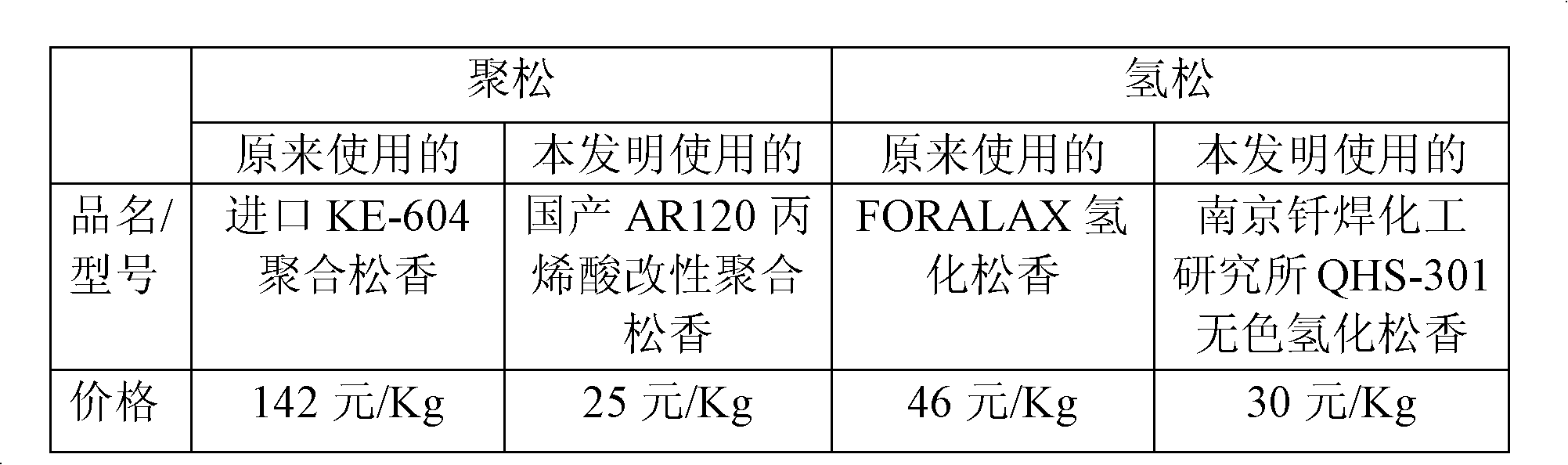

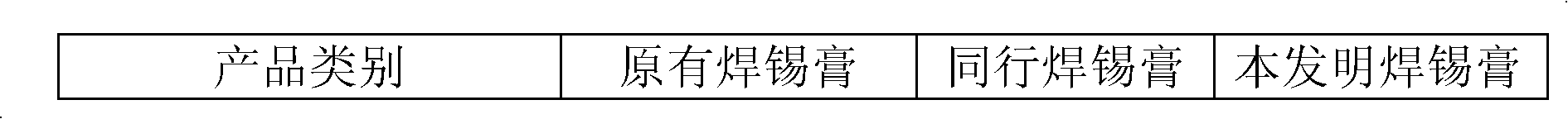

A lead-free solder paste, polymerized rosin technology, applied in welding equipment, welding media, manufacturing tools, etc., can solve the problems of poor solderability and printability, high cost of solder paste, short service life, etc., and achieve an increase in expansion rate. , the effect of increasing storage life and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Take polymerized rosin, hydrogenated rosin, modified hydrogenated castor oil, organic acid active agent, surfactant, softening agent, accelerator, antioxidant, organic solvent in weight percent as polymerized rosin: 20%, hydrogenated rosin: 10%, modified rosin Hydrogenated castor oil: 3%, organic acid active agent: 15%, surfactant 15%, softener epoxy soybean oil: 5%, accelerator: 0.2%, antioxidant: 0.2%, halogen active agent: 0.01%, organic solvent: 31.59%.

[0026] First add polymerized rosin and hydrogenated rosin into organic solvent, dissolve at about 100°C, add organic acid into the dissolved matter, add modified hydrogenated castor oil after it dissolves, add surfactant and stir evenly after cooling to about 70°C, add The accelerator and softener are stirred until dissolved, and the solder paste is obtained after cooling.

[0027] Weigh the above-mentioned solder paste into the cylinder according to the proportion of 10% flux, enter the pre-stirring state at a sp...

Embodiment 2

[0033] Get polymerized rosin, hydrogenated rosin, modified hydrogenated castor oil, organic acid active agent, surfactant, softening agent, accelerator, antioxidant, organic solvent in weight percent as polymerized rosin: 25%, hydrogenated rosin: 19%, modified rosin Hydrogenated castor oil: 5%, organic acid active agent: 10%, surfactant 4%, softener epoxy soybean oil: 7%, accelerator: 0.5%, antioxidant: 0.3%, halogen active agent: 0.01%, organic solvent: 29.19%.

[0034] First add polymerized rosin and hydrogenated rosin into organic solvent, dissolve at about 100°C, add organic acid into the dissolved matter, add modified hydrogenated castor oil after it dissolves, add surfactant and stir evenly after cooling to about 70°C, add The accelerator and softener are stirred until dissolved, and the solder paste is obtained after cooling.

[0035] Weigh the above-mentioned solder paste into the cylinder according to 11% flux, enter the pre-stirring state at a speed of 23 rpm, and t...

Embodiment 3

[0042] Take polymerized rosin, hydrogenated rosin, modified hydrogenated castor oil, organic acid active agent, surfactant, softening agent, accelerator, antioxidant, organic solvent in weight percent as polymerized rosin: 30%, hydrogenated rosin: 15%, modified Hydrogenated castor oil: 5.5%, organic acid active agent: 9%, surfactant 3%, softener: 6%, accelerator: 0.6%, antioxidant BHT: 0.35%, halogen active agent: 0.01%, Organic solvents: 30.54%.

[0043] First add polymerized rosin and hydrogenated rosin into organic solvent, dissolve at about 100°C, add organic acid into the dissolved matter, add modified hydrogenated castor oil after it dissolves, add surfactant and stir evenly after cooling to about 75°C, add The accelerator and softener are stirred until dissolved, and the solder paste is obtained after cooling.

[0044] Weigh the above-mentioned solder paste into the cylinder according to the proportion of ingredients of 11.5%, and enter the pre-stirring state at a spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com