Waterless separator of high-sulfur coal and low-sulfur coal gangue blocks and sulfur blocks

A technology of high-sulfur coal and coal gangue, which is applied in the field of coal separation, can solve problems such as no successful reports in the UK, and achieve the effect of reducing energy consumption and cost of coal preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below with reference to the drawings and embodiments.

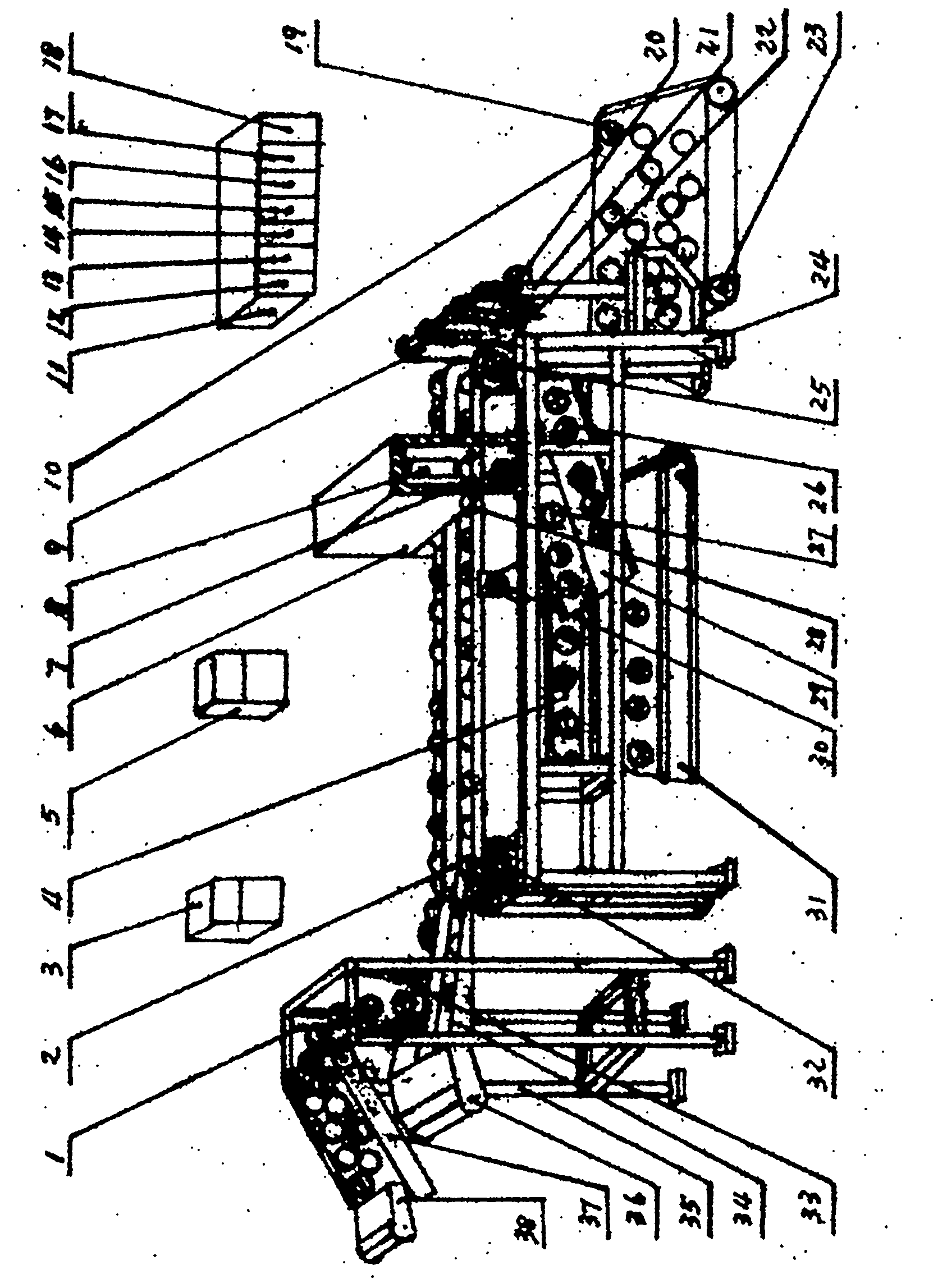

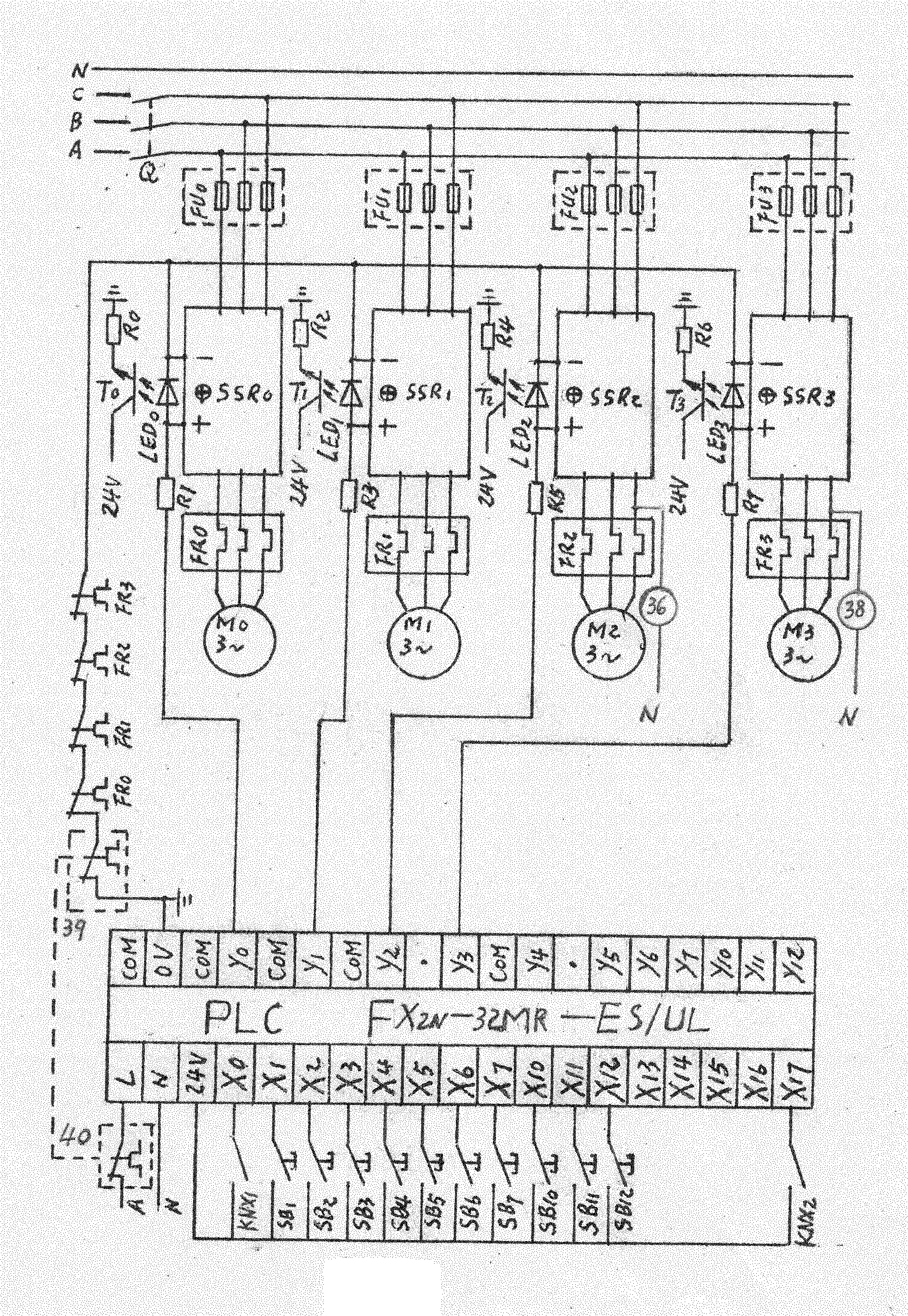

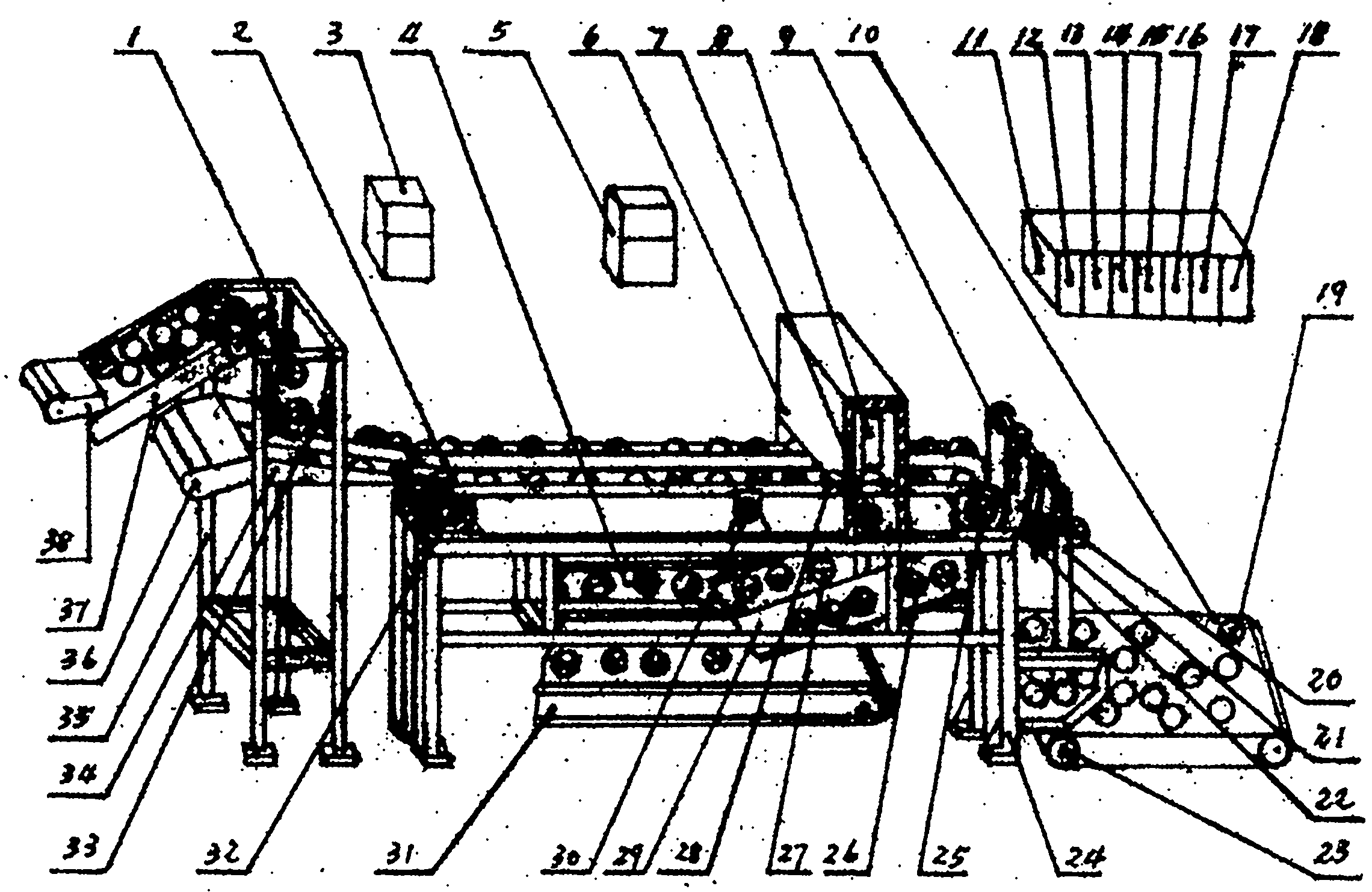

[0016] See figure 1 , The high-sulfur coal and low-sulfur coal gangue block sulfur-free separator of this embodiment is provided with a raw coal selection and classification supply system 1, an elastic double side coal feeder 2, and a high-sulfur coal gangue from the raw coal input on the left. Block sulfur separation system 9, low-sulfur coal transportation electronic scale 10, and high-sulfur coal gangue block sulfur transportation system directly below the elastic double-sided coal feeder 2, electric variable frequency speed control system 3. Programmable control type The electrical interlocking device 5, the photoelectric conversion and the electronic pulse filter 11 are sequentially installed on one side of the elastic double rib coal feeder 2. It can be seen from the figure that the probe shielding room 6 is installed on the upper part of the flexible dou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com