Silver nanoparticle filled microporous carbon spheres, preparation method thereof and use thereof as catalyst

A technology of silver nanoparticles and microporous carbon, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problem of no preparation method and achieve uniform distribution , The effect of high product purity and easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Transfer 44 mL of 0.3 M sucrose aqueous solution into a 88 mL hydrothermal reaction vessel (50% full) and seal it. Then put the reaction kettle into an oven, the oven temperature is 190°C, and the reaction time is 2.25h. After the reaction was complete, it was taken out and cooled in air. Finally, the microporous carbon spheres were prepared by centrifugally cleaning with distilled water and alcohol, and drying in an oven.

[0050] figure 1 a is a transmission electron microscope (TEM) picture of the microporous carbon spheres obtained in Example 1. It can be seen that the microporous carbon spheres are relatively uniform in size, with an average diameter of about 800nm; figure 1 b is a high-resolution image of the edge of the microporous carbon sphere. Numerous nanopores are distributed on the surface of the microporous carbon sphere. It can be inferred that the carbon sphere has a microporous structure, which provides a prerequisite for ions to enter the interior...

Embodiment 2

[0052] Using the microporous carbon spheres obtained in Example 1 as a raw material, Ag-C composite spheres were prepared according to the above-mentioned method for preparing microporous carbon spheres filled with silver nanoparticles, and the reaction parameters were c=2mM, t I = 2h, P = 140W and t R = 10 min.

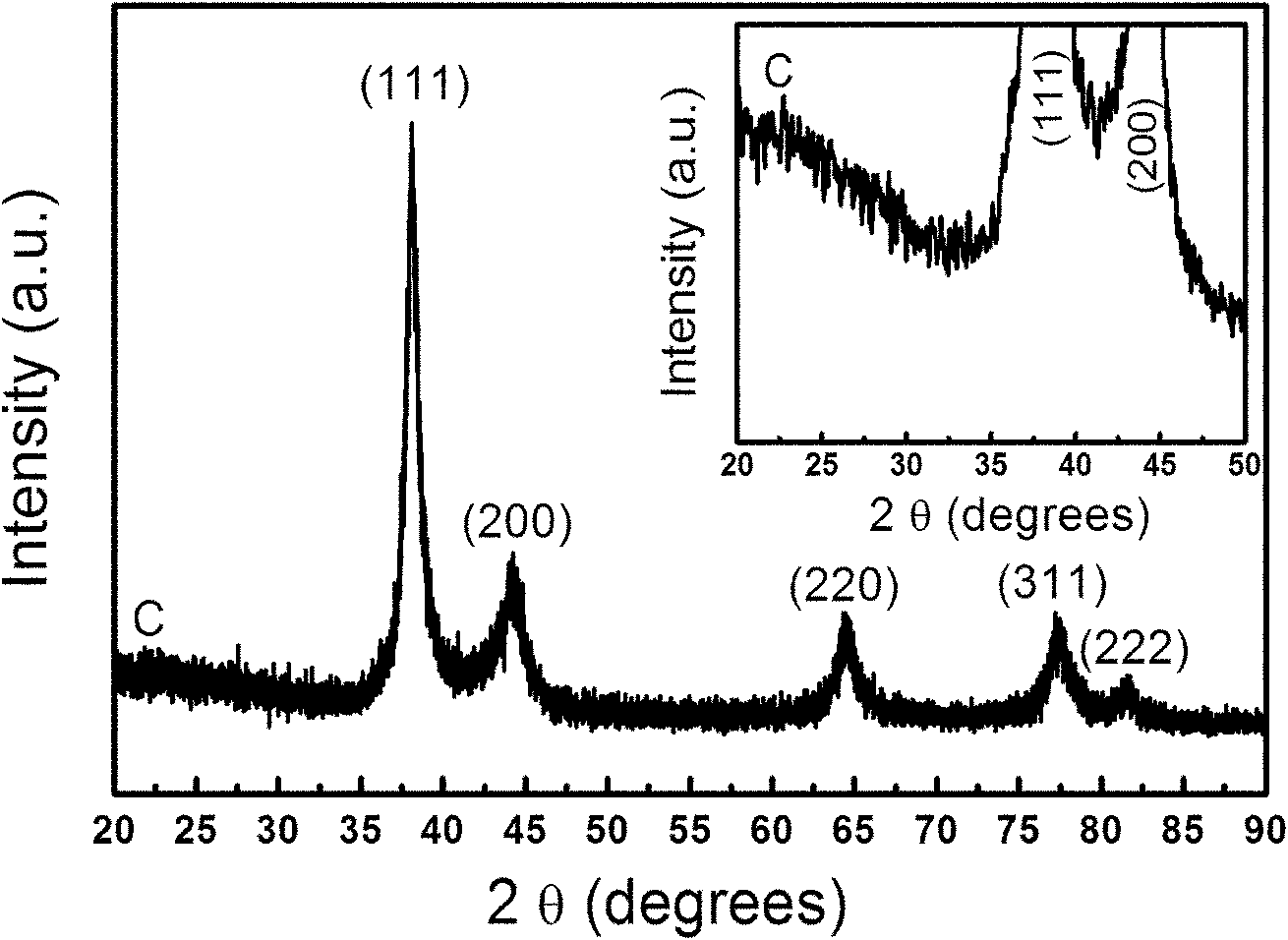

[0053] figure 2 It is the TEM pictures of different magnifications of Ag-C composite balls obtained in Example 2. From low magnification ( figure 2 a) It can be seen that a large number of small black spots are distributed inside the ball, but there are no balls on the surface. The black dots are nanoparticles with high number density but still uniform distribution. Since TEM is a two-dimensional projection image of a three-dimensional object, the center of the ball is very dark, and it seems that there are agglomerates of nanoparticles, which is due to the overlapping of two-dimensional imaging. The selected area electron diffraction (SAED) pattern of a singl...

Embodiment 3

[0057] Using the microporous carbon spheres obtained in Example 1 as a raw material, Ag-C composite spheres were prepared according to the above-mentioned preparation method of silver nanoparticles filled microporous carbon spheres, and the reaction parameters were c=0.5mM, t I = 4h, P = 140W and t R = 10 min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com